Special-shaped PBN-quartz combined crucible

A quartz crucible and crucible technology, applied in the field of semiconductor material production, can solve the problems of high dislocation density, easy cracking of substrates, low dislocation density, etc., and achieve the effects of low heat conduction efficiency, flat growth interface, low dislocation density and high dislocation density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with accompanying drawing:

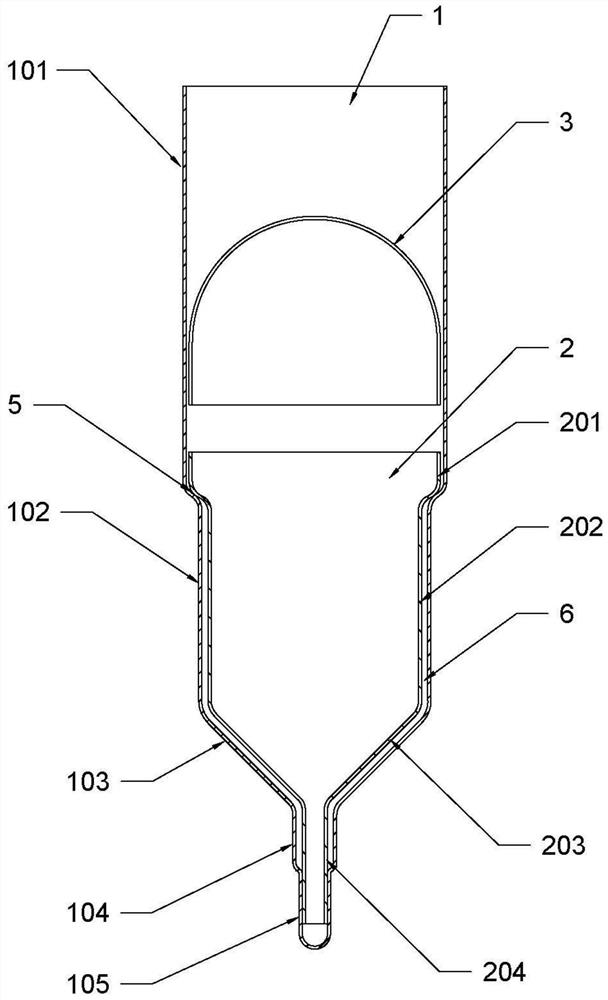

[0020] Such as figure 1 Shown:

[0021] A special-shaped PBN and quartz combined PBN crucible, including a quartz crucible 1, a PBN crucible 2 and a quartz cap 3, the PBN crucible 2 and the quartz cap 3 are both movable in the inner cavity of the quartz crucible 1; the quartz crucible 1 is from top to bottom Including the first quartz crucible section 101, the second quartz crucible section 102, the quartz crucible tapered section 103, the first seed crystal cavity section 104 and the second seed crystal cavity section 105 integrally formed in sequence, the first quartz crucible section 101, the second quartz crucible section The diameters of the two quartz crucible sections 102, the first seed crystal cavity section 104, and the second seed crystal cavity section 105 are successively reduced; the PBN crucible 2 includes sequentially integrally formed first PBN crucible ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com