Eco-friendly production process of iodate

A green production and iodate technology, which is applied in the field of green iodate production technology, can solve problems such as increased energy consumption, safety accidents, and impact on product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Potassium Iodate:

[0043]Add 3600mL of deionized water to the 5000mL reaction kettle, put in 632g of lithium hydroxide (≥56.5%), 1910g of iodine, and 12.08g of potassium dichromate, take samples to detect the concentration and pH of lithium ions and potassium dichromate, and add an appropriate amount according to the test results Water, lithium hydroxide, iodine, potassium dichromate, adjust the final lithium ion mass concentration to 1.7%, add potassium dichromate to adjust the potassium dichromate mass concentration to 0.2%, adjust the pH to 10.1, configure 3 batches of electrolysis according to this ratio The solution is transferred to the electrolyte storage tank for later use.

[0044] Part of the configured electrolyte is put into the electrolysis device, the temperature is raised to 80°C, the cycle is started, the voltage is set to 3.8V, the electrolysis is carried out until the mass concentration of iodate is 18%, and the electrolyte is continuou...

Embodiment 2

[0050] The preparation of potassium iodate (mother solution applies mechanically):

[0051] Get the metathesis mother liquor 4000mL that obtains in embodiment 1, detect lithium ion, potassium ion, potassium dichromate concentration, pH value, add appropriate amount of water, lithium hydroxide and iodine fine-tuning according to detection result, make the lithium ion mass concentration in the solution be 0.8 %, potassium ion mass concentration ≤ 1.3%, potassium dichromate mass concentration 0.2%, adjust pH to 9.6, configure 3 batches and transfer to electrolyte storage tank for standby.

[0052] In embodiment 1, add above electrolytic solution continuously in the electrolytic circulation system containing 18% of iodate root that has been stabilized, control electrolytic anode and cathode voltage 3.8V, and extract electrolysis completion liquid continuously from discharge opening, by electrolytic solution feeding valve, Adjust the flow rate, control the mass concentration of iod...

Embodiment 3

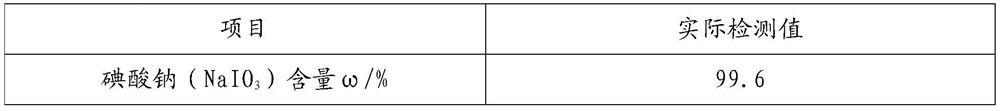

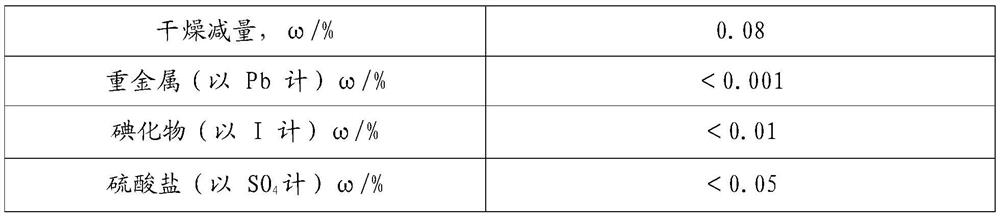

[0058] Preparation of sodium iodate:

[0059] Add 3600mL of deionized water to the 5000mL reactor, add lithium hydroxide and iodine, adjust the mass concentration of lithium ions to 1.7%, add sodium dichromate to adjust the mass concentration of sodium dichromate to 0.15%, and adjust the pH to 10.6, according to this ratio Configure 4 batches of electrolyte and transfer it to the electrolyte storage tank for standby.

[0060] Part of the configured electrolyte is put into the electrolysis device, the temperature is raised to 80°C, the cycle is started, the voltage is set to 3.7V, the electrolysis is carried out until the mass concentration of iodate is 16%, and the electrolyte is continuously added to the electrolysis device, and continuously collected from the outlet. The finished electrolysis solution is discharged, the flow rate is adjusted through the electrolyte feeding valve, and the mass concentration of iodate in the finished electrolysis solution is controlled to be 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com