A kind of preparation method of low-phenylalanine egg white protein peptide

A technology of low-phenylalanine eggs and phenylalanine eggs, which is applied in the food field, can solve technical difficulties and other problems, and achieve the effects of improving enzymatic hydrolysis, improving the utilization rate of adsorbents, and reducing the molecular weight of polypeptides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

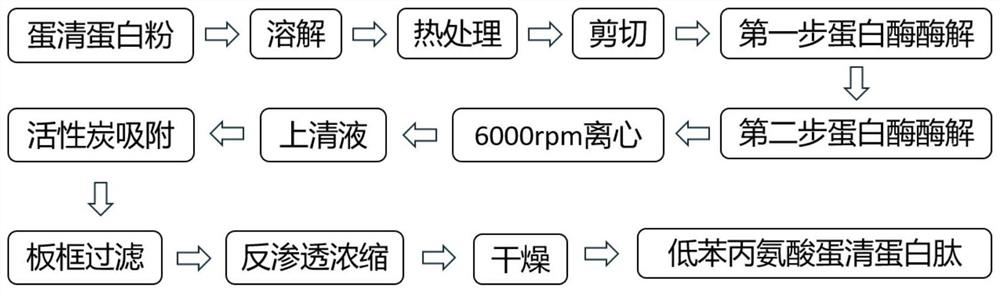

[0064] A method for preparing low-phenylalanine egg white protein peptides, comprising the following steps:

[0065] (1) Dissolution, heat treatment and shear treatment of egg white protein powder

[0066] Dissolve 750g egg white protein powder (the protein content is 80.23% as measured by Kjeldahl, and phenylalanine accounts for 6.08% of the total protein as measured by the amino acid analyzer) in water until the protein concentration is 24g / L. Heating and stirring at low temperature for 15 minutes to carry out thermal denaturation treatment of protein, and then shearing at 11000 rpm for 2 minutes by a high-speed disperser to obtain a pretreatment solution;

[0067] (2) Two-step protease treatment

[0068] Adjust the pH of the pretreatment solution to 8.0, heat to 37°C, add trypsin at 8g / 100g protein, and enzymolyze it for 7 hours to obtain a trypsin enzymolysis solution; adjust the pH of the trypsin enzymolysis solution to 7.0, heat to 50°C, Add flavor protease at the rate...

Embodiment 2

[0083] A method for preparing low-phenylalanine egg white protein peptides, comprising the following steps:

[0084] (1) Dissolution, heat treatment and shear treatment of egg white protein powder

[0085] 1kg of egg white protein powder (the protein content measured by the Kjeldahl method is 80.23%, and the amino acid analyzer shows that phenylalanine accounts for 6.08% of the total protein) is dissolved in water until the protein concentration is 32g / L, and the sandwich pot is used at 100 Heat and stir at ℃ for 15 minutes to carry out thermal denaturation treatment of protein, and then shear at 11,000 rpm for 3 minutes through a high-speed disperser to obtain a pretreatment solution;

[0086] (2) Two-step protease treatment

[0087] Adjust the pH of the pretreatment solution to 8.0, heat to 37°C, add trypsin at a rate of 9g / 100g protein, and enzymatically hydrolyze for 6 hours to obtain a trypsin enzymolysis solution; adjust the pH of the trypsin enzymolysis solution to 7.0...

Embodiment 3

[0097] Embodiment 3: the influence of trypsin addition amount

[0098] Refer to the protease hydrolysis of step (2) in Example 1: add different amounts of trypsin for enzymolysis, other conditions are the same as in Example 1, and the obtained data are shown in Table 3;

[0099] Table 3 Effects of different amounts of trypsin added on the degree of hydrolysis, peptide yield and product phenylalanine content

[0100]

[0101] Note: The degree of hydrolysis refers to the degree of hydrolysis of the double-enzyme hydrolyzate obtained by two-step enzymatic hydrolysis with trypsin and flavor protease; the peptide yield refers to the ratio of the final low-phenylalanine polypeptide powder to the total protein content of the raw material; the final phenylalanine peptide powder Alanine content refers to the ratio of phenylalanine to protein equivalents in the final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com