Preparation method of monodisperse rare earth oxide ultrafine powder

A rare earth oxide, monodisperse technology, applied in the preparation/processing of rare earth metal compounds, rare earth metal oxides/hydroxides, lanthanide oxides/hydroxides, etc., can solve the problem of crystal nucleus growth. Difficult to control conditions, high production cost, particle and particle adsorption and other problems, to achieve the effect of regular product morphology, less product pollution, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

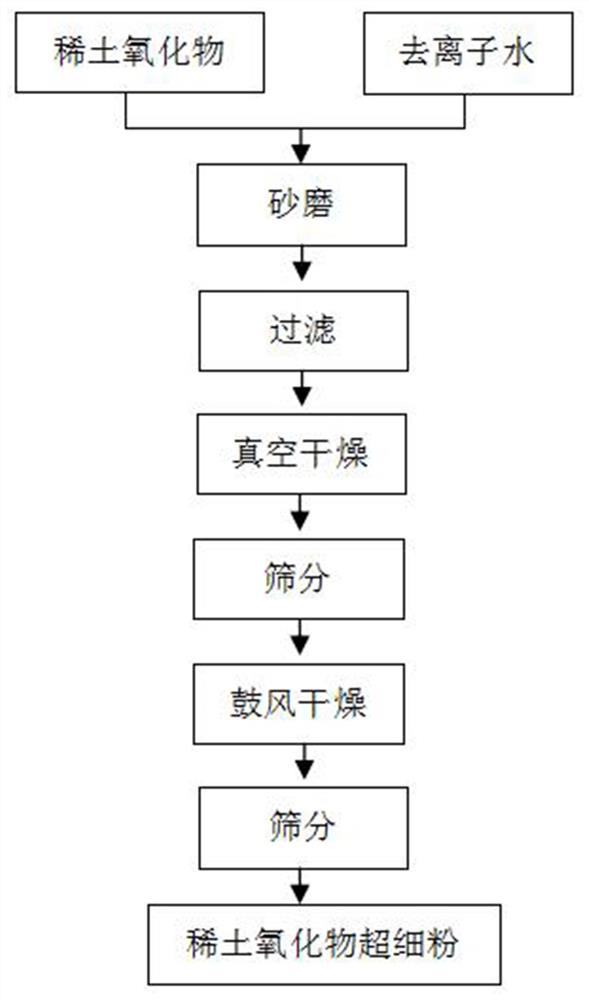

[0027] A preparation method of monodisperse rare earth oxide superfine powder, the steps are as follows:

[0028] Weigh 1200g of high-purity yttrium oxide and 2400g of deionized water, put them in a mixing bucket and stir them. After the stirring is uniform, pump them into a sand mill for ball milling. The speed of the main engine is 850rpm, and the pump speed is 20rpm. After μm, the slurry is pumped out to obtain yttrium oxide slurry;

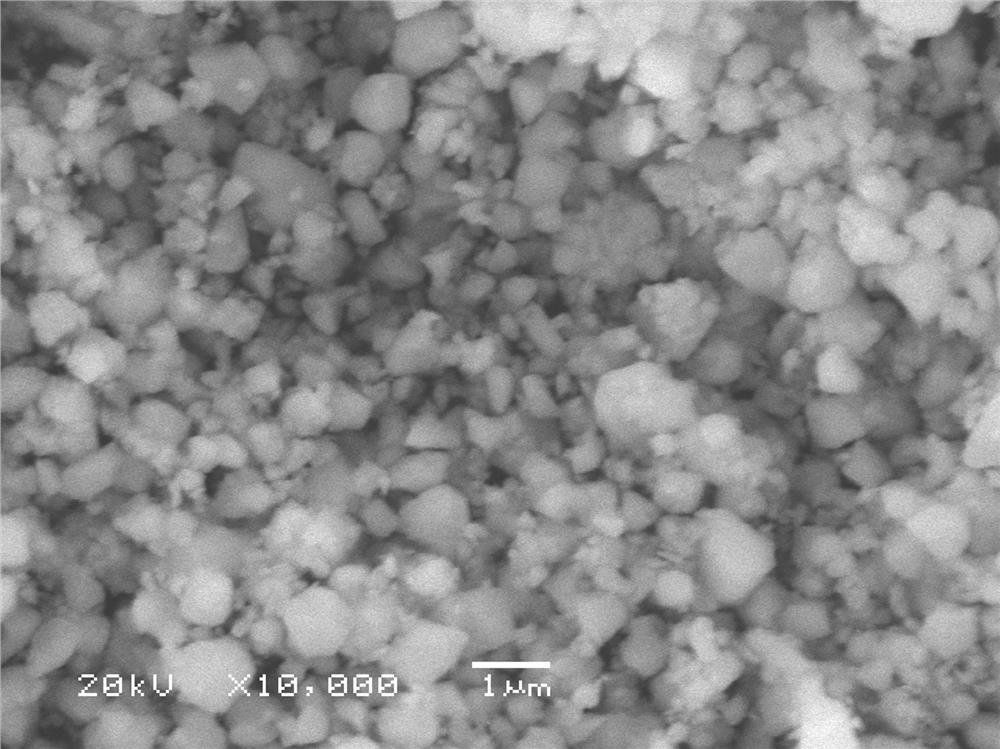

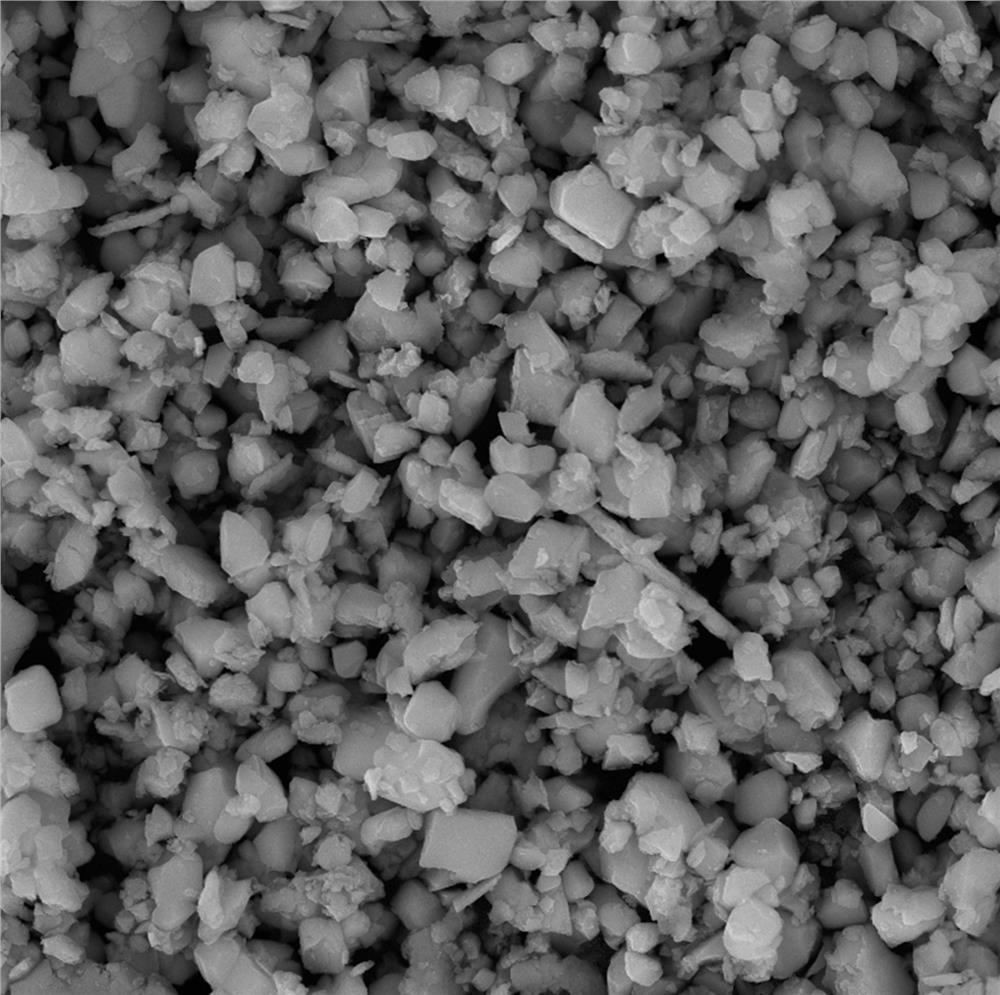

[0029] After filtering the yttrium oxide slurry, put it in a vacuum drying oven, and dry it under vacuum at 45°C for 8 hours until the solid content of the powder is 78%. Blast drying at ℃ for 8 hours. After the yttrium oxide was dried, it was sieved with a 200-mesh sieve to prepare a monodisperse yttrium oxide ultrafine powder with an average particle size D50 of 0.71 μm.

Embodiment 2

[0031] A preparation method of monodisperse rare earth oxide superfine powder, the steps are as follows:

[0032] Weigh 1400g of high-purity cerium oxide and 2100g of deionized water, put them in a mixing bucket and stir them. After stirring evenly, pump them into a sand mill for ball milling. The speed of the main machine is 1000rpm, and the pump speed is 32rpm. After μm, the slurry is pumped out to obtain cerium oxide slurry;

[0033] After filtering the cerium oxide slurry, place it in a vacuum drying oven, and dry it under vacuum at 55°C for 6 hours until the solid content of the powder reaches 75%. Blast drying at ℃ for 10 hours. After the cerium oxide was dried, it was sieved with a 250-mesh sieve to prepare monodisperse cerium oxide superfine powder with an average particle diameter D50 of 0.55 μm.

Embodiment 3

[0035] A preparation method of monodisperse rare earth oxide superfine powder, the steps are as follows:

[0036] Weigh 1500g of high-purity ytterbium oxide and 1800g of deionized water, put them in a mixing bucket and stir them. After stirring evenly, pump them into a sand mill for ball milling. The speed of the host machine is 1200rpm, and the pump speed is 46rpm. After μm, the slurry is pumped out to obtain ytterbium oxide slurry;

[0037] After filtering the ytterbium oxide slurry, place it in a vacuum drying oven, and dry it under vacuum at 60°C for 5 hours until the solid content of the powder is 72%. After sieving with a 120-mesh sieve, place it in a blast drying oven for 140 Blast drying at ℃ for 12 hours. After drying the ytterbium oxide, sieve it with a 300-mesh sieve to prepare a monodisperse ytterbium oxide ultrafine powder with an average particle size D50 of 0.46 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com