Preparation method of Ni0. 85Se@NC electro-catalytic material

A technology of electrocatalytic materials and nanosheets, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve problems such as phase and electronic structure regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a method for preparing nickel-based metal-organic framework nanosheets, which specifically includes the following steps:

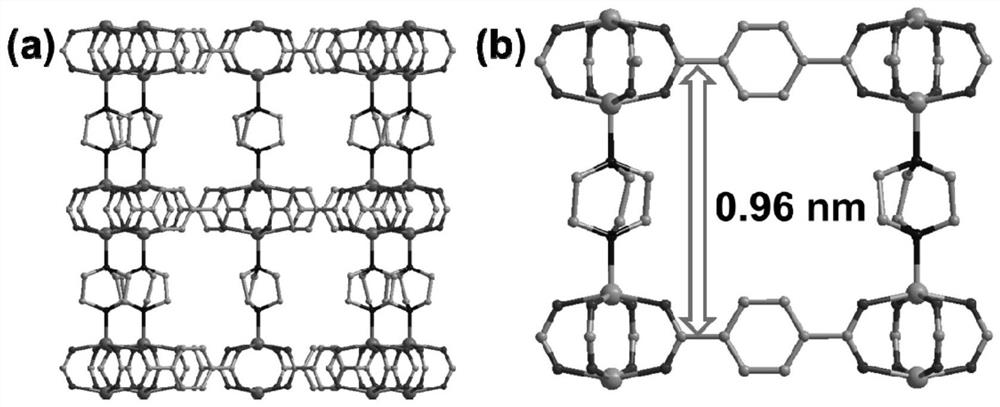

[0051] Preparation of Ni-MOF nanosheets: First, 0.145g (0.5mmol) Ni(NO 3 ) 2 ·6H 2 O, 0.056g (0.5mmol) DABCO, 0.105g (0.5mmol) H 3 BTC and 1 g of PVP were dissolved in DMF (10 mL) solution. The solution was stirred at room temperature at a stirring speed of 600 rpm for 30 minutes, then transferred to a 25 mL reaction axe, and placed in an oven at 120° C. for 24 hours after packaging. After cooling to room temperature naturally, centrifuge three times with DMF and methanol to remove unreacted residues and solvent molecules to obtain light green Ni-MOF powder. Finally, the activated Ni-MOF nanosheets were obtained by vacuum drying at 120 °C for 12 h.

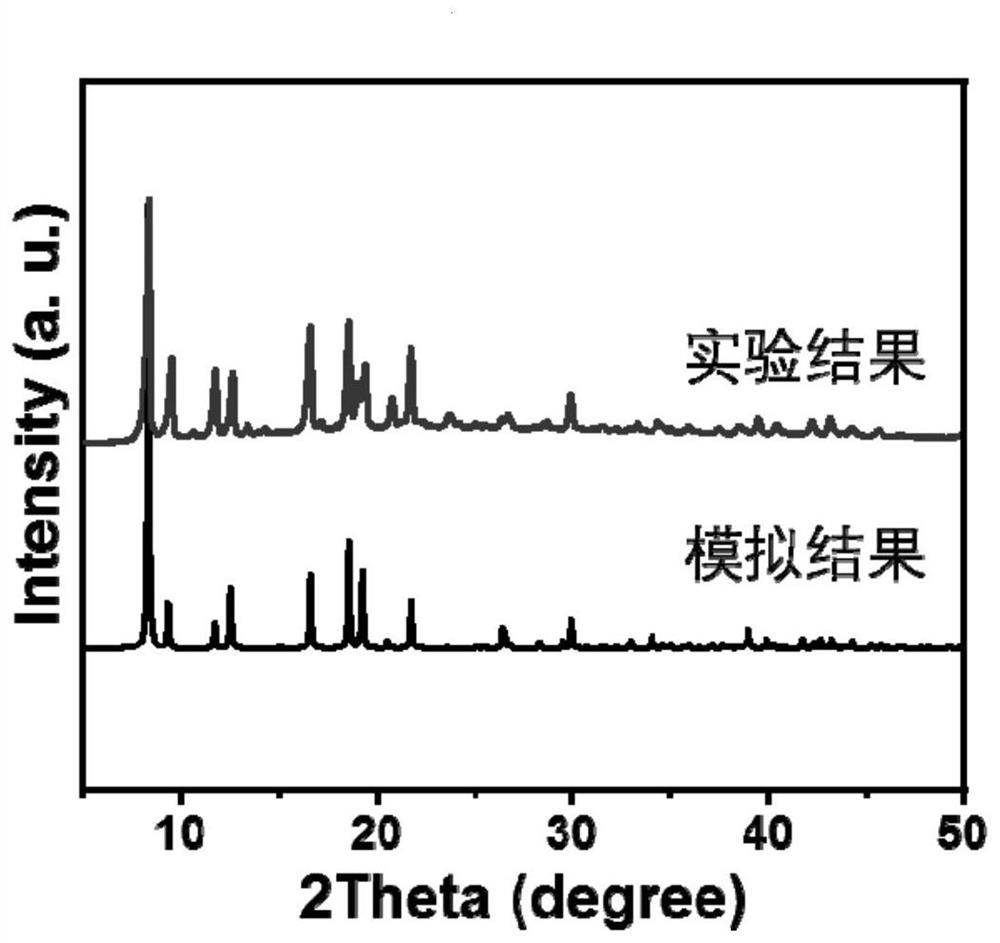

[0052] figure 1 For the XRD pattern of the Ni-MOF nanosheets prepared in Example 1, it can be seen that the X-ray diffraction pattern of the synthesized Ni-MOF is in good ...

Embodiment 2

[0059] This embodiment provides a method for preparing Ni@NC, which specifically includes the following steps:

[0060] Take 100 mg of green Ni-MOF nanosheets, grind them in a mortar for 10 min, transfer them to a square porcelain boat in a tube furnace, and heat them at 5 °C min under an argon atmosphere. -1 The heating rate was heated from room temperature to 600 °C, and maintained for 2 h, and the black powder was obtained after waiting for natural cooling, which was recorded as Ni@NC.

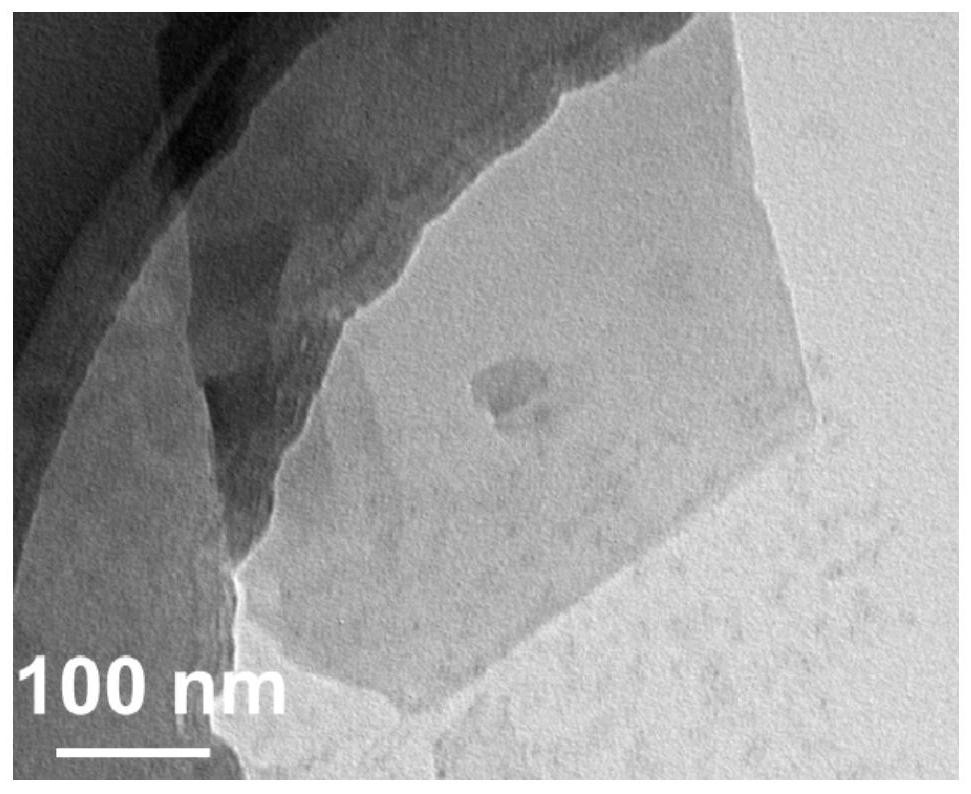

[0061] Figure 4 The TEM image of the Ni@NC electrocatalytic material with core-shell structure prepared for Example 2 shows that the surface of the synthesized nanoflakes becomes rough, and many uniformly distributed nanoparticles appear.

[0062] Figure 5 The XRD pattern of the Ni@NC electrocatalytic material with core-shell structure prepared in Example 2 proves that the synthesized material matches well with Ni (PDF#04-0850) and has a high phase purity.

Embodiment 3

[0064] This example provides Ni 0.85 The preparation method of Se@NC specifically includes the following steps:

[0065] (1)NiSe 2 Preparation of @NC: Prepare and weigh 50 mg of black powder Ni@NC and 200 mg of selenium powder in a mortar, mix them evenly, transfer them to a square porcelain boat in a tube furnace, and heat them at 5°C min under an argon atmosphere. -1 The heating rate is from room temperature to 350 ° C, the reaction is maintained for 2 h, and the temperature is naturally lowered to obtain nitrogen-doped carbon-coated nickel diselenide nanoparticles, named NiSe 2 @NC

[0066] (2)Ni 0.85 Preparation of Se@NC: The obtained 50mg NiSe 2 @NC is placed in a square porcelain boat in a tube furnace, and the tube furnace is heated at 800 °C for 2 hours, and after cooling down to room temperature, nitrogen-doped carbon-coated nickel selenide nanoparticles are obtained, denoted as Ni 0.85 Se@NC.

[0067] Figure 6 It is the core-shell structure NiSe prepared in e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com