Modified silicon dioxide loaded polymer solid acid catalyst as well as preparation method and application thereof

A solid acid catalyst, silica technology, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem of limiting catalyst acid site utilization efficiency, agglomeration Serious, small specific surface area of the catalyst and other problems, to achieve the effect of low price, short reaction time and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

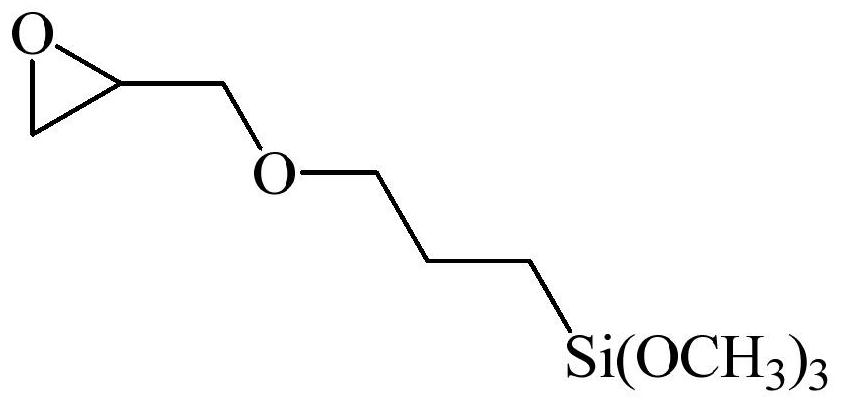

[0046] Add 1.2g of silicon dioxide, 2.4g of silane coupling agent KH560, and 50mL of cyclohexane into a three-necked flask, and stir at 25°C for 4h to obtain a modified carrier. The structure of silane coupling agent KH560 is as follows figure 1 shown.

[0047] Add 3.5g p-hydroxybenzenesulfonic acid, 1.2g paraformaldehyde, 0.4g p-toluenesulfonic acid, 6.0g absolute ethanol to the modified carrier, polycondense at 120°C for 2 hours, cool and centrifuge to get solid product.

[0048] The solid product was washed with absolute ethanol until the supernatant was transparent, and the solid product was taken out and vacuum-dried to obtain 5.2 g of a modified silica-supported polymer solid acid catalyst.

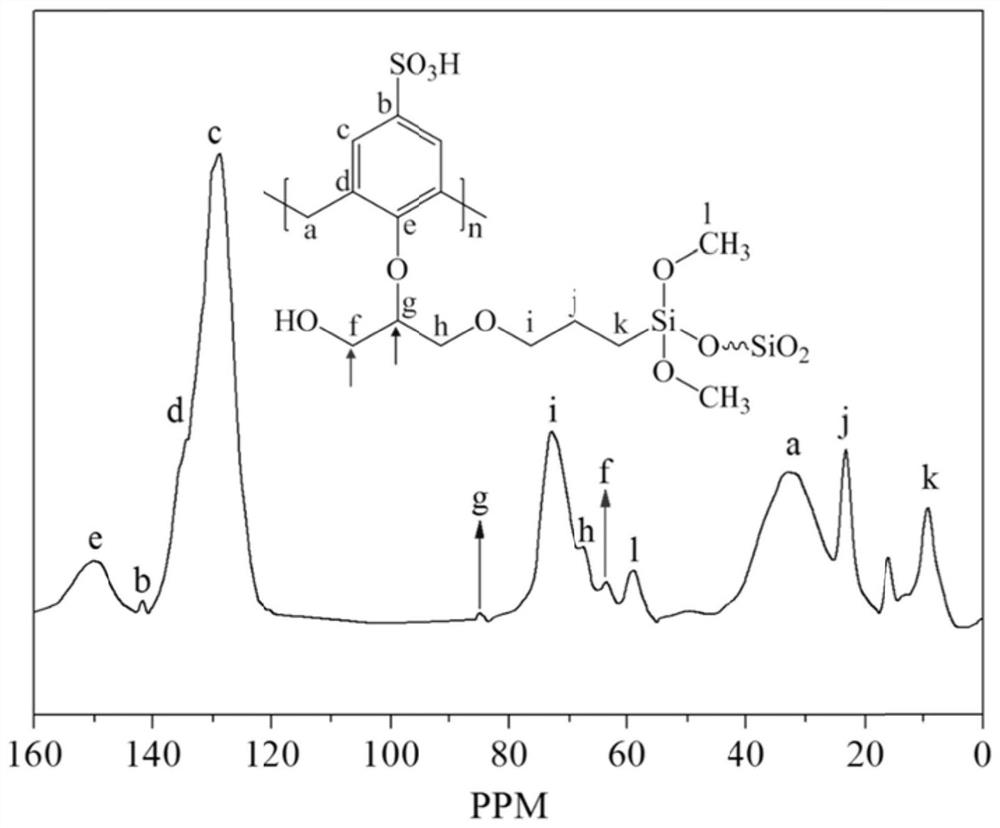

[0049] According to infrared, thermogravimetric and nuclear magnetic detection, the mass ratio of silicon dioxide, silane coupling agent KH560 and p-hydroxybenzenesulfonic acid in the obtained catalyst is 1:2:2.9.

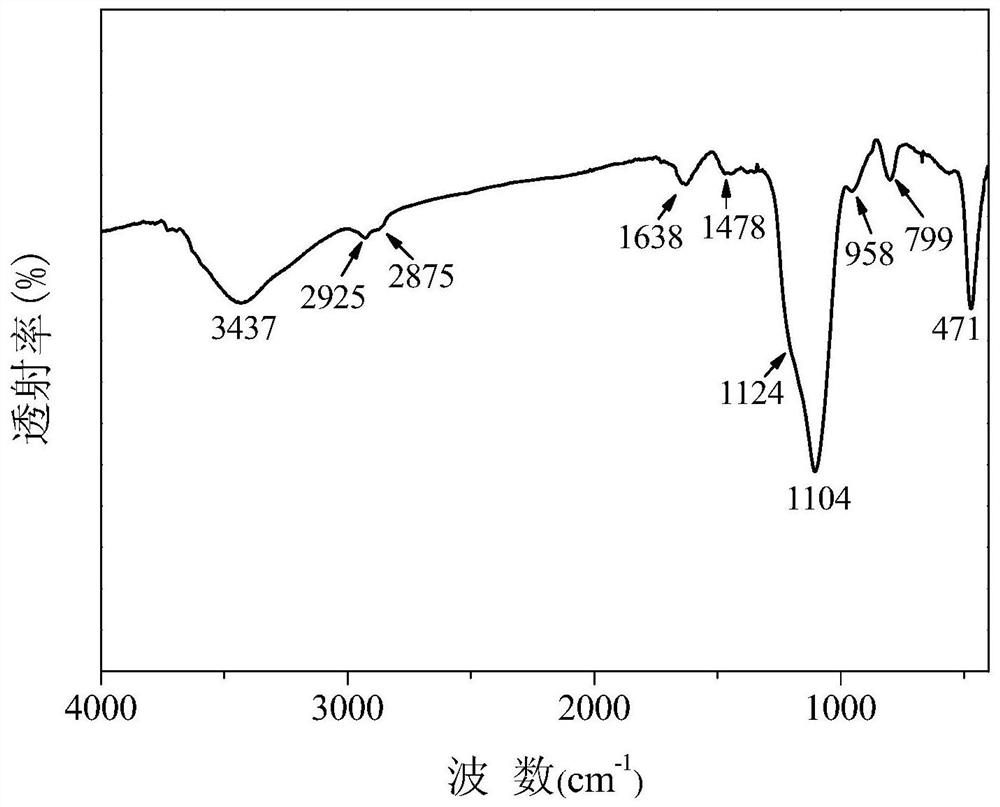

[0050] The infrared absorption spectrum of the polymer solid aci...

Embodiment 2

[0053] Referring to the preparation method of Example 1, the difference is that the mass of the silane coupling agent KH560 added is 2.0-9.4 g, that is, the mass ratio of silica and silane coupling agent is controlled to be 1:1.6-7.8 during the preparation process. The mass ratio of silicon dioxide, silane coupling agent KH560 and p-hydroxybenzenesulfonic acid in the obtained catalyst is 1:1.6-7.8:2.9.

Embodiment 3

[0055] Referring to the preparation method of Example 1, the difference is that the mass of p-hydroxybenzenesulfonic acid added during the preparation of the catalyst is 0.7 to 6.6 g, that is, the mass ratio of silicon dioxide and p-hydroxybenzenesulfonic acid is controlled to be 1:0.6 to 1:0.6 during preparation. 5.5. The mass ratio of silicon dioxide, silane coupling agent KH560 and p-hydroxybenzenesulfonic acid in the obtained catalyst is 1:2:0.6-5.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com