A kind of salt inhibitor for back-spraying quench tower process of salty wastewater

A technology for salt-containing wastewater and quenching towers, applied in the field of salt blocking agents, can solve problems such as hidden safety hazards, health effects of operators, and effects on the normal operation of devices, and achieve the effect of reducing the difficulty of cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

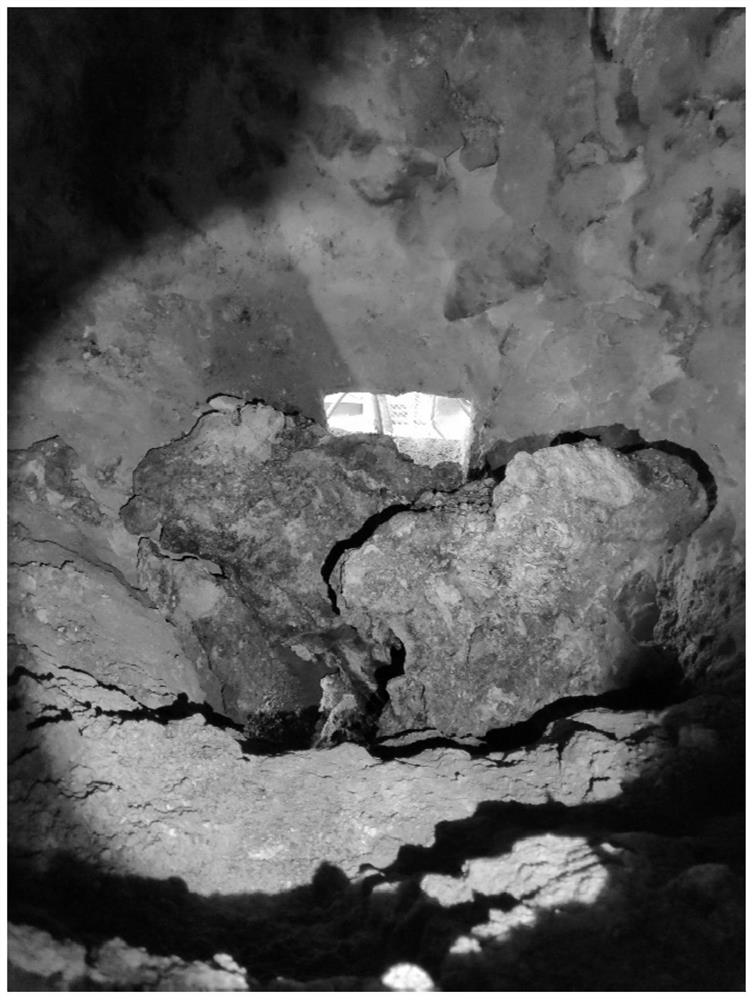

[0046] At the site of a hazardous waste incineration enterprise in Jiangsu, a single rotary kiln incinerator burns 70 tons of industrial solid waste and industrial hazardous waste every day, and produces about 75 tons of wastewater with a salt content of 3-8wt% per day. Before the salt inhibitor is added, the salty wastewater is sprayed back into the quench tower, and the slag port of the quench tower falls, and the falling fly ash is about 2 tons per day; the salt accumulation in the tower is serious, every 20 days or so, the flue gas of the quench tower More than half of the channel is blocked, and the negative pressure cannot be pulled, so it must be stopped for manual cleaning; during the cleaning process, it is found that the accumulated salt is very hard, like a rock (such as figure 1 shown). It is necessary to use an air pick to slowly remove the salt accumulated on the tower wall, and the cleaning cycle can be as long as 5 to 7 days.

[0047] Dissolve potassium ferroc...

Embodiment 2

[0051] In the same part of the same system at the user site of Example 1, add a salt blocking agent composed of potassium ferrocyanide and polyacrylic acid (number average molecular weight is about 1060, molecular weight distribution index 2.13), according to the mass ratio of 1:10 (At the same time, ascorbic acid or erythorbic acid in the same proportion as potassium ferrocyanide is added as an antioxidant to ensure the stability of potassium ferrocyanide). Dissolve polyacrylic acid and ascorbic acid in deionized water and mix until completely dissolved, adjust the pH value to about 10 with alkali, then add potassium ferrocyanide, mix evenly until completely dissolved, and prepare an aqueous solution of salt inhibitor, among which, ferrous The potassium cyanide concentration is about 2 wt %, and the polyacrylic acid concentration is about 20 wt %. Add the aqueous solution of salt blocking agent to the brine pipeline before entering the quench water tank, install a pipeline mi...

Embodiment 3

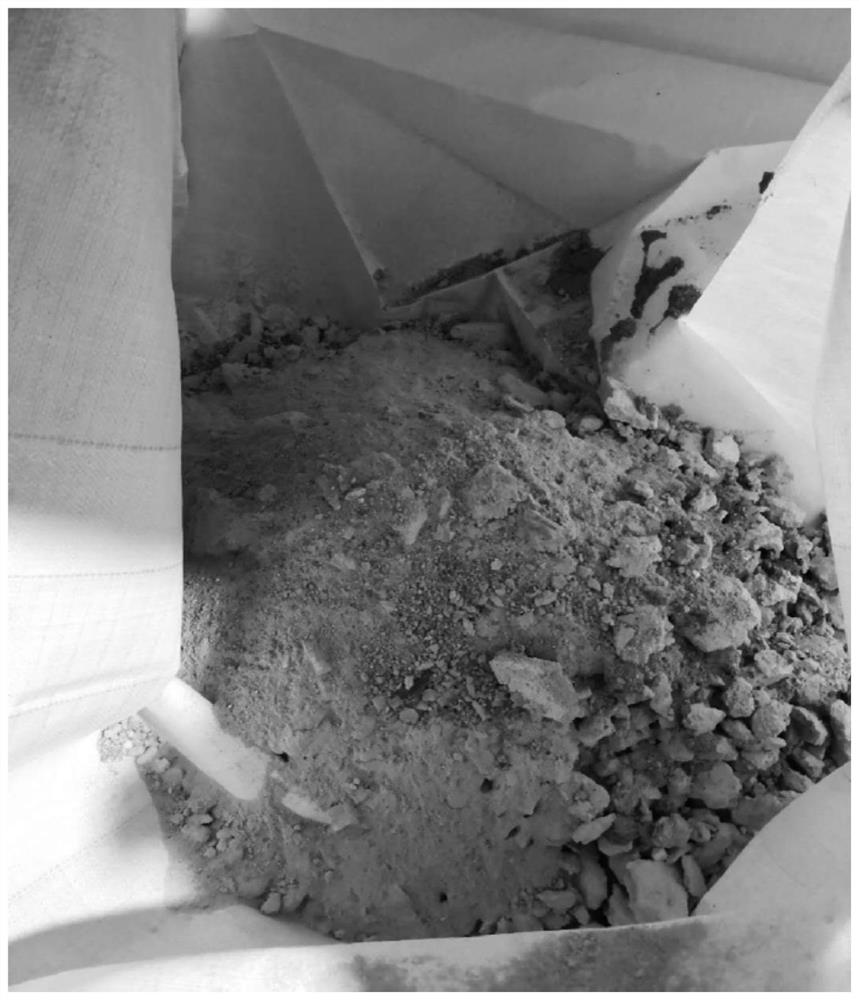

[0055] In another industrial hazardous waste incineration site in Jiangsu, the third phase of a single rotary kiln has a daily incineration capacity of 50 tons, and produces about 45-60 tons of saline wastewater with a salt content of about 8wt% every day. tower. Before the salt inhibitor was added, the negative pressure of the quenching tower could not be pulled every 7 days of operation, and it was necessary to keep the cooling tower clean for 24 hours without stopping, and the production load was seriously insufficient. Figure 5 shown). The work intensity is large, the cleaning area is not enough, the residual salt is very large, and the water dripping under the quenching tower is serious.

[0056] Install a pipeline mixer on the brine pipeline before the quench water tank, and add potassium ferrocyanide and hydrolyzed polymaleic anhydride (number average molecular weight about 410, molecular weight distribution index 1.21), A salt inhibitor composed of a mass ratio of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com