A method for preparing optical fiber quantum probes with controllable diamond particle doping concentration

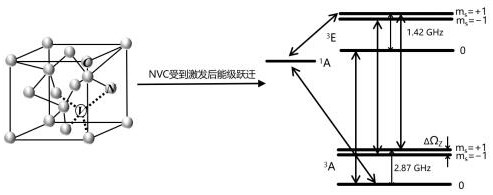

A diamond particle and doping concentration technology, applied in the size/direction of the magnetic field, using magneto-optical equipment for magnetic field measurement, thermometers, etc., can solve the problem of inability to accurately control the concentration of diamond particles, large-scale production, and low repeatability, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

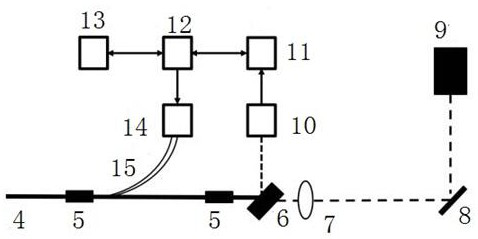

Method used

Image

Examples

Embodiment 1

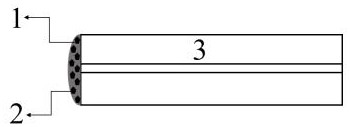

[0026] exist figure 2 Among them, the optical fiber probe coated with gel doped with nano-diamond particles containing NV color centers in this embodiment consists of a sol-gel film 1 , nano-diamond particles 2 containing NV color centers, and an optical fiber 3 . The shape of the sol-gel film 1 in this embodiment is hemispherical with a certain curvature, which is caused by the surface tension generated during the preparation process of the pulling method. The size of the nano-diamond particles 3 containing NV color centers doped in the sol-gel is not limited, and the usable particle size ranges from tens of nanometers to hundreds of nanometers.

Embodiment 2

[0028] figure 2 Among them, the thickness of the sol-gel 1 on the end face of the optical fiber 3 can be controlled by the pulling speed of the stepping motor, which can realize the preparation of optical fiber quantum probes with different thicknesses of nano-diamond particle films containing NV color centers.

Embodiment 3

[0030] figure 2 Among them, sol-gel 1 can be replaced with different types of sol-gel materials according to actual needs, and is not limited to a single sol-gel material; optical fiber 3 can use single-mode optical fibers, multi-mode optical fibers and photonic crystals Ordinary optical fibers such as optical fibers or special optical fibers are not limited to a single type of optical fiber.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com