Preparation method of taurine intermediate sodium taurate and preparation method of taurine

A technology of sodium taurine and taurine, applied in the direction of sulfonic acid preparation, sulfonate preparation, chemical instruments and methods, etc., can solve the problems of separation difficulty, high production cost, equipment blockage, etc., and achieve cost reduction and saving Energy, concentration-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

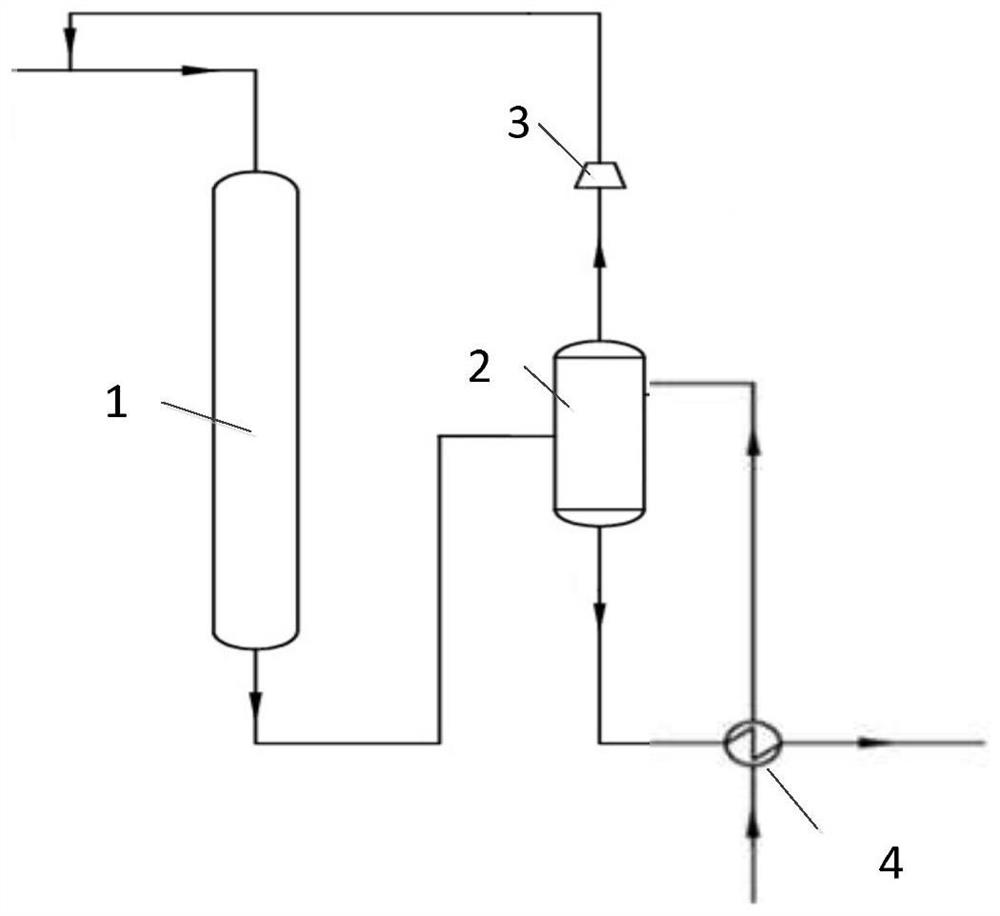

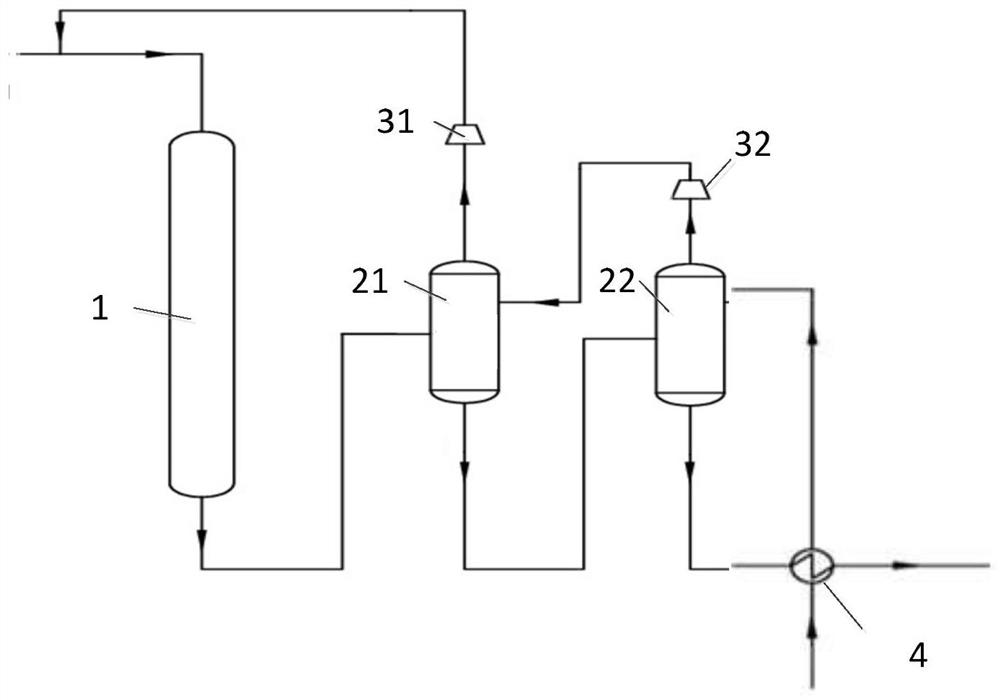

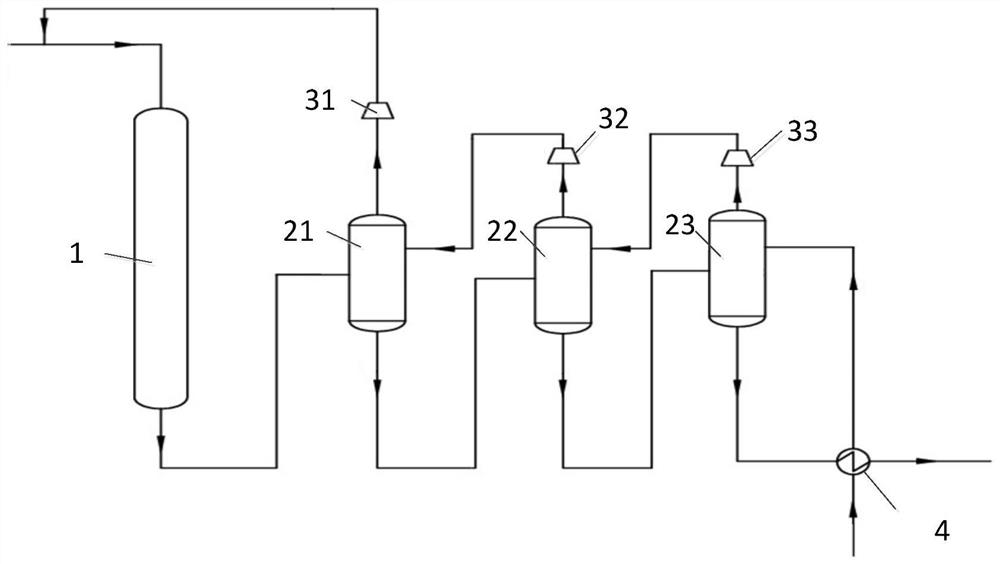

Image

Examples

preparation example Construction

[0067] The invention provides a preparation method of sodium taurate, a taurine intermediate. The preparation method comprises the following steps:

[0068] S1, providing sodium isethionate and ammonia source;

[0069] S2, placing the sodium isethionate and the ammonia source in an ammonolysis reactor for ammonolysis reaction to obtain a mixture containing the taurine intermediate sodium taurate, wherein the ammonia source The mol ratio of ammonia to the sodium isethionate is more than 25:1.

[0070] In step S1, the ammonia in the ammonia source is used as an aminating agent. The ammonia source is at least one of ammonia water mixture and liquid ammonia. The mass fraction of ammonia in the ammonia-water mixture is 20%-30%. The reason why the mol ratio of the ammonia in the ammonia source to the sodium isethionate is set to be more than 25:1 is because considering that the higher the ratio of ammonia in the system, the more the positive reaction direction is promoted, The ...

Embodiment 1

[0121] Add 200kg of ammonia water with a concentration of about 25% and 101kg of liquid ammonia (the molar ratio of ammonia to sodium isethionate is 25:1) to 170kg of sodium isethionate aqueous solution with a concentration of about 15% to form a mixture, and the mixture is added After the pressure reaches 18Mpa, it is preheated to 280°C by the preheater, and then enters the ammonolysis reactor for reaction. The ammonolysis reaction temperature is 280°C, the pressure is 18MPa, and after 30 minutes of reaction, the ammonolysis solution removes ammonia to obtain sodium taurate The solution is 320Kg, the content of sodium taurine is 7.2%, and the calculated yield of sodium taurine is 90.9%.

Embodiment 2

[0123] Add 200kg of ammonia water with a concentration of about 25% and 372kg of liquid ammonia (the molar ratio of ammonia to sodium isethionate is 70:1) to 170kg of sodium isethionate aqueous solution with a concentration of about 15% to form a mixture, and the mixture is added After the pressure reaches 18Mpa, it is first preheated to 280°C by the preheater, and then enters the ammonolysis reactor for reaction. The ammonolysis reaction temperature is 280°C, and the pressure is 17.8MPa. After 30 minutes of reaction, the ammonolysis solution removes ammonia to obtain taurine The sodium solution is 319Kg, the sodium taurine content is 7.82%, and the calculated yield of sodium taurine is 98.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com