Lightly-doped substrate, substrate with selective emitter, and solar cell and preparation method and application thereof

A lightly doped, substrate technology, applied in the field of solar cells, can solve the problems of lowering the reaction temperature, reducing the amount of carrier gas, uneven doping square resistance, etc., and achieves the effect of simple preparation method, easy realization and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

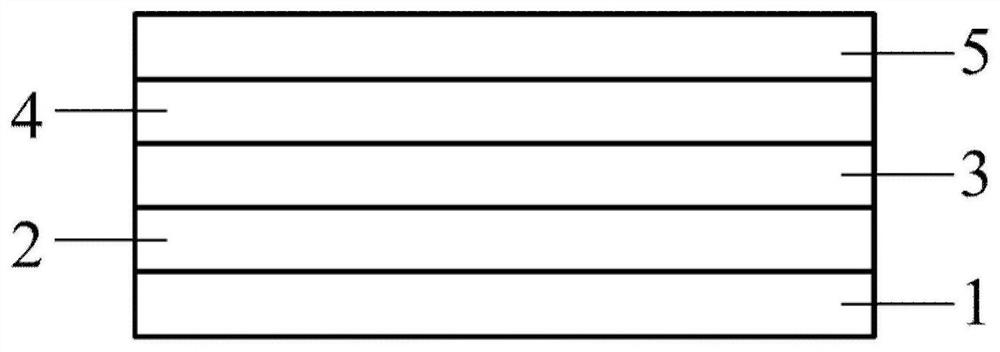

[0081] This embodiment provides a lightly doped substrate, such as figure 1 As shown, the lightly doped substrate includes a P-type silicon layer 1, an N-type silicon layer 2, a first phosphosilicate glass layer 3, an oxide layer 4 and a second phosphosilicate glass layer 5 connected in sequence, wherein the P-type silicon layer The thickness of layer 1 is 160 μm, the thickness of N-type silicon layer 2 is 0.3 μm, the thickness of the first phosphosilicate glass layer 3 is 20 nm, and the phosphorus content in the first phosphosilicate glass layer 3 is 6×10e 20 cm -3 , the thickness of the oxide layer 4 is 40nm, the thickness of the second phosphosilicate glass layer 5 is 20nm, and the phosphorus content in the second phosphosilicate glass layer 5 is 8×10e 20 cm -3 .

[0082] This embodiment also provides a method for preparing a lightly doped substrate, the preparation method comprising the following steps:

[0083] A. Entering the boat: Pre-texture the P-type silicon wafe...

Embodiment 2

[0094] This embodiment provides a lightly doped substrate, which includes a P-type silicon layer, an N-type silicon layer, a first phosphosilicate glass layer, an oxide layer, and a second phosphosilicate glass layer connected in sequence, wherein The thickness of the P-type silicon layer is 180 μm, the thickness of the N-type silicon layer is 0.1 μm, the thickness of the first phosphosilicate glass layer is 30 nm, and the content of phosphorus in the first phosphosilicate glass layer is 5×10e 20 cm -3 , the thickness of the oxide layer is 20nm, the thickness of the second phosphosilicate glass layer is 10nm, and the phosphorus content in the second phosphosilicate glass layer is 7×10e 20 cm -3 .

[0095] This embodiment also provides a method for preparing a lightly doped substrate, the preparation method comprising the following steps:

[0096] A. Entering the boat: Pre-texture the P-type silicon wafer layer to obtain the textured silicon wafer, and then put the textured ...

Embodiment 3

[0107] This embodiment provides a lightly doped substrate, which includes a P-type silicon layer, an N-type silicon layer, a first phosphosilicate glass layer, an oxide layer, and a second phosphosilicate glass layer connected in sequence, wherein The thickness of the P-type silicon layer is 140 μm, the thickness of the N-type silicon layer is 0.5 μm, the thickness of the first phosphosilicate glass layer is 10 nm, and the phosphorus content in the first phosphosilicate glass layer is 7×10e 20 cm -3 , the thickness of the oxide layer is 60nm, the thickness of the second phosphosilicate glass layer is 30nm, and the phosphorus content in the second phosphosilicate glass layer is 9×10e 20 cm -3 .

[0108] This embodiment also provides a method for preparing a lightly doped substrate, the preparation method comprising the following steps:

[0109] A. Entering the boat: Pre-texture the P-type silicon wafer layer to obtain the textured silicon wafer, and then put the textured sil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com