Method for extracting metal lead and zinc through bottom blowing oxygen-enriched self-heating smelting-electric smelting direct reduction

A self-heating smelting and metal extraction technology, which is applied in the field of metallurgy, can solve the problems of long process flow and harsh conditions, and achieve the effects of wide applicability of raw materials, avoiding reoxidation, and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

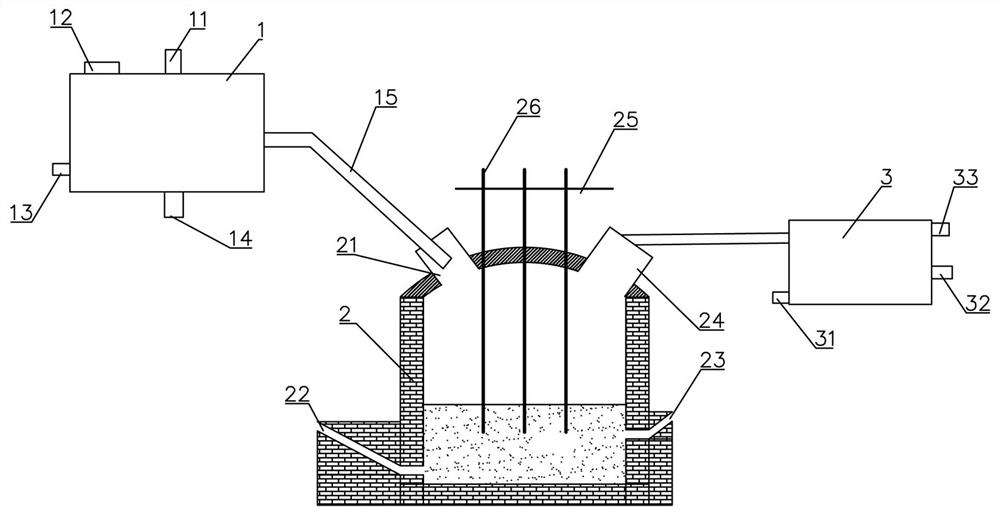

[0045] The main raw materials are lead, zinc, sulfur lead-zinc sulfide ore, lead-zinc oxide ore and flux calcium oxide, silicon dioxide to make a mixture. The composition of the mixture is Pb 45%, Zn 8%, Fe 14%, SiO 2 7%, CaO 4%, Cu 1%, S 14%, Au 10g / t, Ag1500g / t; the mixed material is sent to the bottom-blown oxidation furnace 1 through the raw material inlet 11, and the pressure is 0.6-1.3Mpa through the spray gun 14 High-pressure oxygen, the temperature in the furnace is 950-1200°C, and SO is obtained after smelting 2 Flue gas, lead liquid and oxide slag melt, in which SO 2 The flue gas consists of SO 2 The flue gas is discharged from port 12, and is made into sulfuric acid after the steps of waste heat boiler and electric dust collection.

[0046] The oxide slag melt is sent into the electric smelting reduction furnace 2 through the airtight chute 15 from the feed port 21, and coal, silicon dioxide, and calcium oxide are added. The addition of coal is 7% of the oxide sl...

Embodiment 2

[0050] The main raw materials are lead, zinc, sulfur lead-zinc sulfide ore, lead-zinc oxide ore and flux calcium oxide, silicon dioxide to make a mixture. The composition of the mixture is Pb 45%, Zn 8%, Fe 14%, SiO 2 7%, CaO 4%, Cu 1%, S 14%, Au 10g / t, Ag1500g / t; the mixed material is sent to the bottom-blown oxidation furnace 1 through the raw material inlet 11, and the pressure is 0.6-1.3Mpa through the spray gun 14 High-pressure oxygen, the temperature in the furnace is 950-1200°C, and SO is obtained after smelting 2 Flue gas, lead liquid and oxide slag melt, in which SO 2 The flue gas consists of SO 2 The flue gas is discharged from the port 12, and is made into sulfuric acid after the steps of waste heat boiler and electric dust collection;

[0051] The oxidized slag melt is sent into the electric melting reduction furnace 2 through the closed chute 15 from the feed port 21, and coal, silicon dioxide, calcium oxide and cold material containing lead-zinc oxide are adde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com