A sludge pyrolysis gasification system

A technology of pyrolysis gasification and sludge, which is applied in the direction of gasification process, pyrolysis treatment sludge, granular/powdered fuel gasification, etc. High viscosity of mud and other problems to achieve the effect of improving the use efficiency and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

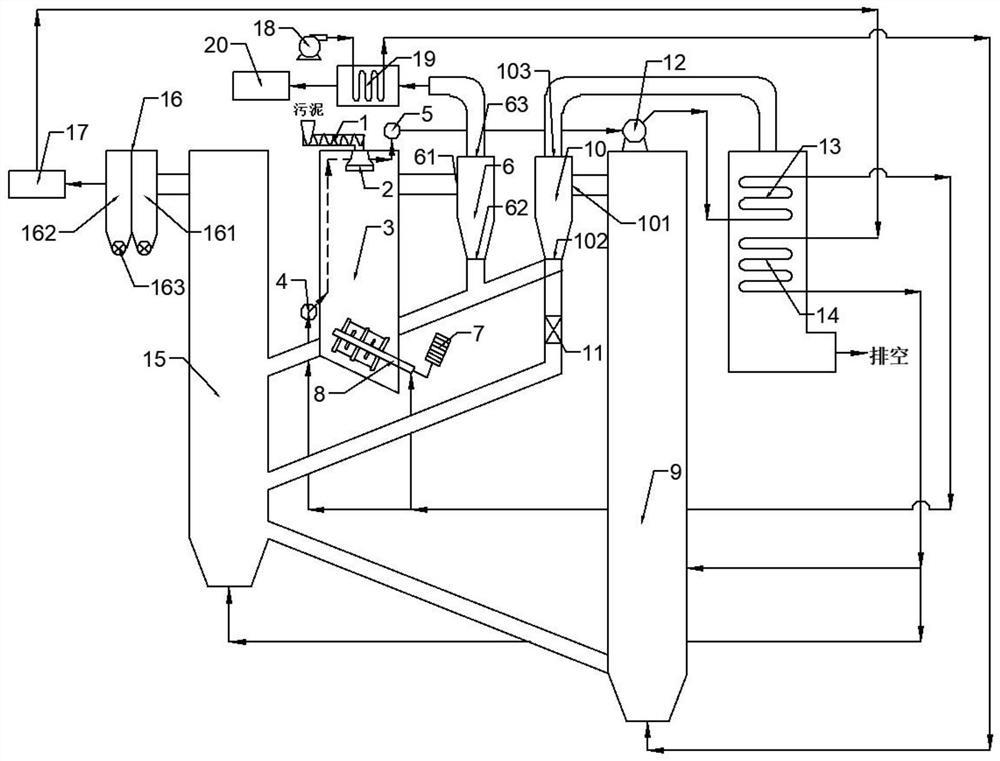

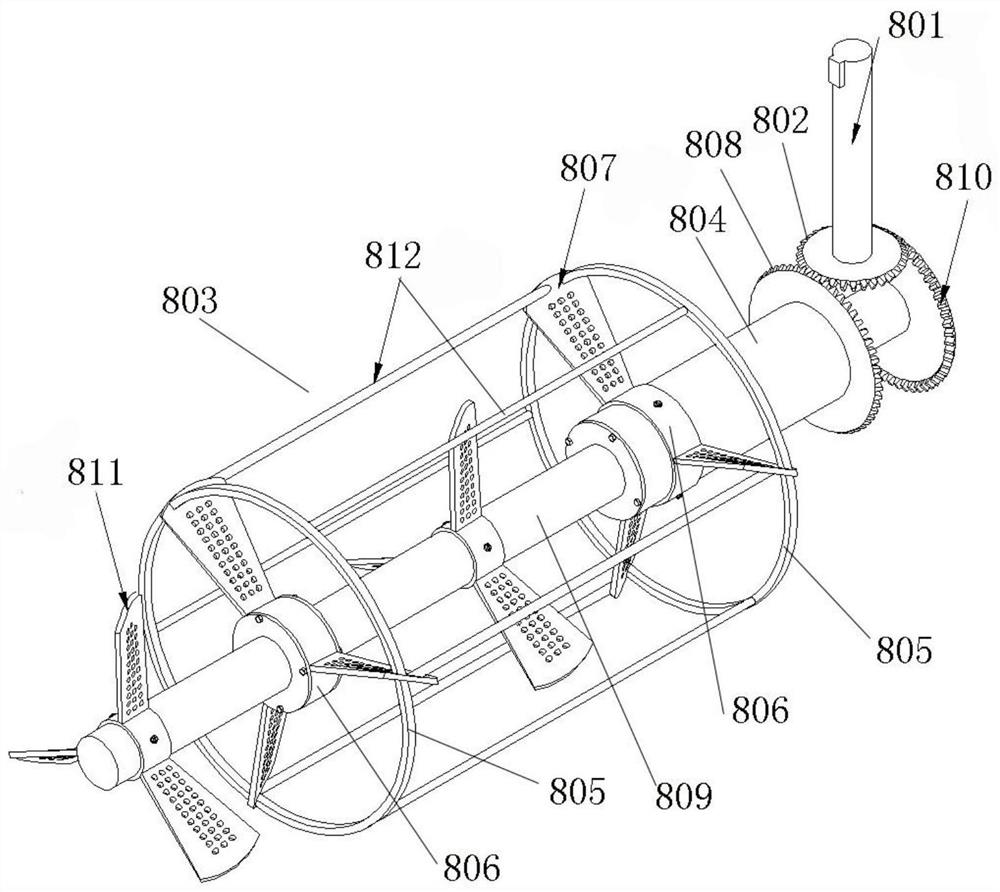

[0029] Such as figure 1 , figure 2As shown, a sludge pyrolysis gasification system includes a sludge thermal drying chamber 3 for thermally drying the sludge. The inner wall of the sludge thermal drying chamber 3 is provided with a steam pipe, The thermal radiation of the superheated steam in the steam pipeline dries the sludge through indirect contact with exothermic heat. A screw feeder 1 is arranged above the sludge thermal drying chamber 3, and a nozzle 2 is also arranged on the top of the sludge thermal drying chamber 3. , connected to the bottom of the screw feeder 1, the raw sludge enters the nozzle 2 through the screw feeder 1, the side and bottom of the nozzle 2 are provided with a number of small holes with a diameter of 8-10mm, and the screw feeder 1 is input The sludge is granulated into small particles by high-speed rotation and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com