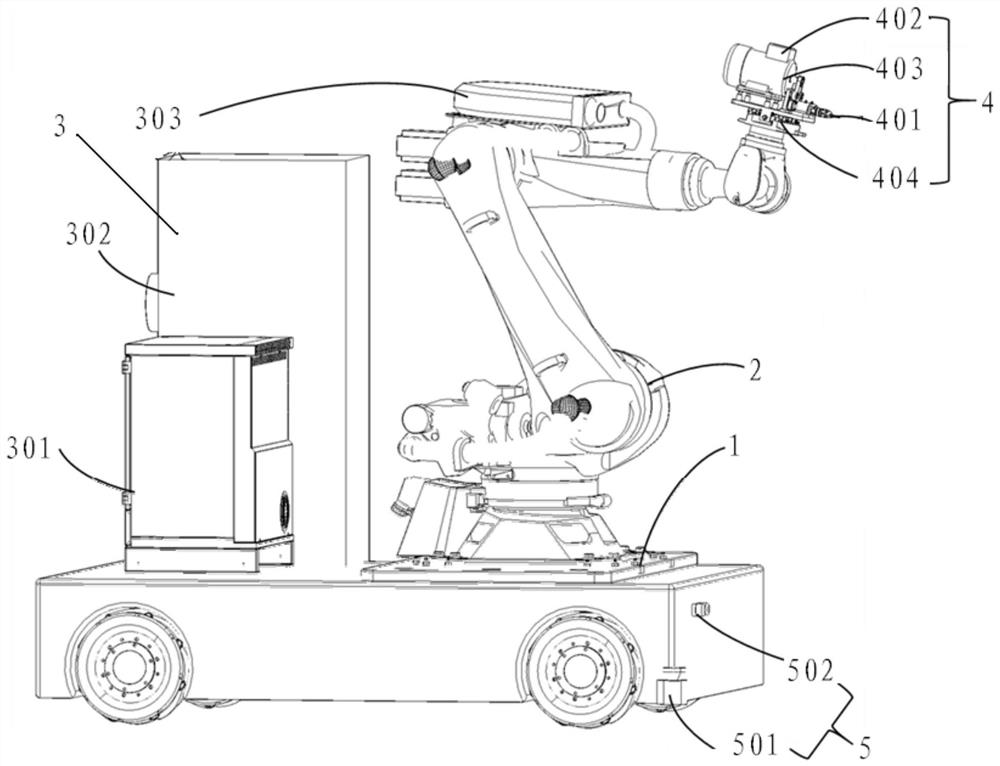

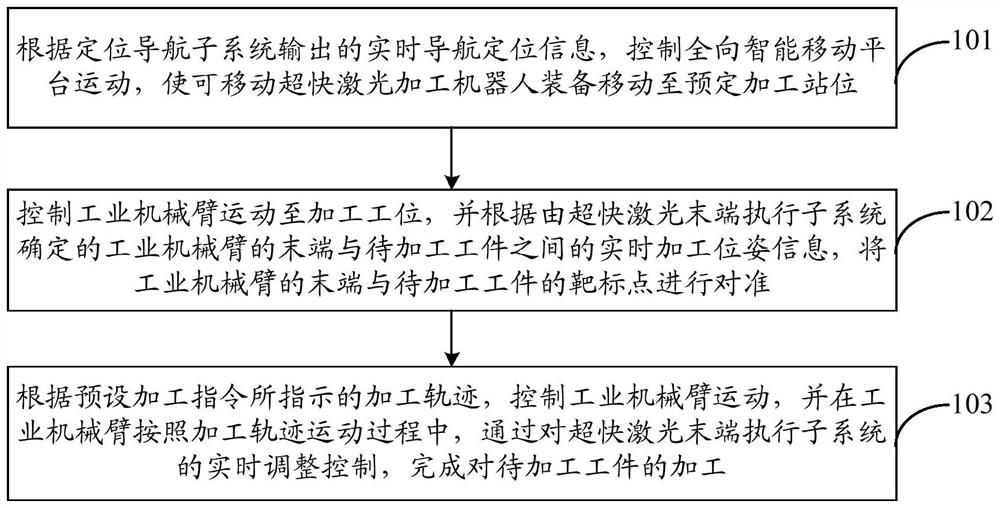

A mobile ultrafast laser processing robot equipment and processing method

An ultra-fast laser and robot technology, used in laser welding equipment, metal processing equipment, manipulators, etc., can solve the problems of frequent tool changes, poor accuracy consistency, low processing efficiency, etc., to achieve laser cold processing, reduce pulse broadening, The effect of expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0053] In order to solve the processing needs of many large-scale non-metallic composite materials (resin-based composite materials, ceramic-based composite materials, carbon-based composite materials, etc.) Tear, difficult preparation of tiny structures, inability to process large-scale structures, low processing efficiency and other outstanding common problems in terms of quality, precision, efficiency, and machinable objects, etc., the present invention can integrate "mobile robots" and "high-performance industrial On the basis of the first-class ultrafast laser, a mobile ultrafast laser processing robot equipment will be formed to realize large-scale flexible attitude adjustment, positioning and local high-efficiency and high-qualit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com