Silicon carbide fireproof flame retardant coating for wood materials and preparation method thereof

A fire-retardant, wood-based material technology, used in fire-retardant coatings, coatings, epoxy resin coatings, etc., can solve the problem of insufficient bonding strength between the coating and the substrate, little improvement in the flame-retardant performance of the coating, and affecting the appearance of the substrate. And texture and other issues, to achieve good fire retardant, improve purity, improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

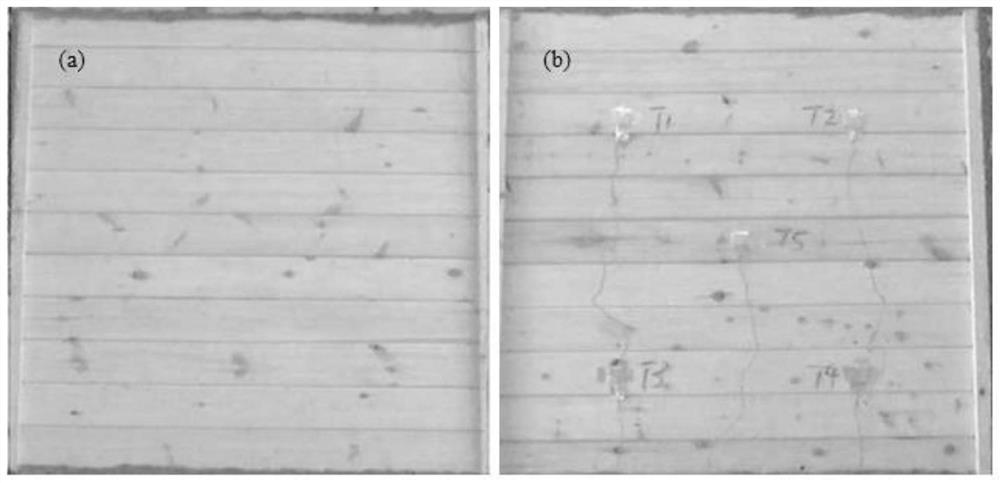

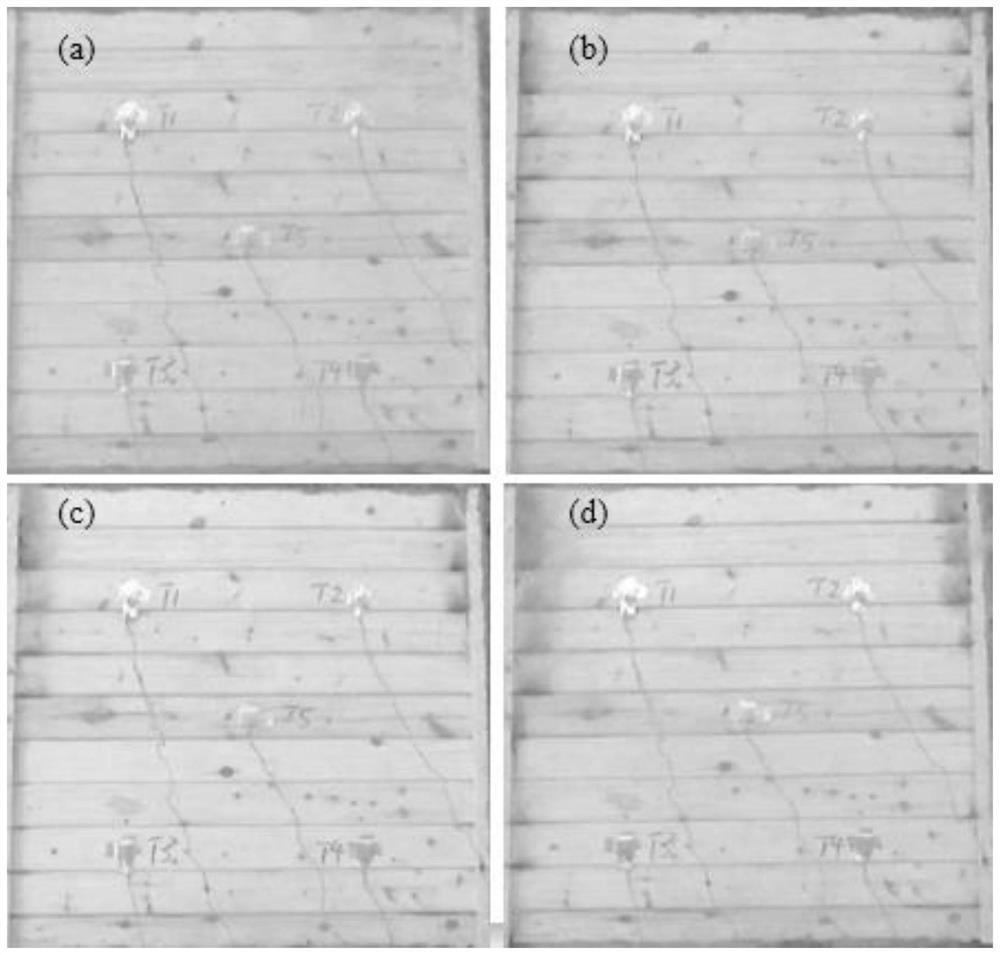

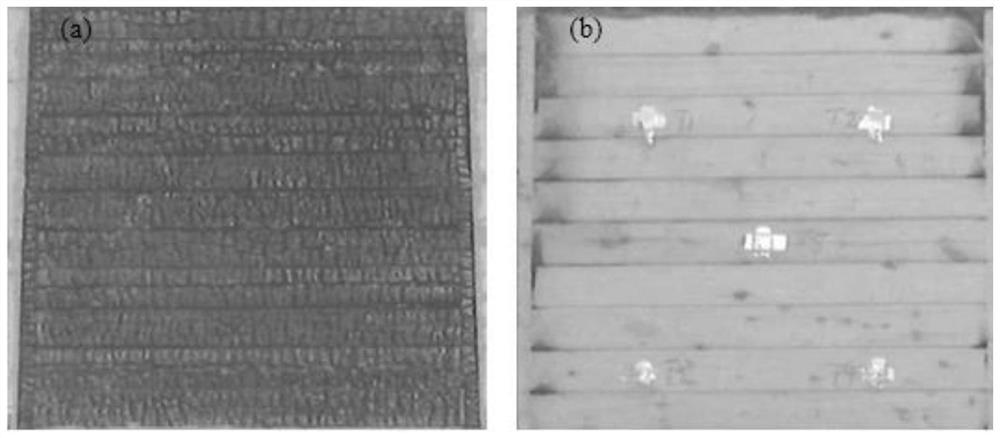

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a silicon carbide fireproof and flame retardant coating for wood materials, comprising the following steps:

[0033] S1. Adding nano-silicon carbide into hydrochloric acid solution, centrifuging, washing and drying successively after fully stirring, to obtain hydroxylated silicon carbide;

[0034] S2. After diethyl phosphite and carbon tetrachloride are uniformly mixed under ice-bath conditions, then add triethylenediamine and diethanolamine in turn, fully stir at room temperature until the reaction is complete, and obtain a clarified filtrate by filtration; Adding a predetermined amount of boric acid to the clarified filtrate, heating and stirring to make it fully react, to obtain a modified phosphoric acid ester;

[0035] S3. Mix the hydroxylated silicon carbide obtained in step S1 with the modified phosphate ester obtained in step S2, and heat and stir after ultrasonic dispersion to obtain a phosphate flame retardant graf...

Embodiment 1

[0044] This embodiment provides a method for preparing a silicon carbide fireproof and flame retardant coating for wood materials, comprising the following steps:

[0045] S1. Add 100g of nano-silicon carbide powder with a particle size of 50nm to 300mL of hydrochloric acid solution with a concentration of 2mol / L, stir at room temperature for 2h, then centrifuge, and wash the silicon carbide with deionized water until it is neutral, and then place it at 60 Dry at constant temperature for 24 hours at ℃ to obtain hydroxylated silicon carbide.

[0046] S2. After mixing 1 mol of diethyl phosphite and 1 mol of carbon tetrachloride, fully stir for 30 minutes under ice bath conditions, then add 1 mol of triethylenediamine and 1 mol of ethylene glycol amine in turn, and keep stirring at room temperature After reacting for 10 h, a solution containing a white solid was obtained; after filtering the solution, a clear filtrate was obtained. Then boric acid was added to the filtrate to ma...

Embodiment 2~7 and comparative example 1~2

[0058] Embodiments 2 to 7 and Comparative Examples 1 to 2 respectively provide a method for preparing a silicon carbide fireproof and flame retardant coating for wood materials. Compared with Example 1, the difference is that the phosphorous acid in step S2 is changed. The ratio of the amount of diethyl ester to the diethanolamine, the mass ratio of the clarified filtrate to boric acid or the temperature and time of heating and stirring, and the rest of the steps are consistent with Example 1, and will not be repeated here. The preparation parameters corresponding to each embodiment and comparative example are shown in Table 2.

[0059] Table 2 Relevant preparation parameters in Step S2 of Examples 2-7 and Comparative Examples 1-2

[0060]

[0061]

[0062] The peel strength and fire retardant properties of the fire retardant coatings prepared in Examples 2-7 and Comparative Examples 1-2 were tested, and the results are shown in Table 3.

[0063] Table 3 The performance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com