Direct reduction metallurgy method for iron ore based on 3D printing

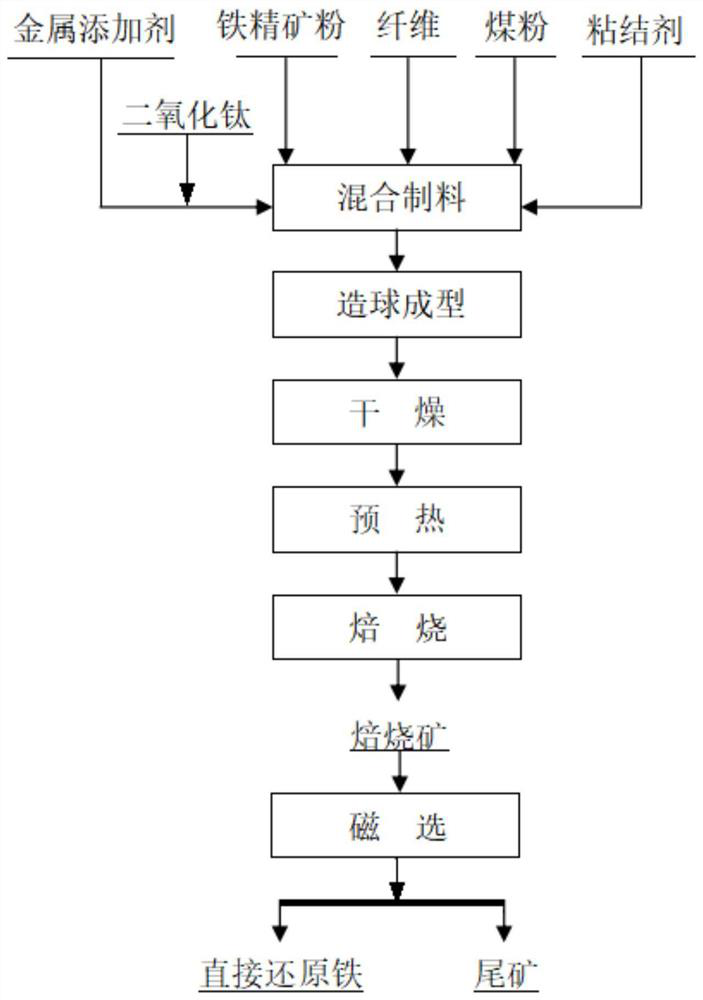

A 3D printing and direct technology, applied in the field of direct reduction metallurgy of iron ore based on 3D printing, and the field of direct reduction iron preparation by 3D printing, which can solve the problems of high reaction temperature, easy generation of powder and long time, and reduce the reaction temperature and time. , The effect of sufficient gas-solid contact and increased specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100]1) Proportionally measure 120 parts of hematite powder from Brazil, 3 parts of bentonite from India, 0.12 parts of nanometer titanium dioxide, 0.12 parts of micrometer vanadium pentoxide, 0.08 parts of micrometer cerium oxide, and 24 parts of coal powder. Stir and mix uniformly, add 0.6 parts of high elastic modulus polyethylene fiber in batches 3 times during the stirring process to obtain the final 3D printing mixture.

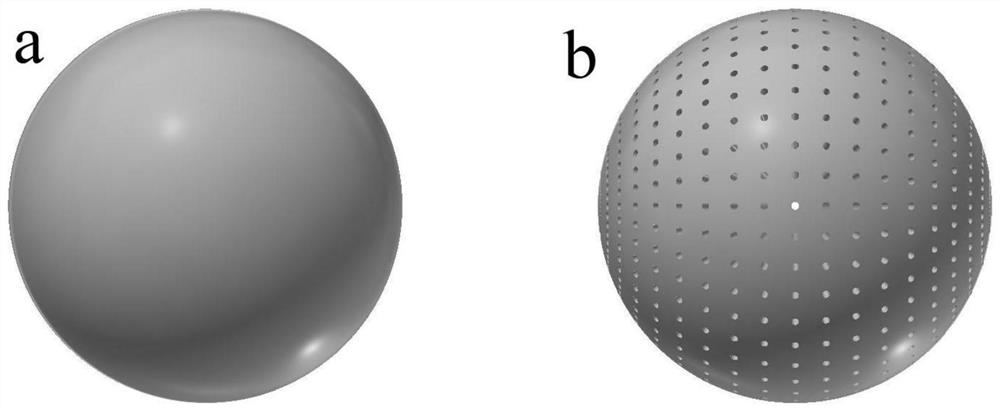

[0101]2) Then use the 3D printing equipment to print the above 3D printing mixture in batches according to the preset programming procedure to obtain honeycomb pellets with a particle size of 10mm, and then place the honeycomb pellets in an oven at 105°C for 3 hours. .

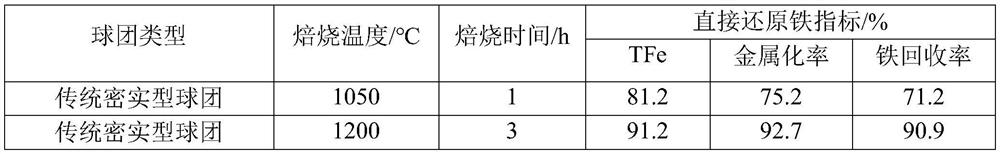

[0102]3) Then put the above-mentioned dried honeycomb pellets in a muffle furnace at 600°C for 15min, then heat the muffle furnace to 1050°C for roasting for 1h, then use cold water to cool directly to obtain roasted ore .

[0103]4) Finally, the roasted ore is crushed and ground and then subjected t...

Embodiment 2

[0111]1) Measure 120 parts of a magnetite ore powder in Liaoning, 3.5 parts of a bentonite in Hunan, 0.18 parts of nanometer titanium dioxide, 0.12 parts of micrometer vanadium pentoxide, 0.12 parts of micrometer cerium oxide, and 28 parts of coal powder. Stir and mix uniformly, add 0.8 parts of high elastic modulus polyethylene fiber in 4 batches during the stirring process to obtain the final 3D printing mixture.

[0112]2) Then use a 3D printing device to print the above 3D printing mixture in batches according to a preset programming procedure to obtain honeycomb pellets with a particle size of 12mm, and then place the honeycomb pellets in an oven at 105°C for 3 hours. .

[0113]3) Then put the above-mentioned dried honeycomb pellets in a muffle furnace at 800°C for preheating for 10 minutes, and then heat the muffle furnace to 1000°C for roasting for 1.5 hours and then directly cooling with cold water to obtain roasting mine.

[0114]4) Finally, the roasted ore is crushed and ground and...

Embodiment 3

[0121]1) Proportionally measure 120 parts of mixed mineral powder of a magnetite in Liaoning and a hematite concentrate in Australia (with a ratio of 1:1), 4.0 parts of a bentonite in Hunan, 0.2 parts of nano-sized titanium dioxide, and micron-sized pentoxide 0.1 part of vanadium, 0.04 part of micron-level tungsten trioxide, 0.08 part of micron-level cerium oxide, 30 parts of coal powder are stirred and mixed uniformly, and 0.8 parts of polyurethane elastic fiber is added in 4 batches during the stirring process to obtain the final 3D printing mixture material.

[0122]2) Then use 3D printing equipment to print the above 3D printing mixture in batches according to the preset programming procedure to obtain honeycomb pellets with a particle size of 11mm, and then place the honeycomb pellets in an oven at 105°C for 3 hours. .

[0123]3) Then put the above-mentioned dried honeycomb pellets in a muffle furnace at 700°C for preheating for 12 minutes, and then heat the muffle furnace to 950°C f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com