Method for producing agricultural seaweed extracting solution by physical and biological combination method and seaweed extracting solution

A technology of seaweed extract and combined method, applied in botany equipment and methods, chemicals for biological control, plant growth regulators, etc., can solve the problems of inability to store for a long time, easy corruption of seaweed extract, and preservation of active ingredients Short time and other problems, to achieve the effect of improving fertilizer utilization rate, avoiding the reduction of material activity, and low molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

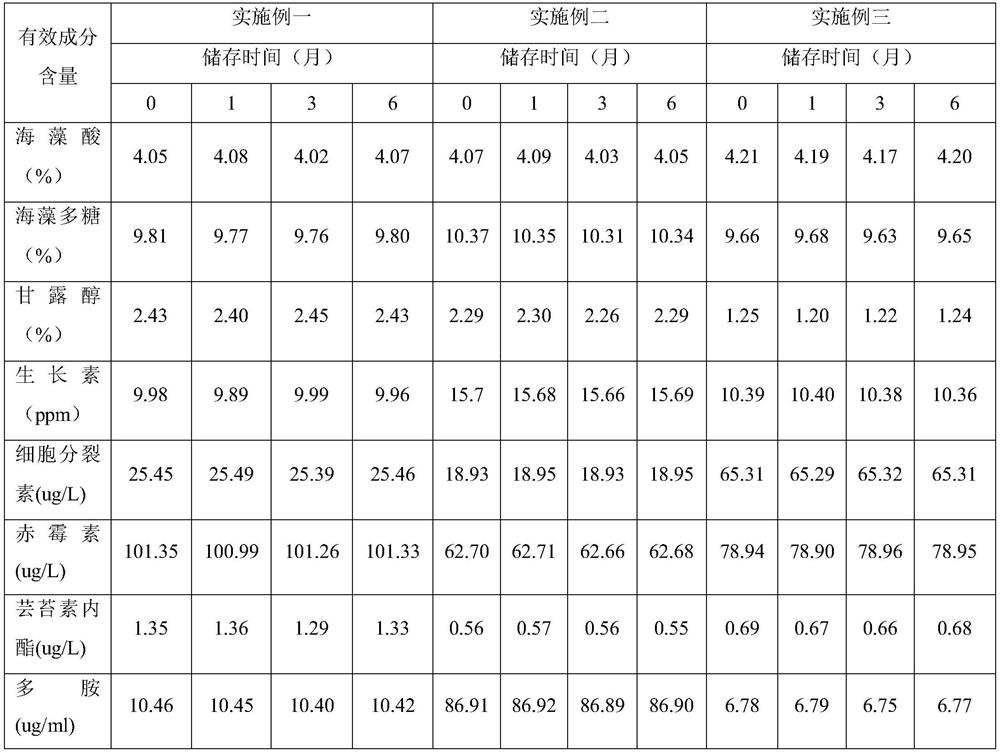

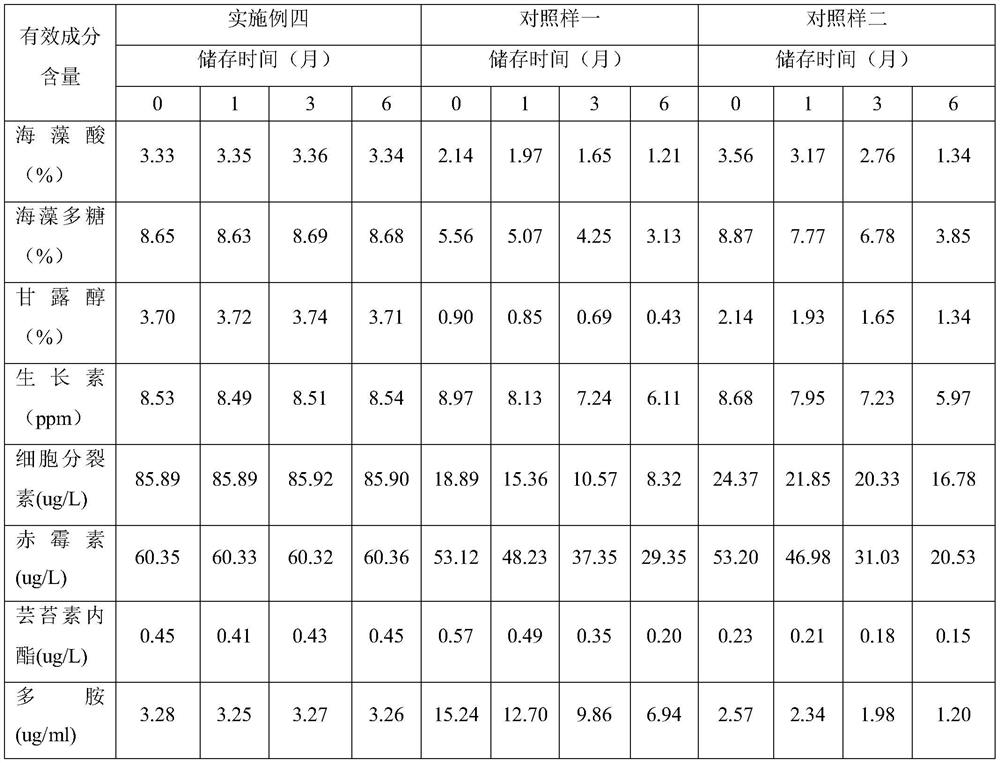

Examples

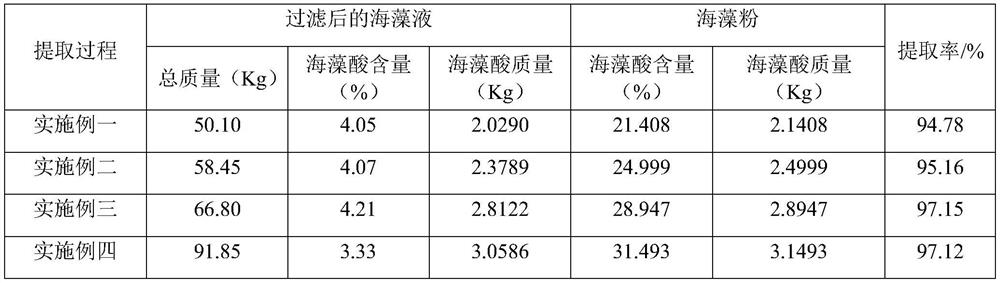

Embodiment 1

[0035] A method for producing agricultural seaweed extract by a combination of physical and biological methods of the present invention comprises the following steps:

[0036] 1) Pretreatment: take dried macroalgae, crush it to 40 mesh, and obtain macroalgae powder;

[0037] 2) Breaking the wall: Take the anti-algae agent, add 10Kg of macroalgae powder obtained in step 1) and 50Kg of the anti-alkali agent into the reaction kettle in turn, turn on the stirring, mix evenly, perform high-pressure homogenization treatment for 20 minutes, and the homogenization pressure is 80MPa. Break the wall and get a mixture;

[0038] This life preserving agent is that pH value is 6.6 and concentration is 0.2mol / L phosphate buffer solution, and its preparation method is:

[0039] a) 0.2mol / L NaH 2 PO 4 Solution preparation: weigh NaH 2 PO 4 2H 2 O 31.2g or NaH 2 PO 4 ·H 2 O27.6g, add water to dissolve, and dilute to 1000mL;

[0040] b) 0.2mol / L Na 2 HPO 4 Solution preparation: weigh...

Embodiment 2

[0046] A method for producing agricultural seaweed extract by a combination of physical and biological methods of the present invention comprises the following steps:

[0047] 1) Pretreatment: Take the dried Ascophyllum nodosum, and use a pulverizer to pulverize it to 60 mesh to obtain Ascophyllum nodosum powder;

[0048] 2) Breaking the wall: Take the retaining agent, add 10Kg of Ascophyllum nodosum powder and 60Kg of the retaining agent obtained in step 1) into the reaction kettle in turn, turn on the stirring, mix evenly, ultrasonic 20min, the ultrasonic power is 400W, and physically break the wall. get a mixture;

[0049] This retaining agent is a borate buffer solution with a pH value of 7.4, and its preparation method is:

[0050] a) Preparation of 0.05mol / L borax solution: accurately weigh 19.07g of borax, dissolve in distilled water, and set the volume to 1000mL;

[0051] b) Preparation of 0.2mol / L boric acid: Accurately weigh 12.37g of boric acid, dissolve it in dis...

Embodiment 3

[0057] A method for producing agricultural seaweed extract by a combination of physical and biological methods of the present invention comprises the following steps:

[0058] 1) Pretreatment: Take dried kelp and grind it to 80 mesh with a pulverizer to obtain kelp powder;

[0059] 2) Breaking the wall: Take the anti-aging agent, add 10Kg of kelp powder and 70Kg of the anti-aging agent obtained in step 1) into the reaction kettle in turn, turn on the stirring, mix evenly, shear for 10min, and the shearing speed is 13000r / min, and carry out physical breaking. wall, a mixture;

[0060] This activating agent is a citrate buffer solution with a pH value of 4.8, and its preparation method is:

[0061] a) 0.2mol / L Na 2 HPO 4 Preparation: Weigh Na 2 HPO 4 12H 2 O 71.632g or Na 2 HPO 4 ·7H 2 O53.6g or Na 2 HPO 4 2H 2 O 35.6g, add water to dissolve, and dilute to 1000mL;

[0062] b) Preparation of 0.1mol / L citric acid solution: weigh C 6 h 8 o 7 ·H 2 O 21.014g, add wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com