Treatment process for hydrazine hydrate wastewater

A technology for wastewater treatment and hydrazine hydrate, which is applied in water/sewage treatment, degassed water/sewage treatment, oxidized water/sewage treatment, etc. The problem of large amount of addition, to achieve the effect of simplifying the process, reducing the concentration of pollution, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

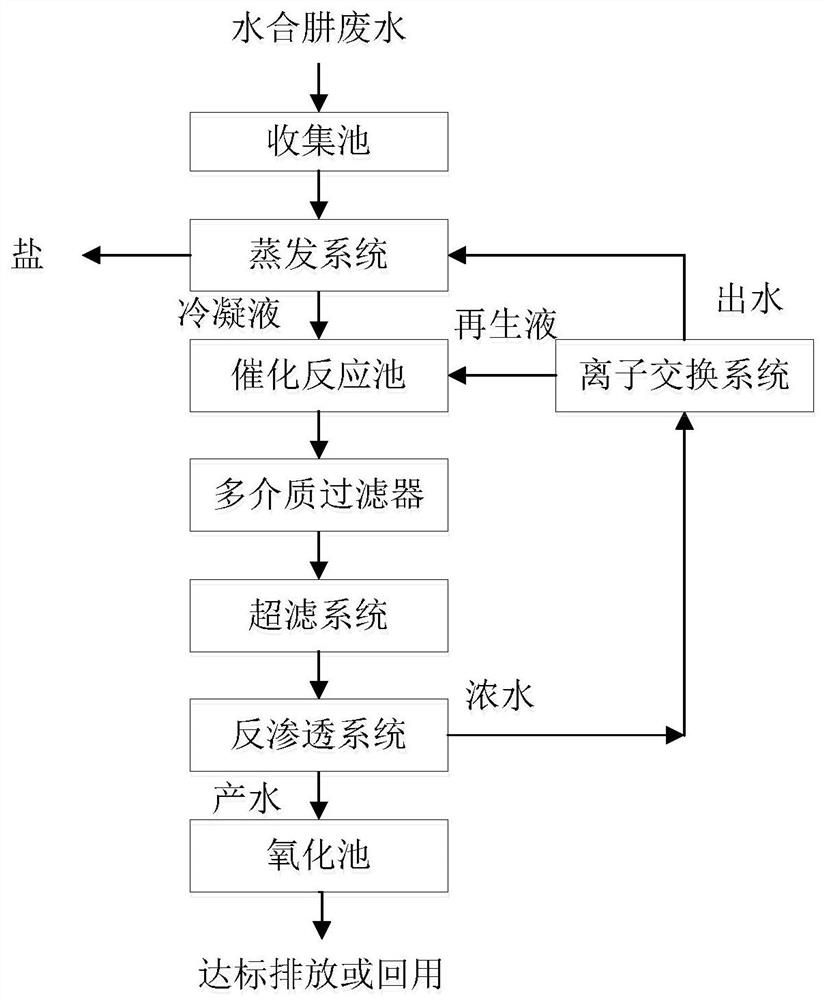

[0038] Step 1: collecting hydrazine hydrate wastewater;

[0039] Step 2: send the collected raw water of hydrazine hydrate wastewater into the evaporation system for evaporation, and collect the evaporation condensate; the salt evaporates and crystallizes, and is packaged and recovered after centrifugation;

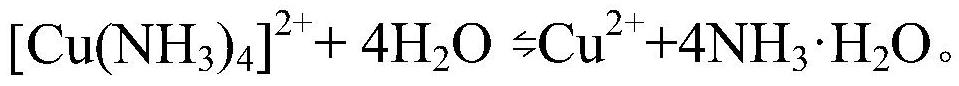

[0040] Step 3: discharge the condensate produced by evaporation into the catalytic reaction tank, add copper sulfate and aerate, the concentration of copper sulfate in the catalytic reaction tank is controlled at 0.4mmol / L, the pH is controlled between 6 and 9, and the residence time of wastewater is 40h;

[0041] Step 4: The effluent from the catalytic reaction tank passes through the multi-media filter, ultrafiltration system, and reverse osmosis system in sequence. The flow rate of the multi-media filter is 10m / h. The reverse osmosis system is arranged in two stages. The ratio is 2:1, the concentrated water in the first stage returns to the front of the high-pressure p...

Embodiment 2

[0048] The hydrazine hydrate wastewater treatment process provided by the present embodiment is basically the same as in Example 1, the difference is that:

[0049]1. The raw water in this embodiment is the condensate after MVR evaporation;

[0050] 2. In this example, the wastewater produced by reverse osmosis has reached the first-class standard, and there is no need to add an oxidant to oxidize;

[0051] Specific steps are as follows:

[0052] Step 1: The raw water is discharged into the catalytic reaction tank, copper sulfate is added and aerated, the concentration of copper sulfate in the catalytic reaction tank is controlled at 0.2mmol / L, the pH is controlled between 6 and 9, and the wastewater residence time is 24h;

[0053] Step 2: The effluent from the catalytic reaction tank passes through the multi-media filter, ultrafiltration system, and reverse osmosis system in sequence. The flow rate of the multi-media filter is 10m / h. The reverse osmosis system is arranged in...

Embodiment 2

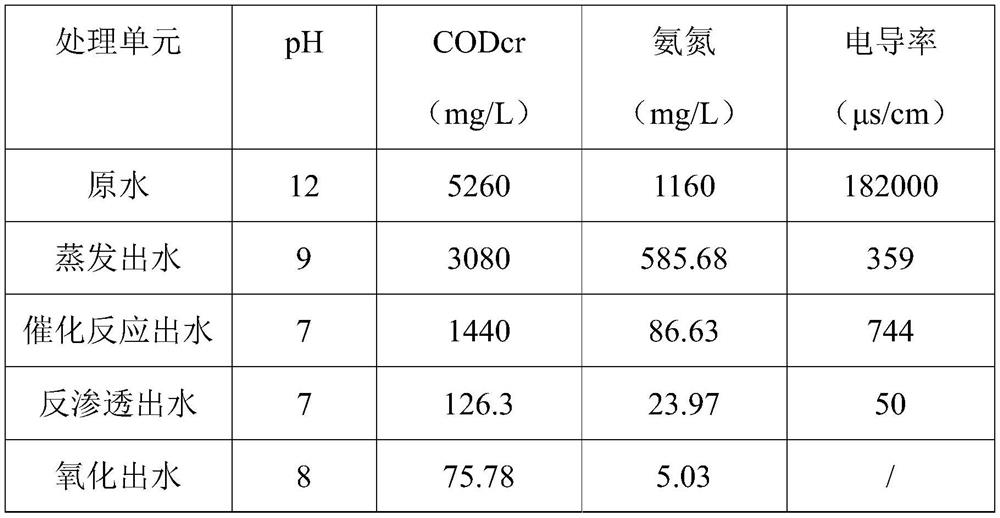

[0055] Embodiment 2 The effluent water quality of each main treatment unit is as follows:

[0056]

[0057] Comparing Example 1 and Example 2, it can be seen that when the CODcr and ammonia nitrogen indicators of the raw water are respectively 2400mg / L and 2300mg / L, the reverse osmosis effluent can reach the first-class standard. The CODcr and ammonia nitrogen indicators of the catalyzed reaction effluent in Examples 1 and 2 are significantly lower than those of the evaporated effluent, indicating that the copper salt has a good catalytic effect on the pollutants in the hydrazine hydrate wastewater.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com