Adhesive resin for outer layer of aluminum-plastic film of lithium battery as well as preparation and application of adhesive resin

A technology of adhesives and aluminum-plastic films, applied in adhesives, secondary batteries, battery pack parts, etc., to meet application performance requirements, excellent hydrolysis resistance, and improve flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

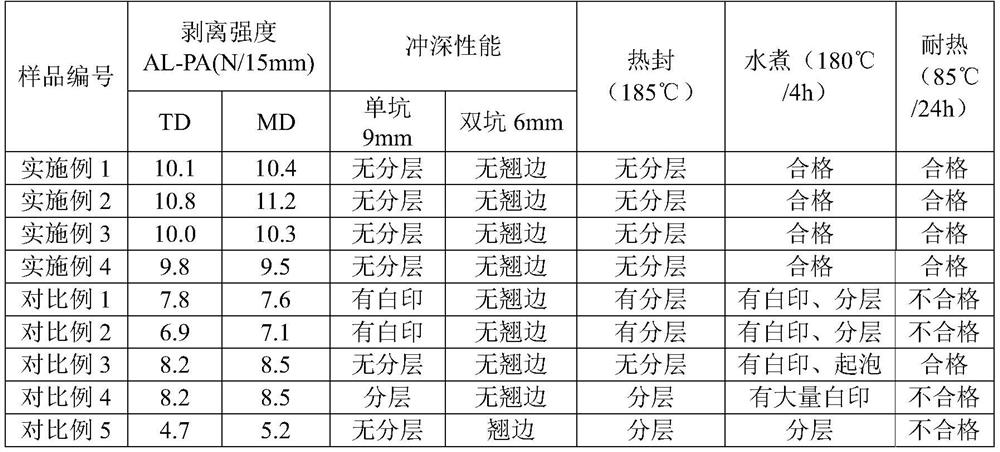

Examples

Embodiment 1

[0032]Add 580.5 grams of terephthalic acid, 720.6 grams of isophthalic acid, 317.0 grams of sebacic acid, 496 grams of ethylene glycol, 128.1 grams of 1,6-hexanediol, 6.5 grams of 3-methylpentane into a 3L polymerization reactor Diol, 1.0 g of antimony acetate catalyst, heat up to 240°C within about one hour, adjust the distillation rate of the generated water, keep the pressure in the kettle at 0.2-0.3MPa, and the temperature of the top of the water distillation tower is lower than 140°C until the amount of distilled water Reach 170 grams, complete esterification reaction. Turn on the vacuum system, adjust the vacuum in the kettle to about 40-80Pa for about half an hour, and at the same time, the temperature rises to 275°C to start the polycondensation reaction, react under this condition for 2.5 hours, and discharge to obtain carboxyl-terminated polyester.

[0033] The polyester obtained above was tested by GPC to have a molecular weight Mn of 7800, an acid value of 13.9 mgK...

Embodiment 2

[0036] Add 824.0 grams of isophthalic acid, 317.0 grams of adipic acid, 378.2 grams of ethylene glycol, 98.4 grams of 3-methyl-1,5-pentanediol, and 1.0 grams of antimony trioxide into a 3L polymerization reactor, within about one hour Raise the temperature to 250°C, adjust the distillation rate of the generated water, keep the pressure in the kettle at 0.25-0.3MPa, and keep the temperature at the top of the distillation tower below 120°C until the amount of distilled water reaches 90 grams to complete the esterification reaction. Turn on the vacuum system, adjust the vacuum in the kettle to about 60Pa for about half an hour, and at the same time, the temperature rises to 280°C to start the polycondensation reaction, react under this condition for 3 hours, and discharge to obtain carboxyl-terminated polyester.

[0037] The polyester obtained above was tested by GPC to have a molecular weight Mn of 8600, an acid value of 12.80 mgKOH / g, and a hydroxyl value of 0.28 mgKOH / g.

[00...

Embodiment 3

[0040] Add 580.5 grams of phthalic acid, 720.6 grams of isophthalic acid, 217.0 grams of adipic acid, 612.4 grams of 1,2-propylene glycol, 128.1 grams of 1,4-butanediol, and 6.5 grams of trimethylol in a 3L polymerization reactor Propane, 1.0g of antimony acetate, heat up to 260°C in about one hour, adjust the distillation rate of the generated water, keep the pressure in the kettle at 0.25-0.3MPa, keep the temperature at the top of the distillation tower below 120°C, until the distilled water reaches 165g , to complete the esterification reaction. Turn on the vacuum system, adjust the vacuum in the kettle to about 145Pa for about half an hour, and at the same time, the temperature rises to 275°C to start the polycondensation reaction, react under this condition for 2.5 hours, and discharge to obtain carboxyl-terminated polyester.

[0041] The polyester obtained above was tested by GPC to have a molecular weight Mn of 5200, an acid value of 21.2 mgKOH / g, and a hydroxyl value o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com