Ultrafine grinding device system for battery-grade lithium hydroxide

A lithium hydroxide and ultra-fine grinding technology, applied in grain processing and other directions, can solve the problems of product quality decline, high fine powder content, unqualified products, etc., and achieve the effects of reducing external leakage, reducing loss and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The preferred embodiments of the present invention are described in detail below, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

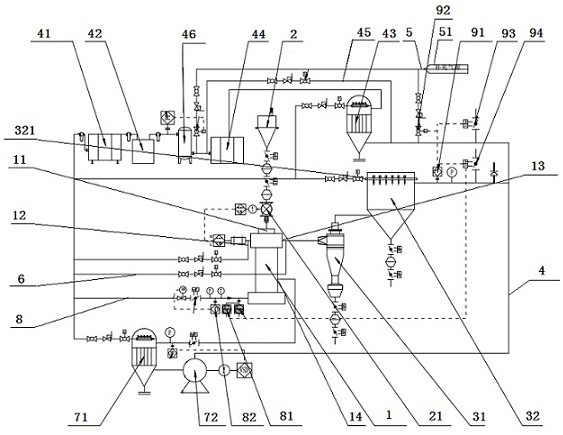

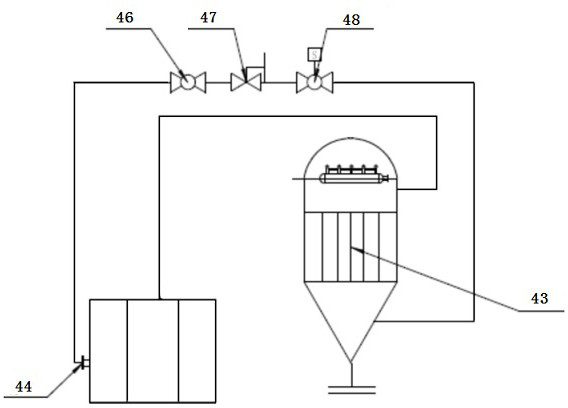

[0025] Refer to the attached figure 1 As shown, the ultra-fine pulverization device system for battery-grade lithium hydroxide, the main body of which is a jet mill host 1, and the jet mill host 1 is provided with a feeding port 11, an air inlet 12, and a discharging port 13, and the feeding port 11 is connected to Feeding hopper 2, a star-shaped feeding valve 21 is provided on the pipeline connecting the feeding hopper 2 and the feeding port 11, the discharge port 13 is connected to the cyclone separator 31 and the dust collector 32, and the gas circulation pipeline 4 is provided with carbon dioxide removal The device 41, the cold dryer 42, the first air filter 43, the gas circulation pipeline ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com