Rice hull ash and preparation method thereof, rice hull ash geopolymer and preparation method thereof

A technology of rice husk ash and geopolymer, which is applied in the field of building materials, can solve the problems of using geopolymer without rice husk treatment, incomplete reaction of raw materials, and loss of strength, so as to reduce crystallization sensitivity, reduce orientation degree, The effect of reducing residual carbon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

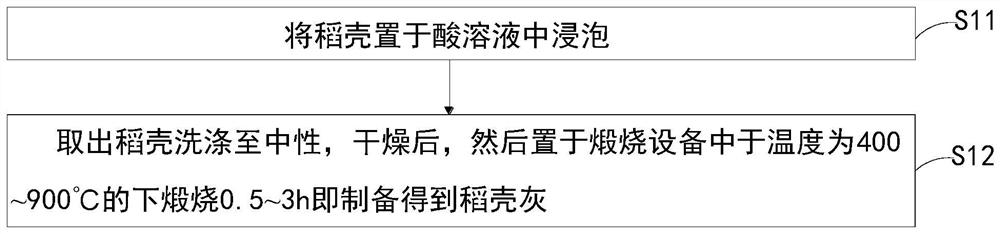

[0032] The invention provides a method for preparing rice husk ash, such as figure 1 shown, including the following steps:

[0033] S11, soaking the rice husk in an acid solution;

[0034] S12, taking out the rice husk, washing it until neutral, drying it, and then placing it in a calcination device at a temperature of 400-900° C. for 0.5-3 hours to prepare rice husk ash.

[0035] It should be noted that S11 in the examples of the present application specifically includes: adding 200 g of rice husks to 1 L of water, heating to 100°C and keeping it for 1 hour, and then putting it into an electric blast drying oven and drying it at 105°C for 2 hours before use; Prepare 1 L of sulfuric acid solution with a concentration of 0.03mol / L, and then soak the dried rice husk in the sulfuric acid solution for 0.25h;

[0036] S12 specifically includes: repeatedly rinsing the rice husks soaked in S1 with distilled water until the pH of the cleaning solution is neutral, and then drying the...

Embodiment 2

[0039] The invention provides a method for preparing rice husk ash, such as figure 1 shown, including the following steps:

[0040] S11, soaking the rice husk in an acid solution;

[0041] S12, taking out the rice husk, washing it until neutral, drying it, and then placing it in a calcination device at a temperature of 400-900° C. for 0.5-3 hours to prepare rice husk ash.

[0042]It should be noted that S11 in the examples of the present application specifically includes: adding 200 g of rice husks to 1 L of water, heating to 100°C and keeping it for 3 hours, and then putting it into an electric blast drying oven and drying it at 105°C for 2 hours before use; Prepare 1L of hydrochloric acid solution with a concentration of 1mol / L, and then soak the dried rice husk in the hydrochloric acid solution for 1.5h;

[0043] S12 specifically includes: repeatedly rinsing the rice husks soaked in S1 with distilled water until the pH of the cleaning solution is neutral, and then drying ...

Embodiment 3

[0045] The invention provides a method for preparing rice husk ash, such as figure 1 shown, including the following steps:

[0046] S11, soaking the rice husk in an acid solution;

[0047] S12, taking out the rice husk, washing it until neutral, drying it, and then placing it in a calcination device at a temperature of 400-900° C. for 0.5-3 hours to prepare rice husk ash.

[0048] It should be noted that S11 in the examples of the present application specifically includes: adding 200 g of rice husks to 1 L of water, heating to 100°C and keeping it for 5 hours, and then putting it into an electric blast drying oven and drying it at 105°C for 2 hours before use; Prepare 1 L of oxalic acid solution with a concentration of 2 mol / L, and then soak the dried rice husk in the oxalic acid solution for 3 hours;

[0049] S12 specifically includes: repeatedly rinsing the rice husks soaked in S1 with distilled water until the pH of the cleaning solution is neutral, and then drying them i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com