Degradable high-toughness composite material with antibacterial function and preparation method thereof

A composite material, strong and tough technology, applied in the field of degradable, antibacterial, strong and tough composite materials and their preparation, which can solve the problems of easily causing bacterial infection, precipitation of toxic ions, bacterial inflammatory response, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

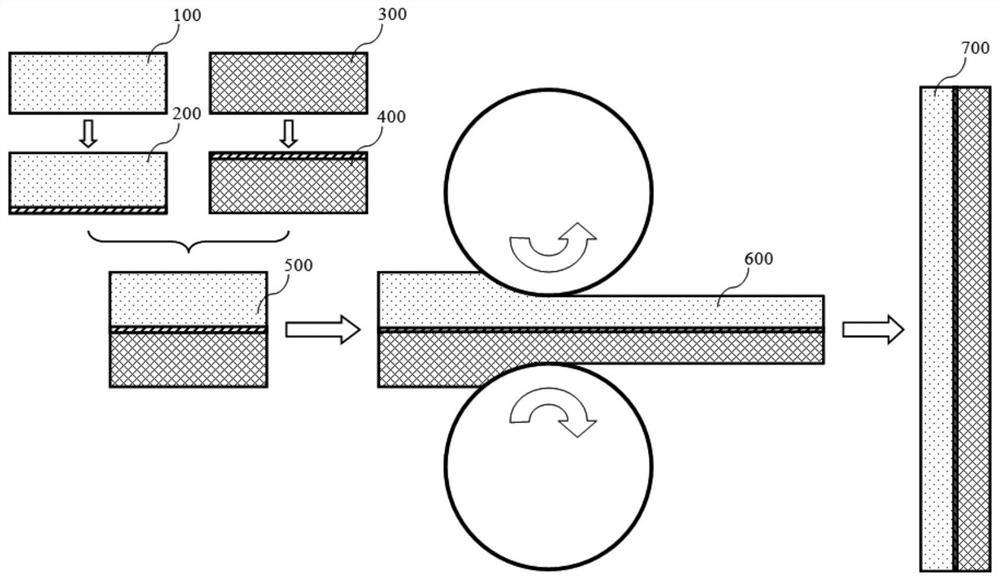

[0111] Embodiment 1: the preparation of composite material

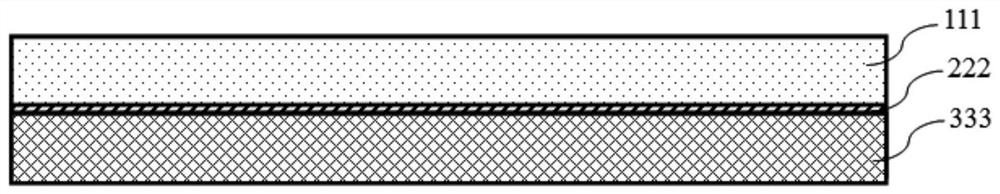

[0112] This example provides a composite material with antibacterial function, degradability and toughness, which includes 60% of magnesium alloy layer, 1% of intermediate alloy layer and 39% of zinc alloy layer according to volume percentage; the intermediate alloy layer is composed of magnesium zinc silver Alloy composition.

[0113] The magnesium alloy layer is composed of magnesium alloy, and the magnesium alloy also includes the following components in terms of mass percentage:

[0114] Ag 4.0%

[0115] Nd 3.0%;

[0116] The zinc alloy layer is composed of zinc alloy, and the zinc alloy also includes the following components in terms of mass percentage:

[0117] Ag 4.0%

[0118] Nd 3.0%;

[0119] The preparation method of above-mentioned magnesium alloy comprises the following steps:

[0120] (1) Weigh Ag, Nd, and Mg (remainder) according to the proportion, and then vacuum smelt. The temperature of vacuum ...

Embodiment 2

[0139] Embodiment 2: the preparation of composite material

[0140] This example provides a composite material with antibacterial function, degradability and toughness, which includes 65% of the magnesium alloy layer, 2% of the intermediate alloy layer and 33% of the zinc alloy layer in terms of volume percentage.

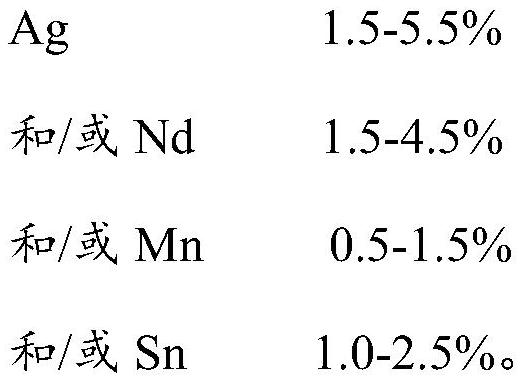

[0141] The magnesium alloy layer is composed of magnesium alloy, and the magnesium alloy also includes the following components in terms of mass percentage:

[0142]

[0143] The zinc alloy layer is composed of zinc alloy, and the zinc alloy also includes the following components in terms of mass percentage:

[0144]

[0145] The preparation method of above-mentioned magnesium alloy comprises the following steps:

[0146] (1) Weigh Ag, Nd, Mn, Sn, Mg (residue) according to the proportion, then vacuum smelt, the temperature of vacuum smelt is 760 ℃, in the process of vacuum smelting, pass into argon to stir, the time of described stirring 50min to obtain a p...

Embodiment 3

[0165] Embodiment 3: the preparation of composite material

[0166] This example provides a composite material with antibacterial function, degradability and toughness, which includes 72% of magnesium alloy layer, 3% of intermediate alloy layer and 25% of zinc alloy layer in terms of volume percentage.

[0167] The magnesium alloy layer is composed of magnesium alloy, and the magnesium alloy also includes the following components in terms of mass percentage:

[0168] Ag 3.0%

[0169] Nd 3.0%

[0170] Mn 1.0%;

[0171] The zinc alloy layer is composed of zinc alloy, and the zinc alloy also includes the following components in terms of mass percentage:

[0172] Ag 3.0%

[0173] Nd 3.0%

[0174] Mn 1.0%;

[0175] The preparation method of above-mentioned magnesium alloy comprises the following steps:

[0176] (1) Weigh Ag, Nd, Mn, Mg (residue) according to the proportion, then vacuum smelt, the temperature of vacuum smelt is 760 ℃, in the process of vacuum smelting, feed a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com