Environment-friendly waterproof material and preparation method thereof

A waterproof material and environmental protection technology, applied in the field of waterproof materials, can solve the problems of poor compatibility, long-term use performance stability needs to be further improved, complex preparation components, etc., to achieve a wide range of raw material sources, significant waterproof effect, and good comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

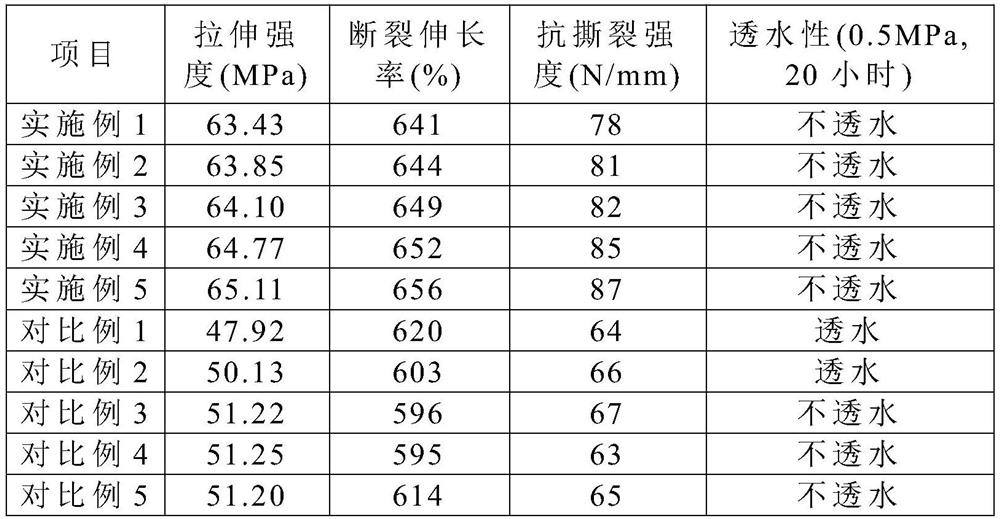

Examples

Embodiment 1

[0032] An environmentally friendly waterproof material, characterized in that it is prepared from the following raw materials in parts by weight: 30 parts of 3,6-dibromo-9-vinylcarbazole / bisphenol S polycondensate, vinyl-terminated polyurethane 15 parts of polymer modified coal tar pitch, 10 parts of vinyl-terminated nitrile rubber, 3 parts of hyperbranched polysiloxane, and 0.07 part of azobisisobutyronitrile.

[0033] The preparation method of the 3,6-dibromo-9-vinylcarbazole / bisphenol S polycondensate comprises the following steps: 3,6-dibromo-9-vinylcarbazole, bisphenol S, 1, 4 Add naphthoquinone and cesium carbonate to a three-necked flask connected with a water separator, then add dimethyl sulfoxide and toluene, stir and react at 125°C for 3 hours in a nitrogen atmosphere, and remove the water generated during the reaction through the water separator and toluene, after removing all the water, slowly raise the reaction temperature to 140°C, continue to stir the reaction f...

Embodiment 2

[0037] An environmentally friendly waterproof material, characterized in that it is prepared from the following raw materials in parts by weight: 35 parts of 3,6-dibromo-9-vinylcarbazole / bisphenol S polycondensate, vinyl-terminated polyurethane 17 parts of polymer modified coal tar pitch, 11 parts of vinyl-terminated nitrile rubber, 4 parts of hyperbranched polysiloxane, and 0.08 part of azobisisoheptanonitrile.

[0038] The preparation method of the 3,6-dibromo-9-vinylcarbazole / bisphenol S polycondensate comprises the following steps: 3,6-dibromo-9-vinylcarbazole, bisphenol S, 1, 4 Add naphthoquinone and sodium carbonate to a three-necked flask connected to a water separator, then add N,N-dimethylformamide and toluene, stir and react at 127°C for 3.5 hours in a helium atmosphere, and remove through the water separator For the water and toluene generated during the reaction, after removing all the water, slowly raise the reaction temperature to 143°C, continue to stir and reac...

Embodiment 3

[0042] An environmentally friendly waterproof material, characterized in that it is prepared from the following raw materials in parts by weight: 40 parts of 3,6-dibromo-9-vinylcarbazole / bisphenol S polycondensate, vinyl-terminated polyurethane 17 parts of polymer modified coal tar pitch, 13 parts of vinyl-terminated nitrile rubber, 4.5 parts of hyperbranched polysiloxane, and 0.085 parts of azobisisobutyronitrile.

[0043] The preparation method of the 3,6-dibromo-9-vinylcarbazole / bisphenol S polycondensate comprises the following steps: 3,6-dibromo-9-vinylcarbazole, bisphenol S, 1, 4 Add naphthoquinone and potassium carbonate to a three-necked flask connected to a water separator, then add N,N-dimethylacetamide and toluene, stir and react at 130°C for 4 hours in a neon atmosphere, and remove through the water separator The water and toluene generated during the reaction, after removing all the water, slowly raise the reaction temperature to 145°C, continue stirring for 9 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com