Hyperbranched epoxy polymer-nano silicon dioxide composite chrome-free tanning agent and preparation method thereof

A nano-silica, epoxy polymer technology, applied in small raw hides/large raw hides/leather hides/fur chemical treatment, small raw hides/large raw hides/leather/fur treatment, tanning treatment, etc., can solve the problem of tanning problems. Uniform, impermeable, large specific surface area, etc., to achieve good antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of preparation method of hyperbranched epoxy polymer-nanometer silicon dioxide composite chrome-free tanning agent, carry out according to the following steps:

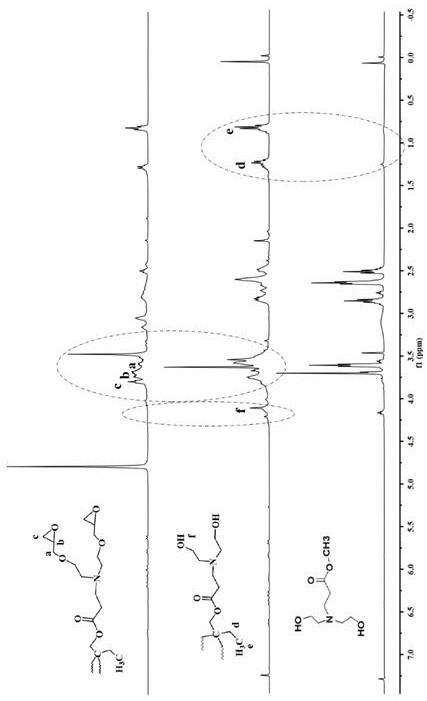

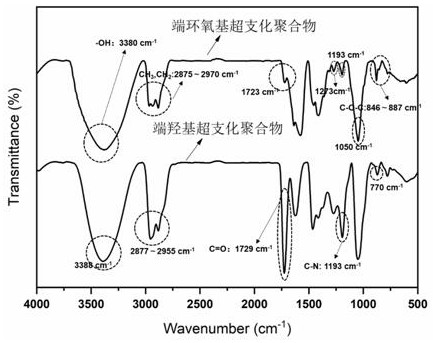

[0042] (1) Preparation of hydroxyl-terminated hyperbranched polymers

[0043] 1) Dissolve 0.5 mol of diethanolamine in 50 mL of anhydrous methanol in the reaction kettle at room temperature and under the protection of nitrogen, then slowly add 1 mol of methyl acrylate dropwise to the completely dissolved mixture, and raise the temperature to 40°C after the addition is completed, Insulated reaction for 4 h, after the reaction was completed, methanol and excess methyl acrylate were distilled off under reduced pressure to obtain a colorless and transparent oily AB 2 monomer;

[0044] 2) 0.16 mol of trimethylolpropane and 2% p-toluenesulfonic acid as catalyst (based on trimethylolpropane and AB 2 The total mass) into the reactor, heated to 110 ~ 120 ° C to completely dissolve the trimethylolpropane, slowly...

Embodiment 2

[0051] A kind of preparation method of hyperbranched epoxy polymer-nanometer silicon dioxide composite chrome-free tanning agent, carry out according to the following steps:

[0052] (1) Preparation of hydroxyl-terminated hyperbranched polymers

[0053] 1) Dissolve 1.0 mol of diethanolamine in 50 mL of anhydrous methanol at room temperature and under the protection of nitrogen in the reaction kettle, then slowly add 2.0 mol of methyl acrylate dropwise to the completely dissolved mixture, and raise the temperature to 40°C after the addition is completed , heat preservation reaction for 4h, after the reaction was completed, methanol and excess methyl acrylate were distilled off under reduced pressure to obtain a colorless and transparent oily AB 2 monomer;

[0054] 2) 0.42 mol of trimethylolpropane and 2% p-toluenesulfonic acid as catalyst (based on trimethylolpropane and AB 2 The total mass) into the reactor, heated to 110 ~ 120 ° C to completely dissolve the trimethylolpropa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com