A kind of indigestible branched glucan and its processing method

A processing method and indigestible technology, which are applied in the field of indigestible branched glucan and its processing, can solve the problems that the quality and quality cannot meet the individual needs of consumers, the production cost is high, the research start is late, and the like, and social benefits are achieved. and significant economic benefits, improving people's health, and increasing the value of agricultural and sideline products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] For the acquisition process of α-glucosidase, see the literature Microbial Starch-Converting Enzymes: Recent Insights and Perspectives, Comprehensive Reviews in Food Science and Food Safety, 2018, 17(5): 1238-1260, including enzyme gene mining, engineering bacteria construction, Fermentation and production of enzymes.

[0031] Specifically, the α-glucosidase gene derived from microorganisms such as Aspergillus niger, Acremonium, Paecilomyces or Paenibacillus is connected to the expression vector pET-15b(+) to obtain a recombinant plasmid. The recombinant plasmid was transformed into E.coil competent cells by chemical transformation, and 1 mL of LB medium was added, and cultured in a shaker at 37ºC, 200 r / min for 1-1.5 h; 100-200 μL of the above bacterial solution was taken , spread on LB plates containing ampicillin (Amp), and then cultured in a 37ºC incubator for 12 h. Successfully transformed single colonies were picked on LB plates and placed in LB liquid medium con...

Embodiment 2

[0033] Take by weighing 10g corn starch and be made into 10% starch milk with mass percent concentration, be placed in a boiling water bath and heated to complete gelatinization; Treat that the temperature is reduced to 60 ° C, add the α-amylase of 200 U / g starch and be incubated for 0.5 h, Subsequently, 100 U / g starch α-glucosidase was added to continue the reaction for 1 h; the enzyme was inactivated by heating, centrifuged, and the obtained supernatant was dried to obtain a branched glucan product. In this process, the DE value of α-amylase hydrolyzed starch chain was 7.3.

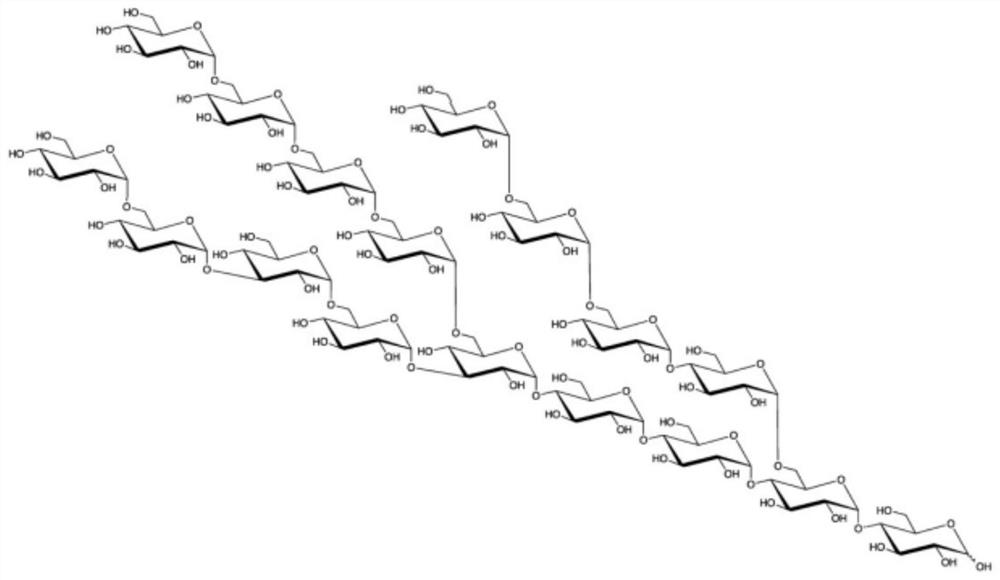

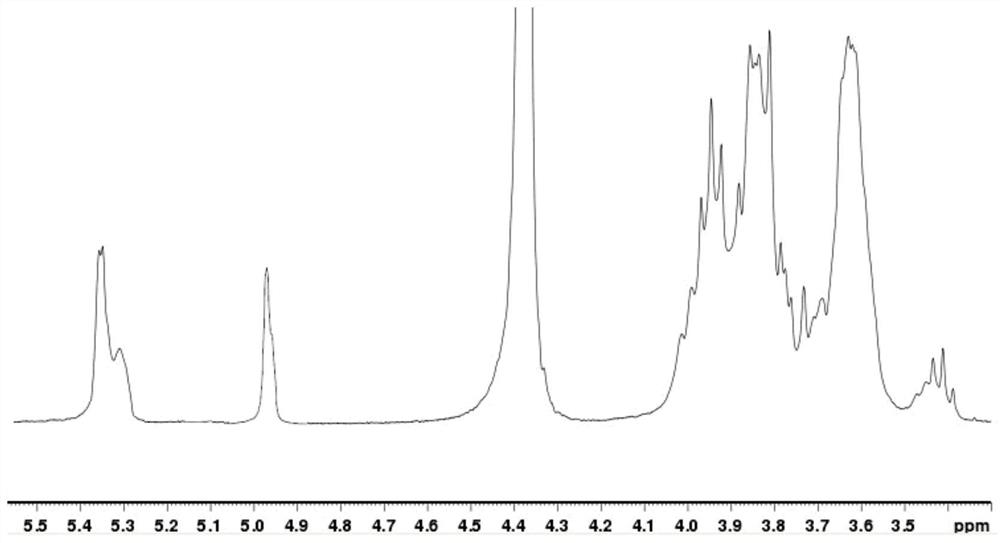

[0034] After analysis and determination, it can be seen that the average molecular weight of the prepared branched glucan is 4800 g / mol, the content of α-1,3 bonds is 8.2%, the content of α-1,6 bonds is 49%, and the proportion of indigestible nutrient fragments reaches 80%. %. figure 1 and figure 2 They are the structural schematic diagram and NMR chart of the prepared indigestible branched glucan, r...

Embodiment 3

[0036] Take by weighing 40g wheat starch and be made into 40% starch milk with mass percent concentration, be placed in boiling water bath and be heated to complete gelatinization; Treat that temperature is down to 30 DEG C, add the α-amylase of 100 U / g starch and be incubated for 1 h, Subsequently, 20 U / g starch α-glucosidase was added to continue the reaction for 12 hours; the enzyme was inactivated by heating, centrifuged, and the obtained supernatant was dried to obtain a branched glucan product. In this process, the DE value of α-amylase hydrolyzed starch chain was 5.5.

[0037] After analysis and determination, it can be seen that the average molecular weight of the prepared branched glucan is 6100 g / mol, the content of α-1,3 bonds is 7.5%, the content of α-1,6 bonds is 60%, and the proportion of indigestible nutrient fragments is 83%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com