Hydrophilic hyperbranched polyglycidyl ether anion magnetic adsorbent as well as preparation method and application thereof

A technology of polyglycidyl ether and glycidyl ether, which is applied in chemical instruments and methods, ion exchange, selective adsorption, etc., can solve the problems of poor hydrophilicity, limited number of functional groups, and low adsorption capacity of cochineal to achieve high-efficiency adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A preparation method of hydrophilic hyperbranched polyglycidyl ether anion magnetic adsorbent, comprising the following steps:

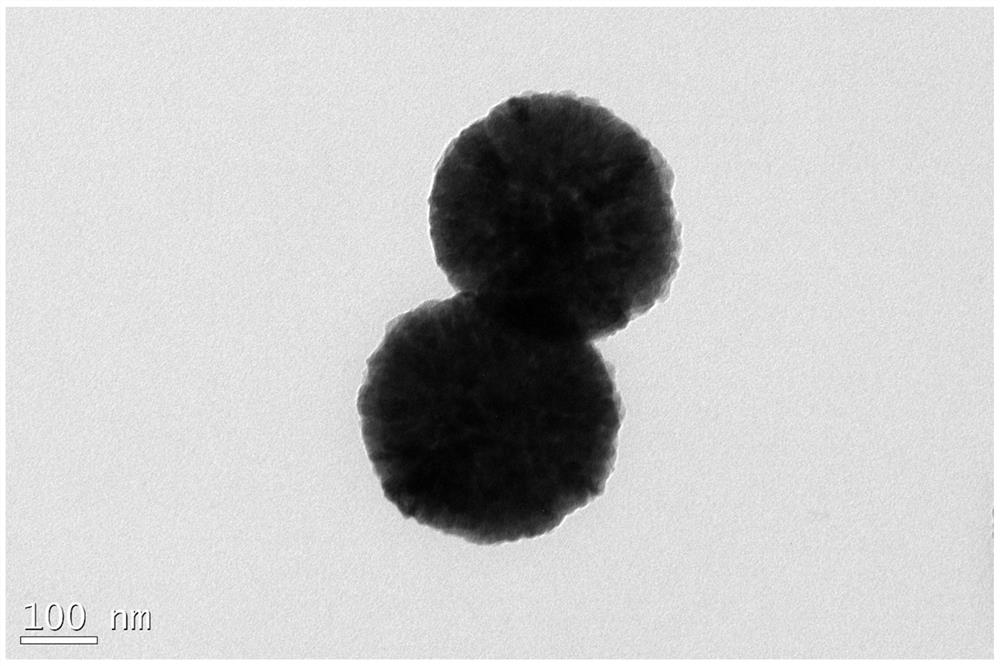

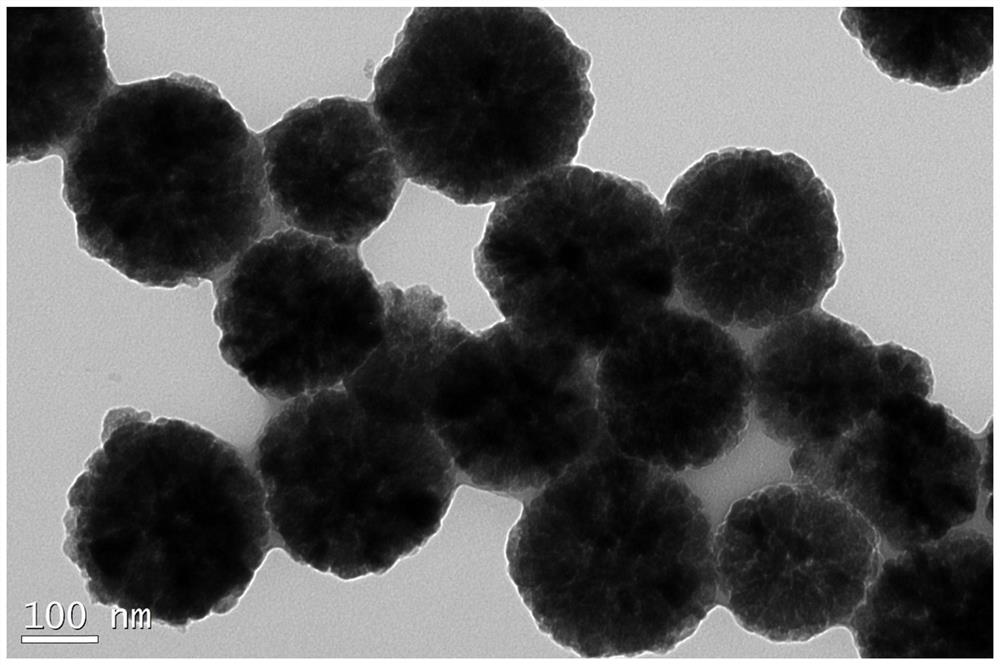

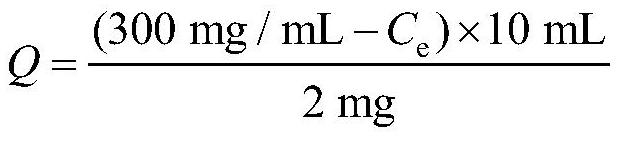

[0028] Step 1. Put 2.0g of ferric chloride, 4.0g of anhydrous sodium acetate and 35mL of ethylene glycol in a reaction kettle, and react at 160°C for 8h. Under the condition of vacuum drying for 6h, the magnetic nanospheres were prepared. Such as figure 1 As shown, the particle size of the prepared magnetic nanosphere is about 350nm.

[0029] Step 2. Put 50mg of magnetic nanospheres, 25μL of potassium methoxide and 1mL of anhydrous tetrahydrofuran into a 100mL three-neck flask, under nitrogen protection, stir at 30°C for 1h, raise the temperature to 80°C, and shrink 1.5mL by a peristaltic pump device. The glycerol ether monomer was slowly added dropwise into the three-necked flask, and the dropping time was 10 hours. After the addition of the monomer was completed, the product was separated by an external magnetic field, washed, and dried i...

Embodiment 2

[0039] A preparation method of hydrophilic hyperbranched polyglycidyl ether anion magnetic adsorbent, comprising the following steps:

[0040]Step 1. Put 3.0g of ferric chloride, 5.0g of anhydrous sodium acetate and 40mL of ethylene glycol in a reaction kettle, and react at 200°C for 10h. Under the condition of vacuum drying for 8h, the magnetic nanospheres were obtained;

[0041] Step 2. Put 100mg of magnetic nanospheres, 28μL of potassium methoxide and 2.0mL of anhydrous tetrahydrofuran into a 100mL three-neck flask, under nitrogen protection, stir at 50°C for 2h, raise the temperature to 95°C, and pump 2.0mL of The glycidyl ether monomer was slowly added dropwise into the three-necked flask for 12 hours. After the addition of the monomer is completed, the product is separated by an external magnetic field, washed, and vacuum-dried at 30°C and 0.02MPa for 8 hours to prepare a hydrophilic hyperbranched polyglycidyl ether anionic magnetic adsorbent;

[0042] The hydrophilic ...

Embodiment 3

[0051] A preparation method of hydrophilic hyperbranched polyglycidyl ether anion magnetic adsorbent, comprising the following steps:

[0052] Step 1. Put 5.0g of ferric chloride, 6.0g of anhydrous sodium acetate and 55mL of ethylene glycol in a reaction kettle, and react at 230°C for 12h. Under the condition of vacuum drying for 9 hours, the magnetic nanospheres were obtained;

[0053] Step 2: Put 150 mg of magnetic nanospheres, 30 μL of potassium methoxide and 3.0 mL of anhydrous tetrahydrofuran into a 100 mL three-necked flask, and stir at 53°C for 3 hours under nitrogen protection, raise the temperature to 100°C, and pump 3.0mL of The glycidyl ether monomer was slowly added dropwise into the three-necked flask for 15 hours. After the addition of the monomer is completed, the product is separated by an external magnetic field, washed, and vacuum-dried at 40°C and 0.04MPa for 9 hours to prepare a hydrophilic hyperbranched polyglycidyl ether anionic magnetic adsorbent;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com