Carbon nitride quantum dot/tungsten trioxide composite photocatalytic material and preparation method thereof

A technology of composite photocatalysis and tungsten trioxide, which is applied in the direction of catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, etc., can solve complex preparation methods, easy aggregation of quantum dots, and problems that have not yet been solved. See the problems of tungsten trioxide composite photocatalytic materials, etc., to achieve the effect of expanding the photoresponse range, improving the separation efficiency, and reducing the probability of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

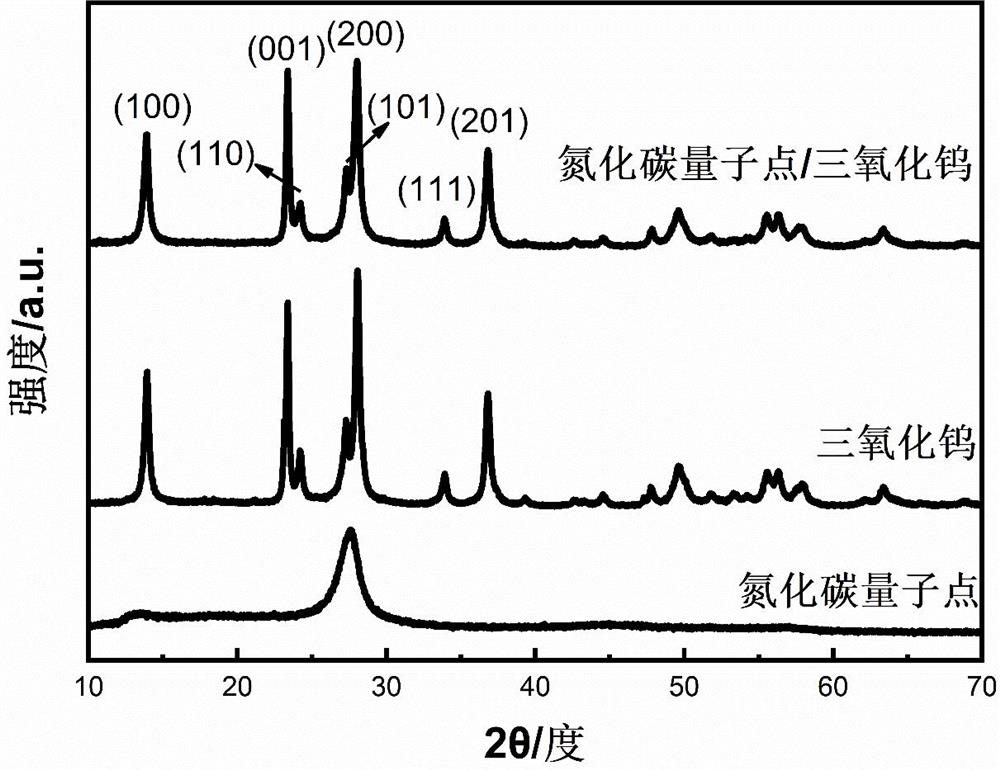

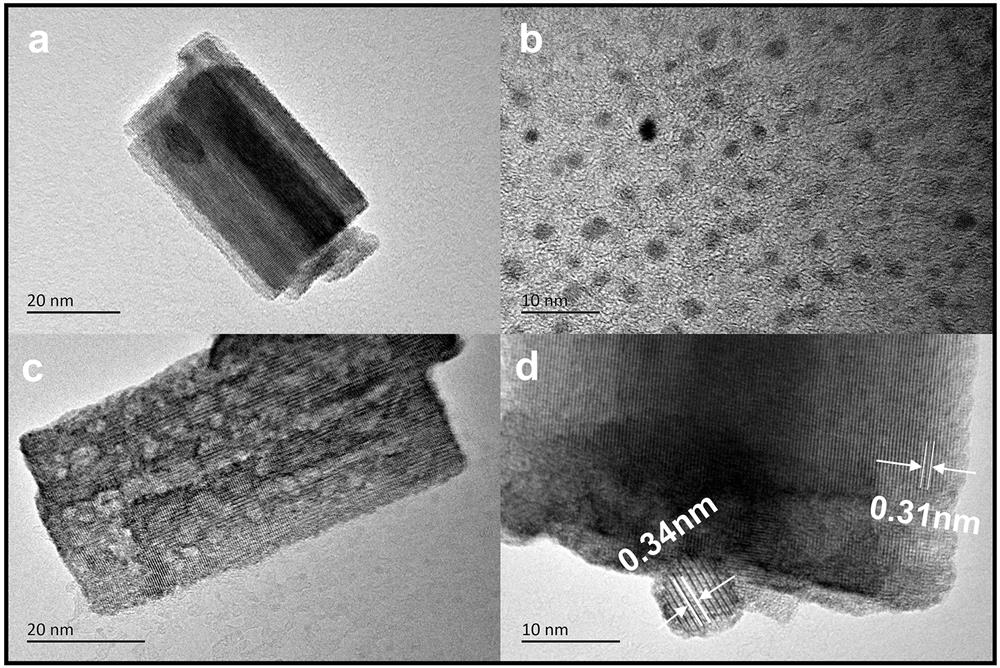

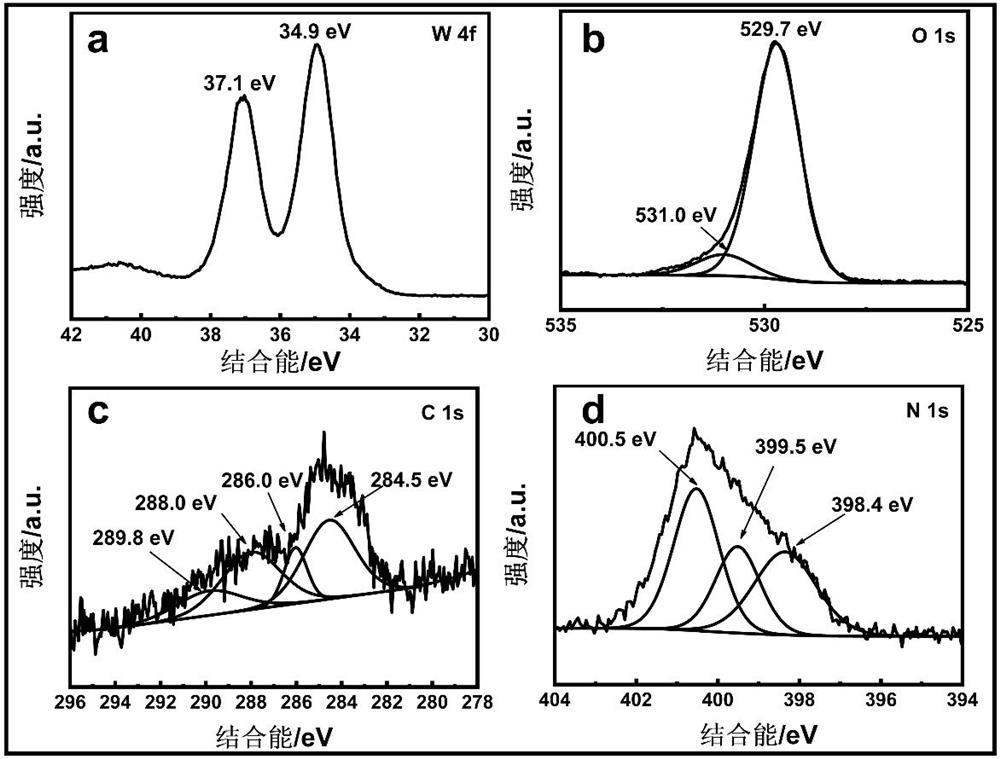

[0029] The invention provides a carbon nitride quantum dot / tungsten trioxide composite photocatalytic material and a preparation method thereof. The carbon nitride quantum dot / tungsten trioxide composite photocatalytic material is formed by loading carbon nitride quantum dots on the surface of tungsten trioxide The dense heterojunction structure, its preparation method comprises the following steps:

[0030] (1) Preparation of carbon nitride quantum dots: Weigh a certain molar ratio of sodium citrate and urea, dissolve in deionized water after grinding, ultrasonically disperse, transfer to a hydrothermal kettle for reaction, the reaction temperature is 160-200°C, and the reaction The time is 0.5-4h, then cooled and filtered through a 0.22μm microfiltration membrane, dialyzed for 12-48h, and freeze-dried to obtain carbon nitride quantum dots;

[0031] Wherein, the molar ratio of sodium citrate and urea is 2-8:1.

[0032] (2) Preparation of tungsten trioxide nanorods: Weigh a c...

Embodiment 1

[0040] Weigh 1.01g of sodium citrate and 0.81g of urea, grind for 30 minutes, dissolve in 60mL of deionized water, ultrasonically disperse, transfer to a hydrothermal kettle, react at 180°C for 2h, cool and filter through a 0.22μm microfiltration membrane, and dialyze for 24h , to obtain carbon nitride quantum dots after freeze-drying.

[0041] Weigh 3.5g of ammonium metatungstate, grind it and dissolve it in 50mL of deionized water. After ultrasonic dispersion, add a certain amount of acid to adjust the pH of the solution to 2. Transfer it to a hydrothermal kettle for 24 hours at 180°C. After cooling, wash with water and alcohol Wash each 3 times and dry at 60°C to obtain tungsten trioxide nanorods.

[0042] Weigh 0.05g of carbon nitride quantum dots into 100mL of deionized water, add 1g of tungsten trioxide nanorods, stir for 30min, ultrasonically disperse, place in a hydrothermal kettle for 2h at 120°C, cool, and freeze-dry the sample at 50°C After vacuum drying, the carbo...

Embodiment 2

[0045] Weigh 1.01g of sodium citrate and 0.81g of urea, grind for 30 minutes, dissolve in 60mL of deionized water, ultrasonically disperse, transfer to a hydrothermal kettle, react at 180°C for 2h, cool and filter through a 0.22μm microfiltration membrane, and dialyze for 24h , to obtain carbon nitride quantum dots after freeze-drying.

[0046] Weigh 3.5g of ammonium metatungstate, grind it and dissolve it in 50mL of deionized water. After ultrasonic dispersion, add a certain amount of acid to adjust the pH of the solution to 2. Transfer it to a hydrothermal kettle for 24 hours at 180°C. After cooling, wash with water and alcohol Wash each 3 times and dry at 60°C to obtain tungsten trioxide nanorods.

[0047] Weigh 0.05g of carbon nitride quantum dots into 100mL of deionized water, add 1g of tungsten trioxide nanorods, stir for 30min, ultrasonically disperse, place in a hydrothermal kettle for 2h at 120°C, cool, and freeze-dry the sample at 50°C After vacuum drying, the carbo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com