Acid-resistant salt-tolerant microbial agent for degrading kitchen garbage and preparation method thereof

A microbial agent and kitchen waste technology, applied in the field of microorganisms, to achieve excellent acid resistance and salt resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

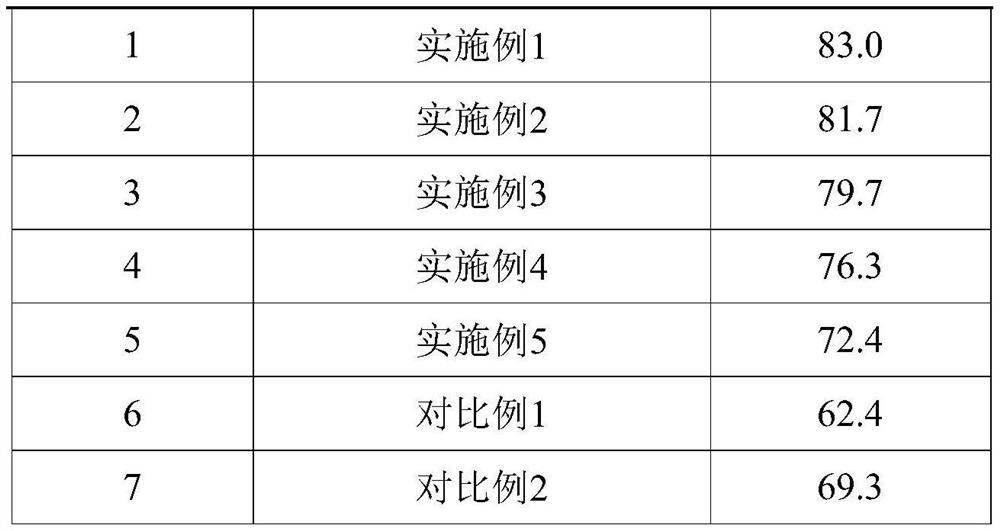

Examples

Embodiment 1

[0024] The preparation method of the acid-resistant and salt-resistant microbial bacterial agent for degrading kitchen waste provided by this embodiment includes the following steps:

[0025] (1) Bacillus thuringiensis bacterial classification, Bacillus coagulans bacterial classification, Bacillus amyloliquefaciens bacterial classification, Bacillus subtilis bacterial classification are respectively inoculated into the shaking flask that is equipped with the activation medium of 25% by volume ratio, respectively at temperature Cultivate for 18 hours at 35-40°C and shaker flask rotation speed 180r / min. The activated medium is beef extract peptone liquid medium; the activated Bacillus thuringiensis strains, Bacillus coagulans strains, Bacteria and Bacillus subtilis were subjected to two gradient cultures respectively. The conditions for each gradient culture were: temperature 28-32°C, stirring speed 150r / min, culture time 12h, and the pH value of the first gradient medium was 5.5...

Embodiment 2

[0029] Repeat step (1) to step (2) of Example 1, take the following raw materials by weight: 7 parts of Bacillus thuringiensis bacterium liquid, 9 parts of Bacillus coagulans bacterium liquid, 2 parts of Bacillus amyloliquefaciens bacterium liquid part, 8 parts of Bacillus subtilis bacterium liquid, 0.5 part of saccharomyces bacterium liquid, 0.5 part of Aspergillus oryzae bacterium liquid; The yeast liquid and the Aspergillus oryzae liquid are inoculated in the fermentation medium, and fermented and cultivated for 36 hours at a temperature of 25-35°C and a stirring speed of 240r / min to obtain an acid-resistant and salt-tolerant microbial bacterial agent, wherein the fermentation culture The base is: molasses 4%, corn steep liquor powder 8%, sodium chloride 4%, water balance, and the pH value is 4.

Embodiment 3

[0031]Repeat step (1) to step (2) of Example 1, and take the following raw materials in parts by weight: 9 parts of Bacillus thuringiensis bacterium liquid, 8 parts of Bacillus coagulans bacterium liquid, 4 parts of Bacillus amyloliquefaciens bacterium liquid Parts, 6 parts of Bacillus subtilis bacterial liquid, 1 part of saccharomyces bacterial liquid, 1 part of Aspergillus oryzae bacterial liquid; The yeast liquid and the Aspergillus oryzae liquid are inoculated in the fermentation medium, and fermented and cultivated for 36 hours at a temperature of 25-35°C and a stirring speed of 240r / min to obtain an acid-resistant and salt-tolerant microbial bacterial agent, wherein the fermentation culture The base is: molasses 4%, corn steep liquor powder 8%, sodium chloride 4%, water balance, and the pH value is 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com