A cement slurry with large temperature difference and low thermal conductivity suitable for well cementing in long sealing intervals

A technology that conducts hot water and has a large temperature difference. It is applied in solid waste management, drilling composition, sustainable waste treatment, etc. It can solve the problems of low strength of top cement stone, large heat loss due to oil and gas migration, and thermal conductivity of annular cement stone. Large and other problems, to achieve the effect of improving interlayer isolation ability, avoiding volume shrinkage, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

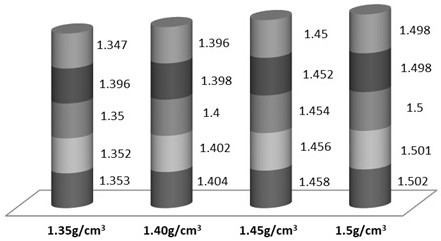

Image

Examples

Embodiment 1

[0040] The density is 1.50g / cm 3 The lightening agent (microsphere) adopts the hollow glass microsphere produced by Sinosteel Maanshan Mining Institute New Material Technology Co., Ltd.

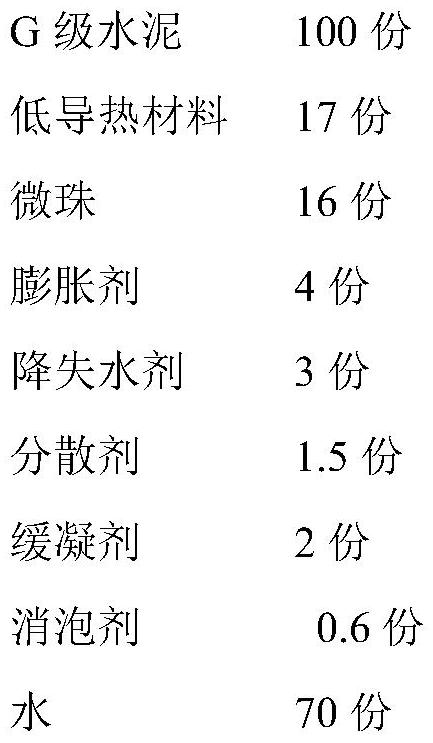

[0041]

[0042] All of the above are measured in quality units;

[0043] Wherein, the density of the low-density cement slurry is 1.40g / cm 3 , the temperature is 100°C, and the pressure bearing capacity is 50MPa;

[0044] The low thermal conductivity material is composed of the following components in parts by weight: 0.75 parts of microsilicon, 0.08 parts of perlite, 0.08 parts of diatomite, 0.06 parts of bentonite, 0.10 parts of fiber powder, and 0.04 parts of tungsten diselenide;

[0045] The microspheres are high-strength glass microspheres, and the true density of the high-strength glass microspheres is 0.60g / cm 3 , the particle size is 3.55-111um, the median particle size Dv(50) is 28μm, and Dv(90) is 51.3μm;

[0046] The expansion agent is composed of sodium chloride: sodium thi...

Embodiment 2

[0052] The density is 1.45g / cm 3 The lightening agent (microsphere) adopts the hollow glass microsphere produced by Sinosteel Maanshan Mining Institute New Material Technology Co., Ltd.

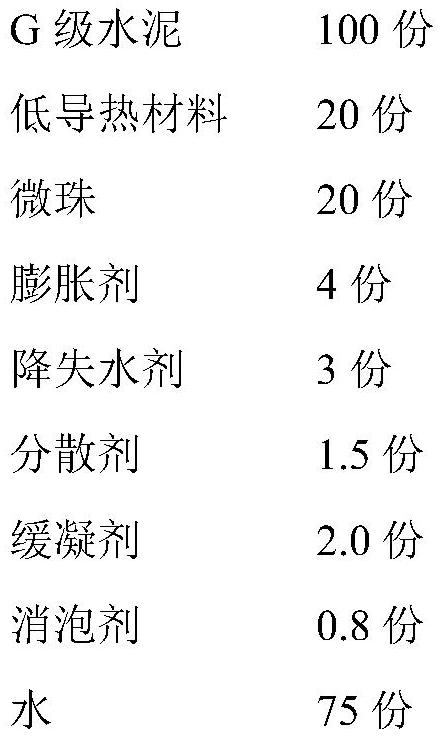

[0053]

[0054] All of the above are measured in quality units;

[0055] Wherein, the density of the low-density cement slurry is 1.35g / cm 3 , the temperature is 120°C, and the pressure bearing capacity is 60MPa;

[0056] The low thermal conductivity material is composed of the following components in parts by weight: 0.70 parts of microsilicon, 0.10 parts of perlite, 0.05 parts of diatomaceous earth, 0.08 parts of bentonite, 0.12 parts of fiber powder, and 0.04 parts of tungsten diselenide;

[0057] The microspheres are high-strength glass microspheres, and the true density of the high-strength glass microspheres is 0.55g / cm 3 , the particle size is 3.55-111um, the median particle size Dv(50) is 28μm, and Dv(90) is 51.3μm;

[0058] The expansion agent is composed of sodium chloride: s...

Embodiment 3

[0064] The density is 1.40g / cm 3 The lightening agent (microsphere) adopts the hollow glass microsphere produced by Sinosteel Maanshan Mining Institute New Material Technology Co., Ltd.

[0065]

[0066] All of the above are measured in quality units;

[0067] Wherein, the density of the low-density cement slurry is 1.50g / cm 3 , the temperature is 60°C, and the pressure bearing capacity is 80MPa;

[0068] The low thermal conductivity material is composed of the following components in parts by weight: 0.85 parts of microsilicon, 0.03 parts of perlite, 0.06 parts of diatomite, 0.09 parts of bentonite, 0.15 parts of fiber powder, and 0.03 parts of tungsten diselenide;

[0069] The microspheres are high-strength glass microspheres, and the true density of the high-strength glass microspheres is 0.55-0.65g / cm 3 , the particle size is 3.55-111um, the median particle size Dv(50) is 28μm, and Dv(90) is 51.3μm;

[0070] The expansion agent is composed of sodium chloride: sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| bearing capacity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com