Transition metal doped anode catalyst as well as preparation method and application thereof

A transition metal and catalyst technology, which is applied in the field of transition metal-doped anode catalysts and their preparation, can solve the problems of decreased catalyst activity, non-corrosion-resistant carbon support materials, and the inability of commercial platinum carbon to meet large-scale commercial promotion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a transition metal-doped anode catalyst, comprising the following steps:

[0038] Treating carbon nanotubes with acetone and sulfuric acid to obtain pretreated carbon nanotubes;

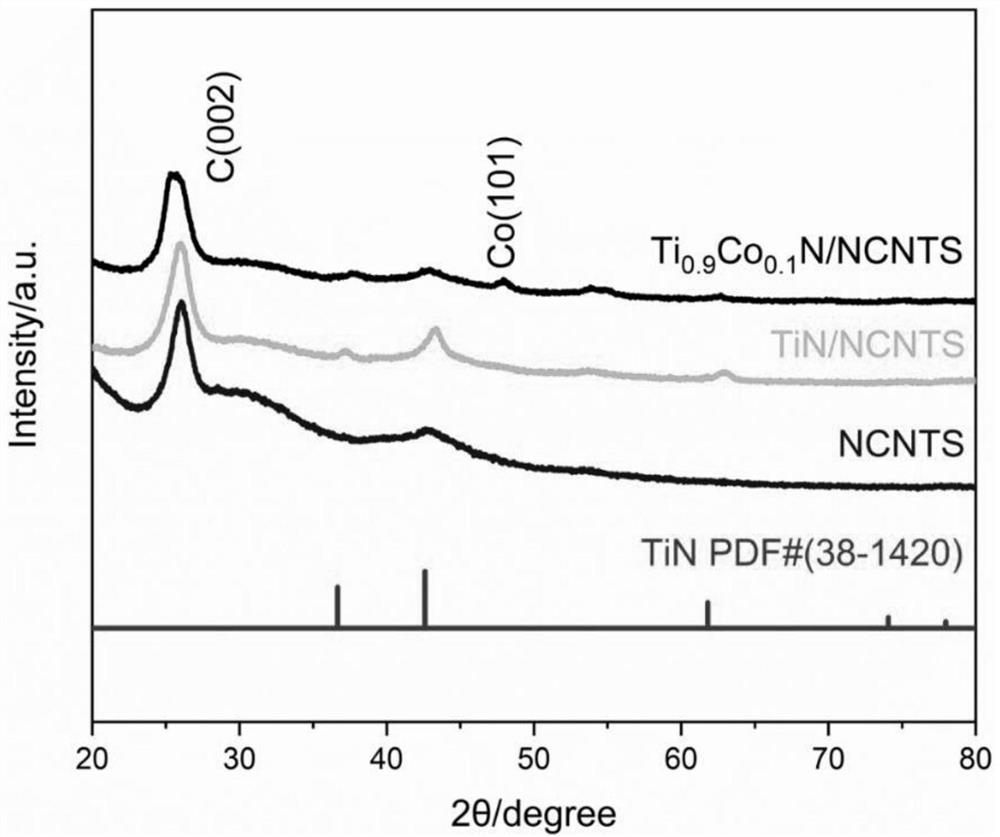

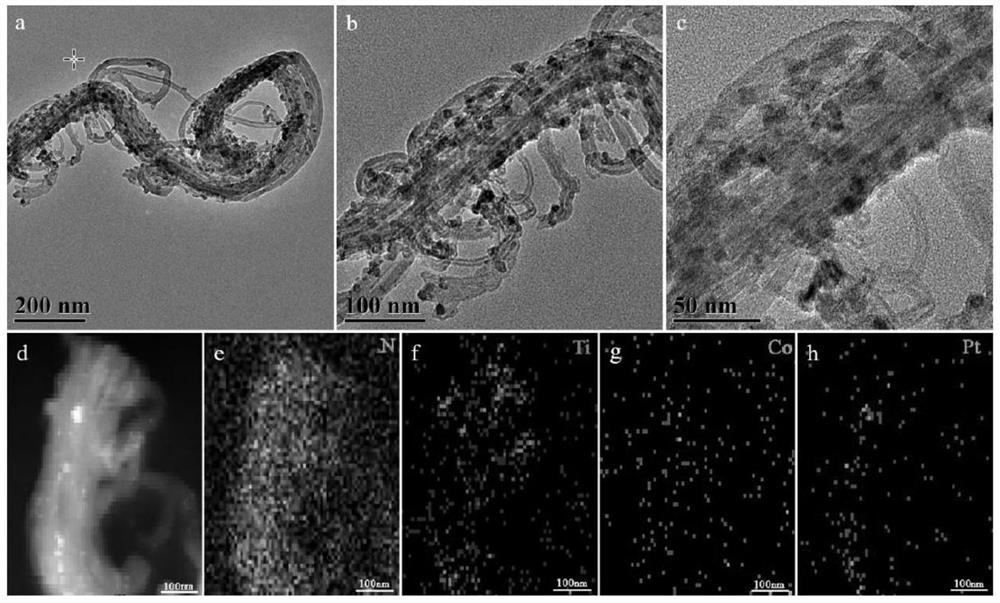

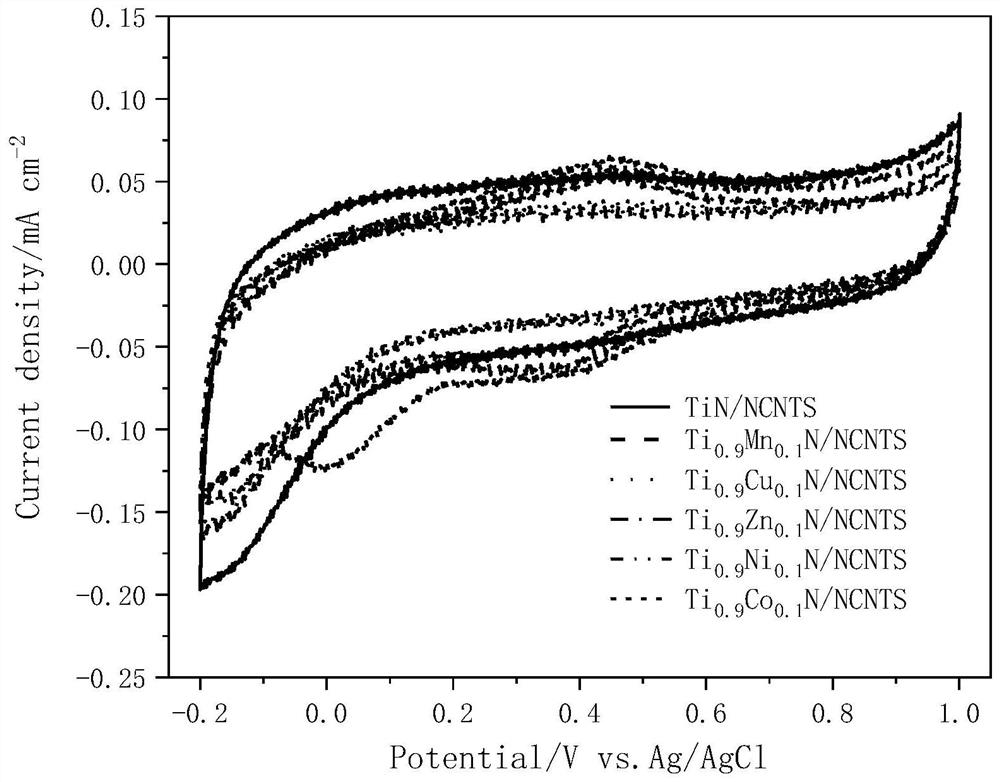

[0039] Alcohol solvent, tetra-n-butyl titanate, stabilizer, acetate metal salt and pretreated carbon nanotubes were mixed under organic acid conditions, heated to obtain a precursor, and then calcined in an ammonia atmosphere to obtain TiMN / NCNTs, M is a transition metal;

[0040] Platinum is deposited on the TiMN / NCNTs by pulse electrodeposition to obtain TiMN@Pt / NCNTs.

[0041] The invention treats carbon nanotubes with acetone and sulfuric acid to obtain pretreated carbon nanotubes. In the invention, acidified carbon nanotubes are obtained after the carbon nanotubes are treated with acetone and sulfuric acid. The carbon nanotubes may be single-walled carbon nanotubes or multi-walled carbon nanotubes. The diameter of the carbon nanotube is 10...

Embodiment 1

[0070] (1) Pretreatment of carbon nanotubes:

[0071] 600 mg of multi-walled carbon nanotubes were put into a beaker, soaked in 200 ml of acetone, and stirred at room temperature for 12 hours. The above solution was washed and filtered with deionized water, and dried in a vacuum oven at 60°C. Put the dried carbon nanotubes into 6mol·L -1 The sulfuric acid solution was stirred in an oil bath at 80°C for 10 hours. Finally, it was filtered and washed with deionized water until neutral, and dried in a vacuum oven at 60°C.

[0072] (2) Preparation method of TiMN / NCNTs:

[0073] 50 mg of pretreated carbon nanotubes were added to 30 ml of absolute ethanol, stirred for 20 minutes, ultrasonicated for 20 minutes, a mixed solution of 5 ml of deionized water and 4.5 ml of benzyl alcohol was added dropwise, and stirred for 20 minutes. While maintaining stirring, slowly add 20 ml of absolute ethanol, 10 ml of glacial acetic acid, 15 μl of a mixed solution of tetra-n-butyl titanate and ma...

Embodiment 2

[0079] The difference from Example 1 is that copper acetate is used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com