Low-tension viscosity-reducing thick oil washing agent for cold production of common thick oil as well as preparation method and application thereof

A sticky oil cleaning agent, low tension technology, applied in chemical instruments and methods, production fluids, earthwork drilling and other directions, can solve the problem of not mentioning oil cleaning efficiency, etc., to improve oil displacement efficiency, emulsification and viscosity reduction ability. , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

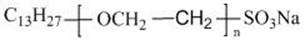

Embodiment 1

[0054] Add 350kg of water into the reaction kettle, control the temperature at 60°C, add 50kg of anhydrous sodium carbonate, stir and dissolve evenly, add 300kg of isomeric tridecanol polyoxyethylene ether sulfonate (n=3) and 100kg of methanol, and stir Evenly, finally add 200kg phenol ether carboxylate (R 1 =8, m=7), and stir evenly to obtain a low-tension heavy oil viscosity-reducing detergent.

Embodiment 2

[0056] Add 340kg of water into the reaction kettle, control the temperature at 58°C, add 60kg of anhydrous sodium carbonate, stir and dissolve evenly, then add 320kg of isomeric tridecanol polyoxyethylene ether sulfonate (n=4) and 100kg of ethanol, Stir evenly, finally add 180kg phenol ether carboxylate (R 1 =9, m=8), and stir evenly to obtain a low-tension heavy oil viscosity-reducing detergent.

Embodiment 3

[0058] Add 330kg of water into the reaction kettle, control the temperature at 56°C, add 70kg of anhydrous sodium carbonate, stir and dissolve evenly, then add 340kg of isotridecyl alcohol polyoxyethylene ether sulfonate (n=3) and 100kg of isopropyl Alcohol, stir evenly, finally add 160kg phenol ether carboxylate (R 1 =10, m=9), and stir evenly to obtain a low-tension heavy oil viscosity-reducing detergent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| interfacial tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| interfacial tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com