Molecular brush polymer film based on cellulose network structure, and preparation method and application thereof

A technology of polymer film and network structure, applied in final product manufacturing, sustainable manufacturing/processing, electrolyte battery manufacturing, etc. Effects of Li dendrite growth, increasing ionic conductivity and increasing migration number

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

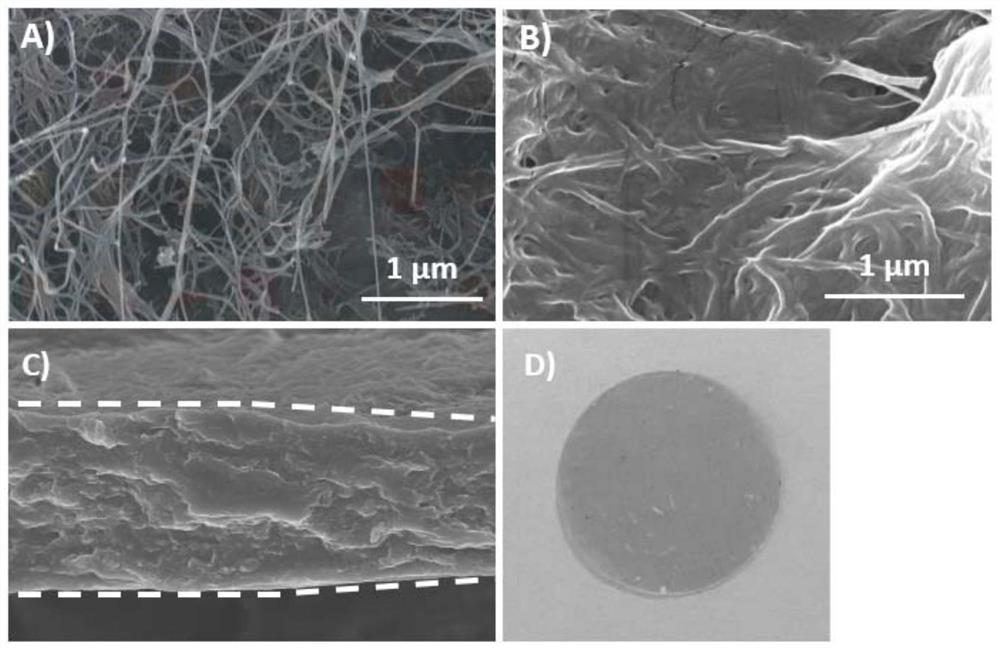

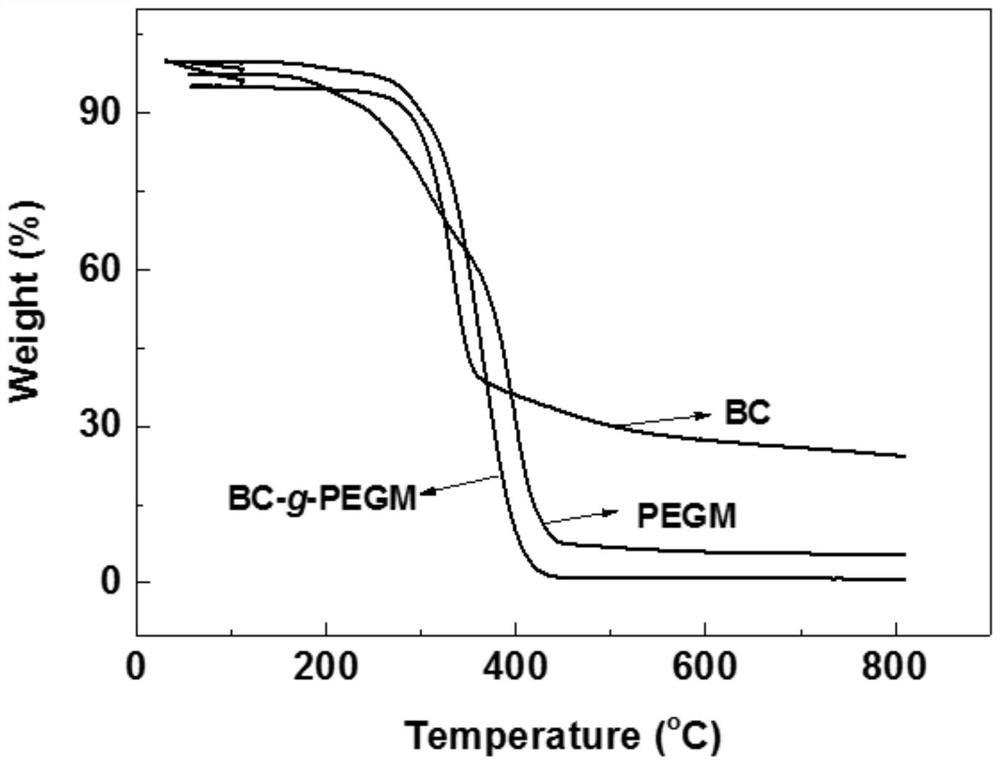

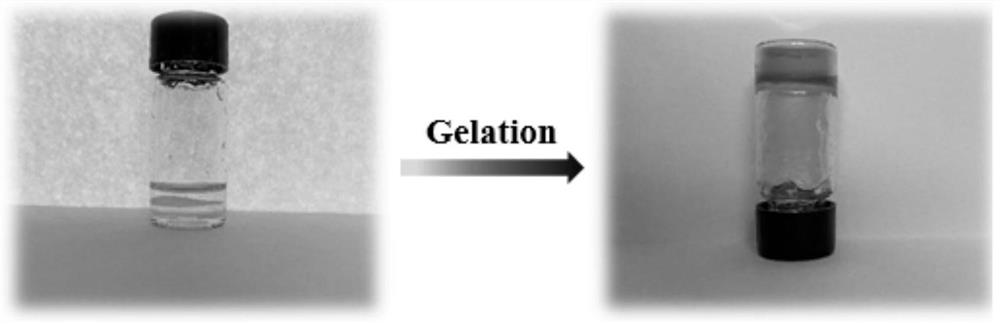

[0052] The embodiment of the present invention provides a preparation of a cellulose functional molecular brush gel polymer material with a three-dimensional network structure and its application in the preparation of lithium metal batteries, including the following steps:

[0053] (1) Remove the water in the bacterial cellulose dispersion and replace it with N,N-dimethylformamide: first, centrifuge the aqueous dispersion containing 500 mg bacterial cellulose for 30 minutes to remove most of the water solvent, and then uniformly disperse it in 200 mL N , in a mixed solution of N-dimethylformamide and 100mL cyclohexane, under the protection of nitrogen, heat and distill in an oil bath at 105°C for 8h, and after anhydrous distillation, reduce the temperature of the oil bath to 90°C, The cyclohexane was distilled off, and all the water was replaced with N,N-dimethylformamide.

[0054] (2) The bacterial cellulose (BC) obtained in step (1) is modified and connected with bromine gro...

Embodiment 2

[0066] The embodiment of the present invention provides a preparation of a cellulose functional molecular brush gel polymer material with a three-dimensional network structure and its application in the preparation of lithium metal batteries, including the following steps:

[0067] (1) Remove the water in the bacterial cellulose dispersion and replace it with N,N-dimethylformamide: first, centrifuge the aqueous dispersion containing 500 mg bacterial cellulose for 30 minutes to remove most of the water solvent, and then uniformly disperse it in 200 mL N , in a mixed solution of N-dimethylformamide and 100mL cyclohexane, under the protection of nitrogen, heat and distill in an oil bath at 105°C for 8h, and after anhydrous distillation, reduce the temperature of the oil bath to 90°C, The cyclohexane was distilled off, and all the water was replaced with N,N-dimethylformamide.

[0068](2) The bacterial cellulose (BC) obtained in step (1) is modified and connected with bromine grou...

Embodiment 3

[0074] The embodiment of the present invention provides a preparation of a cellulose functional molecular brush gel polymer material with a three-dimensional network structure and its application in the preparation of lithium metal batteries, including the following steps:

[0075] (1) Remove the water in the bacterial cellulose dispersion and replace it with N,N-dimethylformamide: first, centrifuge the aqueous dispersion containing 500 mg bacterial cellulose for 30 minutes to remove most of the water solvent, and then uniformly disperse it in 200 mL N , in a mixed solution of N-dimethylformamide and 100mL cyclohexane, under the protection of nitrogen, heat and distill in an oil bath at 105°C for 8h, and after anhydrous distillation, reduce the temperature of the oil bath to 90°C, The cyclohexane was distilled off, and all the water was replaced with N,N-dimethylformamide.

[0076] (2) The bacterial cellulose (BC) obtained in step (1) is modified and connected with bromine gro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com