W-containing high-nickel ternary positive electrode material and preparation method thereof

A cathode material, high nickel technology, applied in the field of high nickel ternary cathode material and its preparation, can solve the problem that the material capacity and cycle performance cannot be effectively improved, the preparation conditions and sintering temperature are different, and the battery system cannot be better matched. problems, to achieve the effect of excellent cycle performance at room temperature and high temperature, good flow performance, pH and residual Li reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

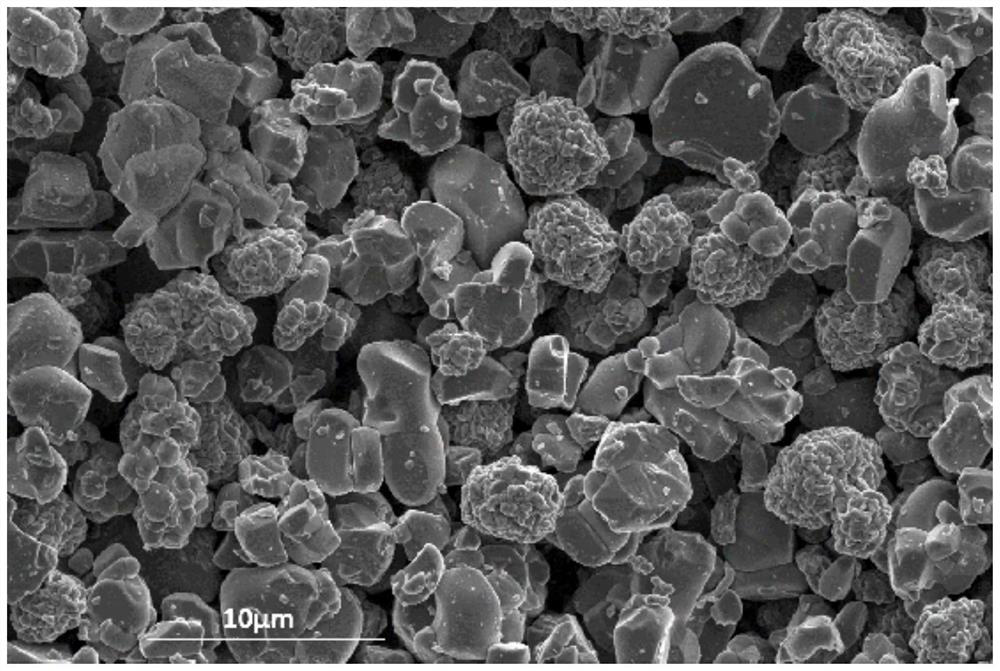

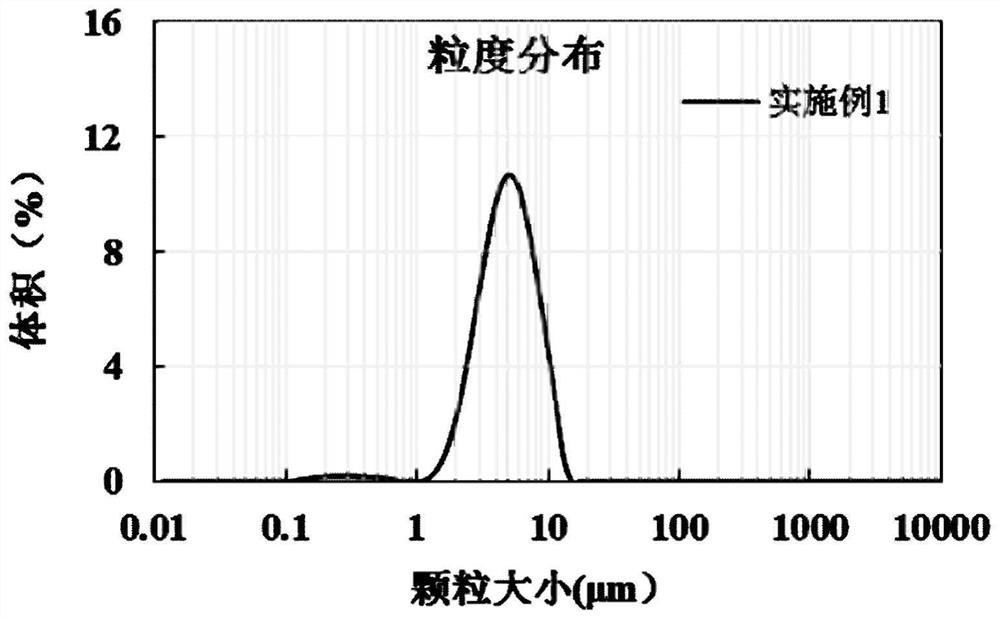

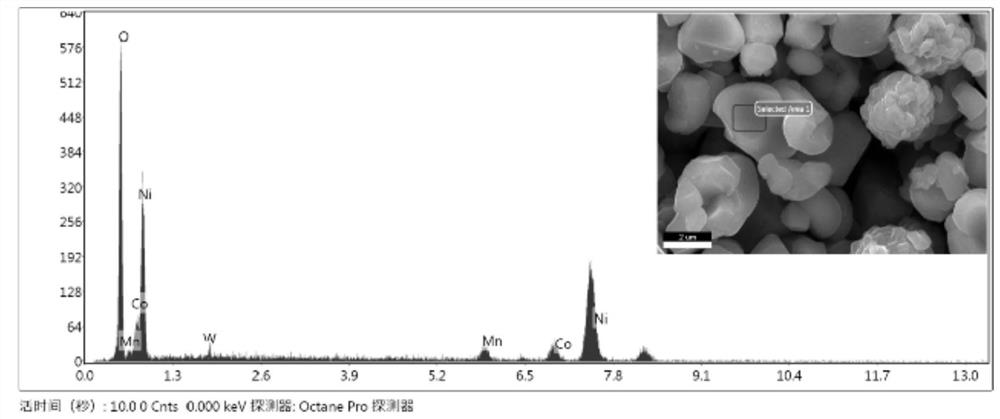

[0049] A kind of W-containing high-nickel ternary cathode material of the present invention, its chemical formula is Li 1.0068 Ni 0.8 co 0.1 mn 0.1 W 0.0008 Al 0.006 o 2 , the high-nickel ternary positive electrode material contains both spherical secondary particles and single crystal particles, the single crystal particles basically do not contain W element, and the spherical secondary particles are doped with W element, The median particle size of the high-nickel ternary cathode material is 4.5 μm, and the specific surface area is 0.68m 2 / g.

[0050] The preparation method of the W-containing high-nickel ternary positive electrode material of this embodiment is as follows:

[0051] (1) According to the molar ratio of Ni, Co, and Mn elements 0.8:0.1:0.1, prepare a mixed solution of 0.8mol / L nickel sulfate, 0.1mol / L cobalt sulfate and 0.1mol / L manganese sulfate; prepare 3mol / L hydroxide Sodium solution and 1mol / L ammonia solution; first use sodium hydroxide solution ...

Embodiment 2

[0058] A kind of W-containing high-nickel ternary cathode material of the present invention, its chemical formula is Li 1.004 Ni 0.88 co 0.09 mn 0.03 W 0.001 Zr 0.003 o 2 , the high-nickel ternary positive electrode material contains both spherical secondary particles and single crystal particles, the single crystal particles basically do not contain W element, and the spherical secondary particles are doped with W element, The median particle size of the high-nickel ternary cathode material is 4.2μm, and the specific surface area is 0.72m 2 / g.

[0059] The preparation method of the W-containing high-nickel ternary positive electrode material of this embodiment is as follows:

[0060] (1) According to the molar ratio of Ni, Co, and Mn elements 0.88:0.09:0.03, prepare a mixed solution of 0.88mol / L nickel sulfate, 0.09mol / L cobalt sulfate and 0.03mol / L manganese sulfate; prepare 3mol / L hydroxide Sodium solution; prepare 1mol / L ammonia solution; first use sodium hydroxid...

Embodiment 3

[0067] A kind of W-containing high-nickel ternary cathode material of the present invention, its chemical formula is Li 1.0029 Ni 0.83 co 0.11 mn 0.06 W 0.0009 La 0.002 o 2 , the high-nickel ternary positive electrode material contains both spherical secondary particles and single crystal particles, the single crystal particles basically do not contain W element, and the spherical secondary particles are doped with W element, The median particle size of the high-nickel ternary cathode material is 5.0 μm, and the specific surface area is 0.80 m 2 / g.

[0068] The preparation method of the W-containing high-nickel ternary positive electrode material of this embodiment is as follows:

[0069] (1) According to the molar ratio of Ni, Co, Mn element 0.83: 0.11: 0.06, prepare the mixed solution of 0.83mol / L nickel sulfate, 0.11mol / L cobalt sulfate and 0.06mol / L manganese sulfate; prepare 3mol / L hydroxide Sodium solution; prepare 1mol / L ammonia solution; at first use sodium hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Median particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com