A method for preparing large-sized grain perovskite thin films by scraping method

A perovskite, large-scale technology, which is applied in the field of preparing large-scale grain perovskite thin films by the blade coating method, can solve the problems of slowness, high toxicity, high consumption, etc., and achieves simple equipment structure, low equipment cost, and simplicity. The effect of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

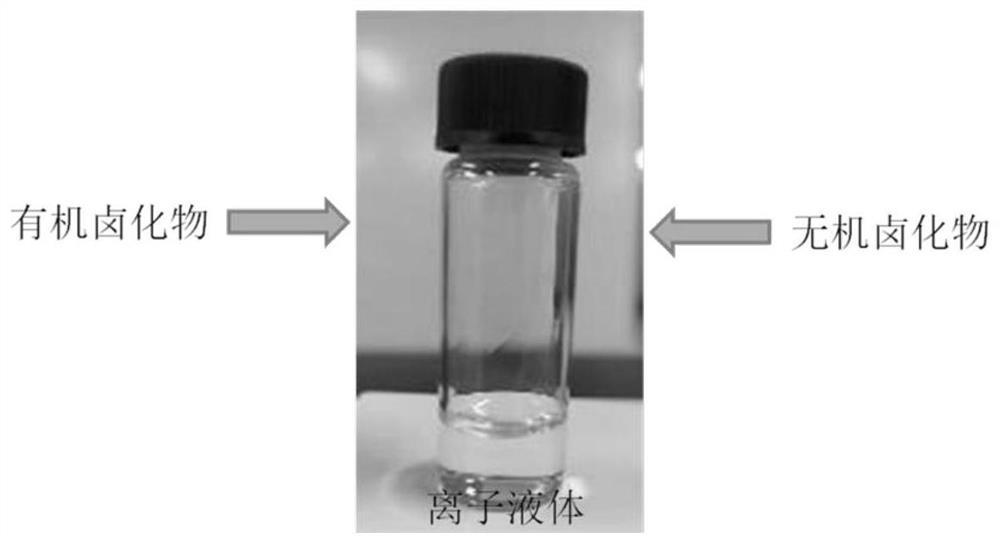

[0043] Preparation of Ionic Liquid Perovskite Scratch Coating Precursor:

[0044] like figure 1 As shown, the inorganic halide (YX 2 ) and organic halides (MAI or MAI and FAI) were added to the protic ionic liquid at a molar ratio of 1:1. Ionic liquids are used as solvents for perovskite precursors. In an inert gas atmosphere, heat at 55° C. and stir for 6-9 hours, and then transfer the perovskite precursor solution to the air environment for scraping to prepare a perovskite film. The active ingredient of the protic ionic liquid is one or several mixtures of MAAc (methylamine acetate), MAP (methylamine propionate) and MABa (methylamine butyrate).

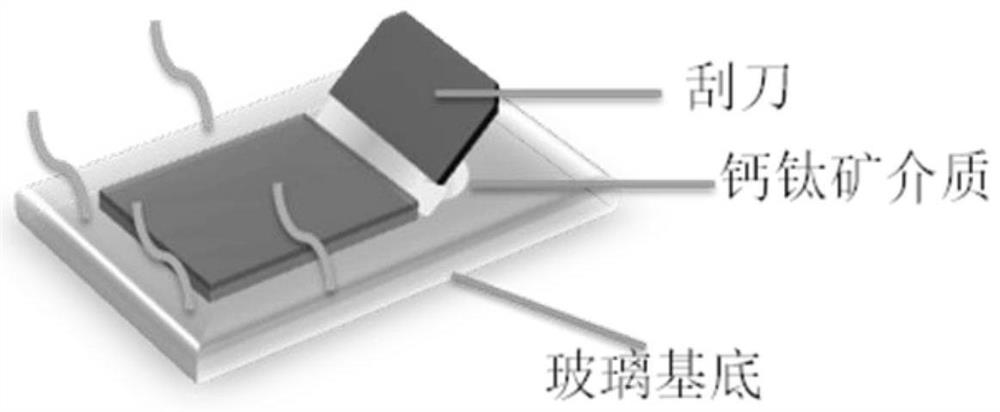

[0045] Preparation of perovskite thin films by doctor blade method:

[0046] First, the FTO (fluorine-doped tin dioxide)-coated glass substrate was cleaned with lye, active detergent, deionized water, and ethanol. The FTO-coated glass was ultrasonically cleaned sequentially in lye, active detergent, deionized water, and ethano...

Embodiment 1

[0051] This embodiment provides a method for preparing a perovskite film by blade coating, the specific steps are as follows:

[0052] Step 1: MAI (methylamine hydroiodide) and PbI with a molar ratio of 1:1 2 (lead iodide) mixed with 1mL ionic liquid MAAc, MAI and PbI 2 The masses were 102 mg and 298 mg respectively, and they were stirred for 9 hours under heating at 55° C. before use.

[0053] Step 2: Spin c-TiO 2 The substrate was preheated at 100°C for 5 minutes, and the distance between the coating scraper and the substrate was adjusted to 0.1 mm, and then 10 μL of the perovskite precursor solution was transferred to the slit between the scraper and the substrate with a pipette gun. .

[0054] Step 3: Drag the scraper at a speed of 30mm / s to obtain a wet perovskite film, and the wet film will gradually turn black and undergo a phase transition. After scrape coating, anneal for 20 seconds on a scraper coater, and then transfer the phase-transformed perovskite film to a ...

Embodiment 2

[0057] This embodiment provides a method for preparing a perovskite film by blade coating, the specific steps are as follows:

[0058] Step 1: MAI, FAI and PbI with a molar ratio of 0.5:0.5:1 2 Mix with 1 mL of ionic liquid MAAc, MAI, FAI and PbI 2 The masses are 50.8mg, 54.9mg, and 294.3mg respectively, and they are heated at 55°C and stirred for 9 hours before use.

[0059] Step 2: Spin c-TiO 2 The substrate was preheated at 100°C for 5 minutes, and the distance between the coating scraper and the substrate was adjusted to 0.1 mm, and then 10 μL of the perovskite precursor solution was transferred to the slit between the scraper and the substrate with a pipette gun. .

[0060] Step 3: Drag the scraper at a speed of 30mm / s to obtain a wet perovskite film, and the wet film will gradually turn black and undergo a phase transition. After the blade coating, anneal on the blade coater for 20 seconds, then transfer the phase-transformed perovskite film to a hot stage at 110°C a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com