Method for preparing few-layer Ti3C2Tx material with high etching rate and high stripping rate based on secondary etching method

A secondary etching and etching rate technology, applied in the field of 2D nanomaterials, can solve the problems of low stripping rate, long etching cycle, incomplete etching, etc., to achieve sufficient etching process, excellent product performance, and high stripping rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

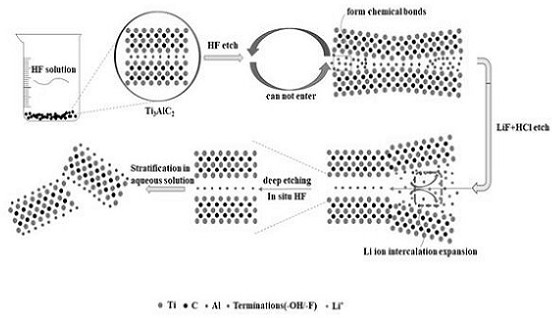

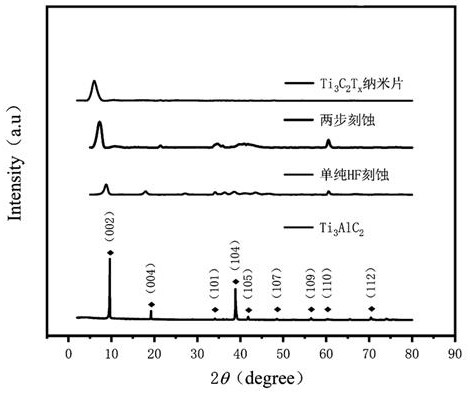

[0052] Preparation of Few-layer Ti with High Etching Rate and High Stripping Rate Based on Secondary Etching Method 3 C 2 T x The material method specifically includes the following steps:

[0053] (1) Weigh 1.0g Ti 3 AlC 2 Powder, slowly added to 12ml of HF aqueous solution with a mass fraction of 40%, the mixed solution was covered and placed in a fume hood, while stirring in a magnetic stirrer and warming up to 35°C, the magnetic stirrer speed was 500rpm, magnetic stirring for 4h Finally, centrifuge at 4000rpm for 10min, and wash with water several times until neutral to obtain the pre-etched product;

[0054] (2) Use a graduated cylinder to measure 10ml of HCl with a concentration of 3mol / L, and weigh 1.6g of LiF, slowly add LiF to the HCl solution, place the mixed solution in a magnetic stirrer at room temperature and stir for 15min, then magnetically stir The rotation speed of the device is 300rpm, and the mixed solution is used as a secondary etchant after the stir...

Embodiment 2

[0060] Preparation of Few-layer Ti with High Etching Rate and High Stripping Rate Based on Secondary Etching Method 3 C 2 T x The material method specifically includes the following steps:

[0061] Except that the concentration of HCl in (2) is 6mol / L;

[0062] (3) Medium magnetic stirring for 6 hours;

[0063] All the other are identical with embodiment 1.

[0064] After drying the upper suspension, 800 mg of few-layer Ti 3 C 2 T x , calculate Ti according to mass 3 C 2 T x The etch rate is 96%, few layers of Ti 3 C 2 T x The stripping rate is 80%.

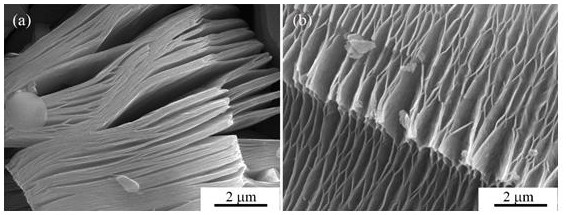

[0065] Figure 4 ( Figure 4 (a) and Figure 4 (b)) Preparation of the product few-layer Ti for Example 2 of the present invention 3 C 2 T x The TEM figure of material, as can be seen from the TEM result, the few-layer Ti that embodiment 2 makes 3 C 2 T x The sample still has an ultrathin two-dimensional layered structure, and the nanosheets have relatively large lateral dimensions, indicating that the few-l...

Embodiment 3

[0067] Preparation of Few-layer Ti with High Etching Rate and High Stripping Rate Based on Secondary Etching Method 3 C 2 T x The material method specifically includes the following steps:

[0068] Except that the concentration of HCl in (2) is 12mol / L;

[0069] (3) Medium magnetic stirring for 6 hours;

[0070] All the other are identical with embodiment 1.

[0071] After drying the upper suspension, 850 mg of few-layer Ti 3 C 2 T x , calculate Ti according to mass 3 C 2 T x The etch rate is 95%, few layers of Ti 3 C 2 T x The stripping rate is 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com