A laser hot wire tig hybrid welding system suitable for titanium alloy

A welding system and laser welding head technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of low deposition efficiency, large welding stress, and many welding passes, so as to reduce welding stress and residual Deformation, high-precision adaptability, high-speed and high-efficiency welding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments.

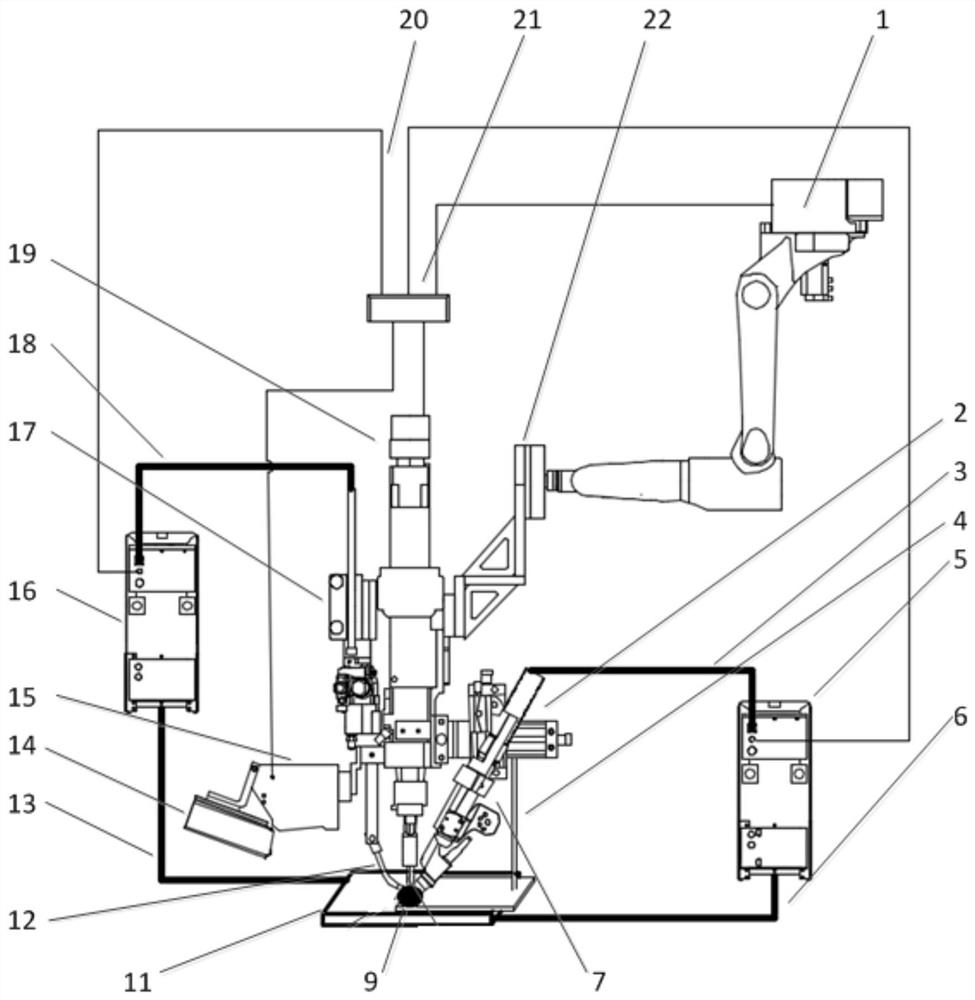

[0020] combine figure 1 , figure 2 , a laser hot wire TIG composite intelligent welding system suitable for titanium alloys of the present invention includes an industrial robot 1, a laser welding head 19, a TIG welding power supply 5, a hot wire power supply 16, a TIG welding torch 7, a TIG wire filling mechanism 17, Wire-filled copper pipe 12, seam tracking sensor 15, CCD camera 14, inert gas protective gas hood device 4, data communication bus 20, switch 21;

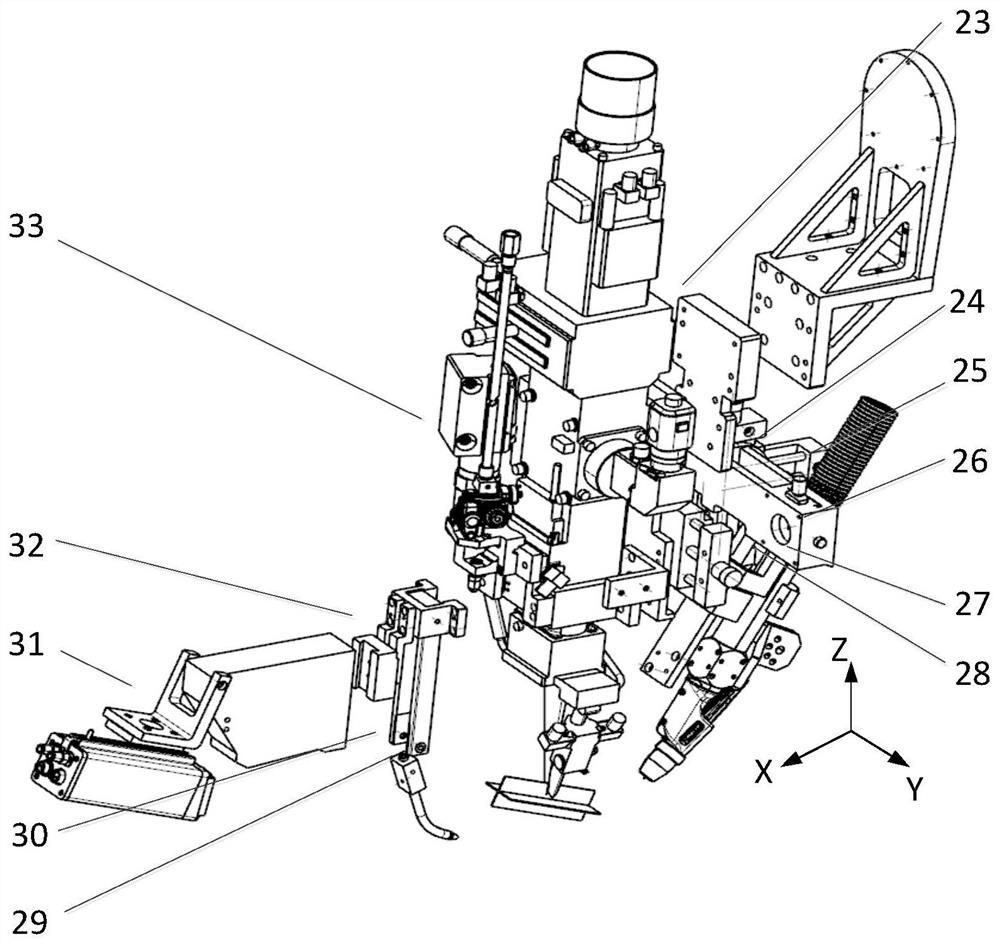

[0021] The end of the industrial machine 1 is provided with an adapter flange 22, and the laser welding head mounting frame 23 is fixed on the laser welding head 19; the industrial machine 1 is connected with the laser welding head mounting frame 23 through the adapter flange 22 to realize industrial The machine 1 controls the movement of the laser welding head 19; the wire-filling...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com