Anaerobic granular sludge conditioning agent and preparation method and application thereof

An anaerobic granular sludge and conditioner technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Reactor impact, unfavorable water quality control at the end of the wastewater treatment system, poor biodegradability of surfactants, etc., to improve anaerobic treatment efficiency and load shock resistance, increase bioavailability, and avoid secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

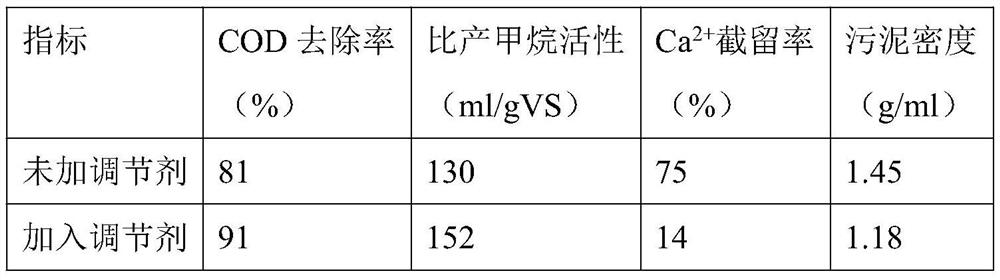

Embodiment 1

[0041](1) 1.5kg of trace elements (including: NH4HCO30.6kg, KH2PO30.3kg, FeSO4·7H2O0.3kg, MnSO4·H2O0.075kg, Al2(SO4)3·18H2O0.075kg, NiSO4·6H2O0.075kg, CoSO4·7H2O0.0375kg, (NH4)6MO7O24·4H2O0.0225kg, H3BO30.015kg);

[0042](2) 1.5 kg of biological factor supplements (including: amino acid 0.525 kg, vitamin 0.3 kg, purine 0.375 kg, pyridine 0.3 kg).

[0043](3) 0.8kg of alkyl polyglycoside surfactant;

[0044](1) Sodium citrate 22kg (industrial grade 98%);

[0045](2) Sodium humate 10kg;

[0046]Mix the above-mentioned raw materials, make up to 100kg with water, and stir in the mixing tank for 2 hours to obtain a liquid that is an anaerobic granular sludge regulator.

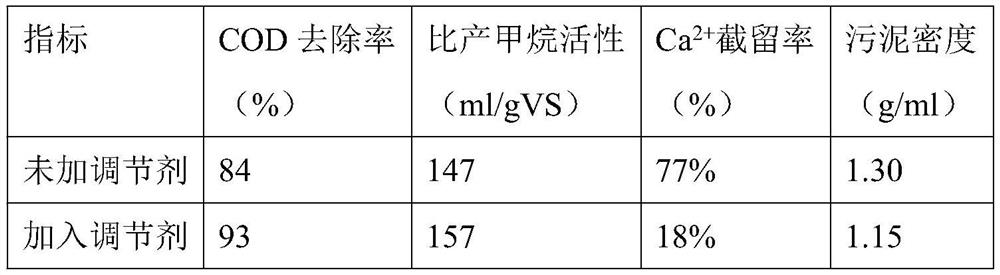

Embodiment 2

[0048]Raw materials used in this example:

[0049](1) 1.5kg of trace elements (including: NH4HCO30.6kg, KH2PO30.3kg, FeSO4·7H2O0.3kg, MnSO4·H2O0.075kg, Al2(SO4)3·18H2O0.075kg, NiSO4·6H2O0.075kg, CoSO4·7H2O0.0375kg, (NH4)6MO7O24·4H2O0.0225kg, H3BO30.015kg);

[0050](2) 1.5 kg of biological factor supplements (including: amino acid 0.525 kg, vitamin 0.3 kg, purine 0.375 kg, pyridine 0.3 kg).

[0051](3) Alkyl polyglycoside surfactant 1kg;

[0052](1) Sodium citrate 25kg (industrial grade 98%);

[0053](2) Sodium humate 10kg;

[0054]Mix the above-mentioned raw materials, make up to 100kg with water, and stir in the mixing tank for 2 hours to obtain a liquid that is an anaerobic granular sludge regulator.

Embodiment 3

[0056]Raw materials used in this example:

[0057](1) Trace elements 2kg (including: NH4HCO30.8kg, KH2PO30.4kg, FeSO4·7H2O0.4kg, MnSO4·H2O0.1kg, Al2(SO4)3·18H2O0.1kg, NiSO4·6H2O0.1kg, CoSO4·7H2O0.05kg, (NH4)6MO7O24·4H2O0.03kg, H3BO30.02kg);

[0058](2) 1.5 kg of biological factor supplements (including: amino acid 0.525 kg, vitamin 0.3 kg, purine 0.375 kg, pyridine 0.3 kg).

[0059](3) Alkyl polyglycoside surfactant 0.5kg;

[0060](1) Sodium citrate 30kg (industrial grade 98%);

[0061](2) Sodium humate 15kg;

[0062]Mix the above-mentioned raw materials, make up to 100kg with water, and stir in the mixing tank for 2 hours to obtain a liquid that is an anaerobic granular sludge regulator.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com