A kind of preparation method of crystalline polyester and product thereof

A technology for crystalline polyester and products, applied in the field of preparation of crystalline polyester, can solve the problems of lack of efficient catalytic system reaction conditions, polymers not reported to have crystallinity, difficulty in copolymerizing isobutylene oxide, and the like, achieving no need for post-treatment Purification steps, rich variety, good universal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

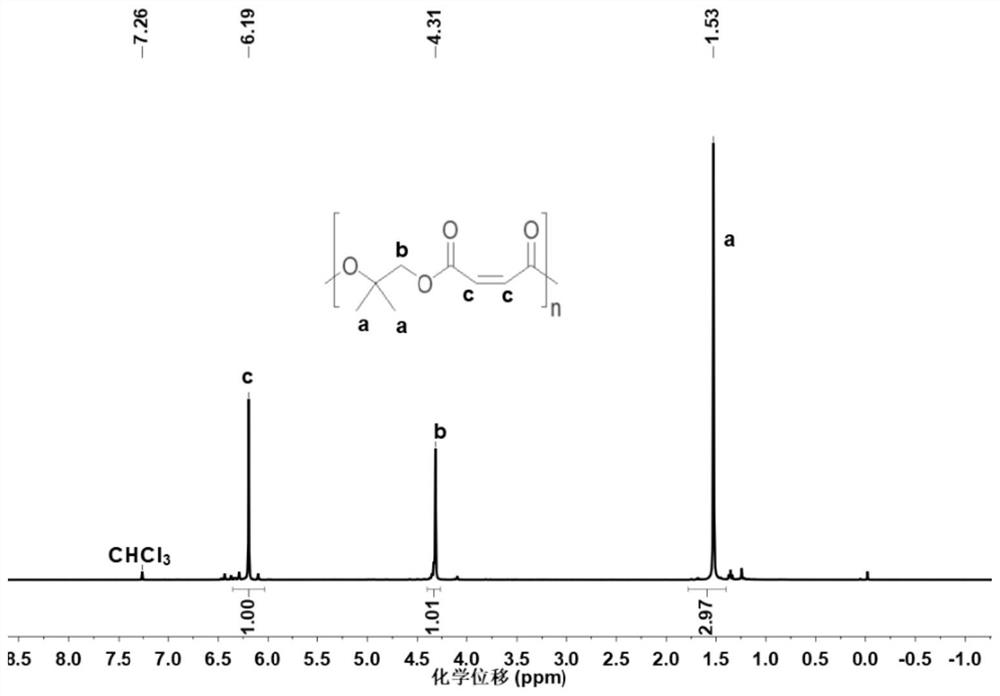

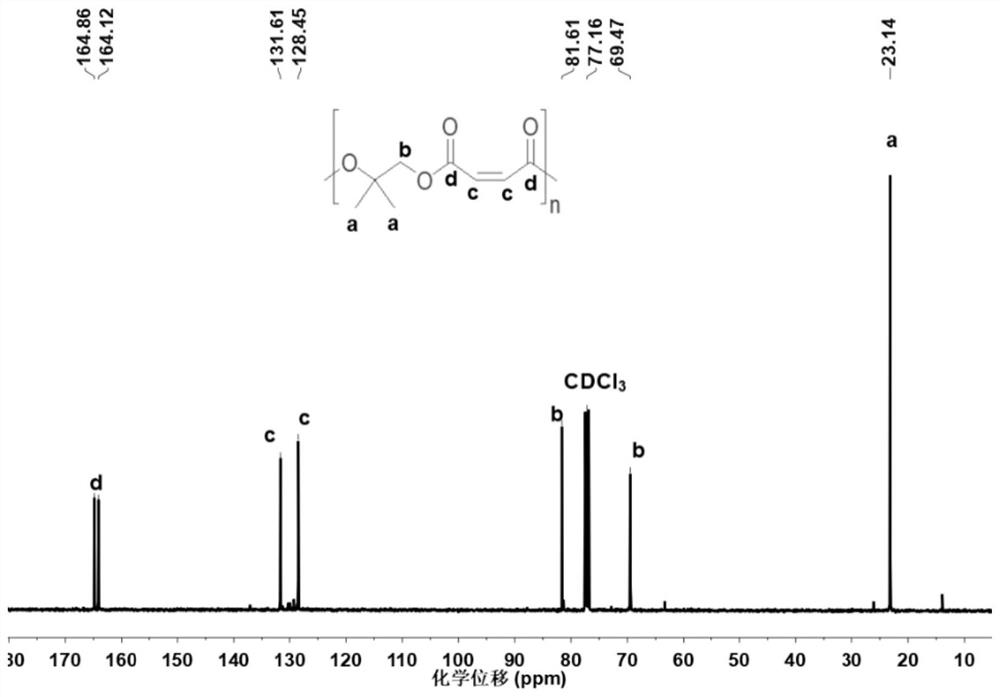

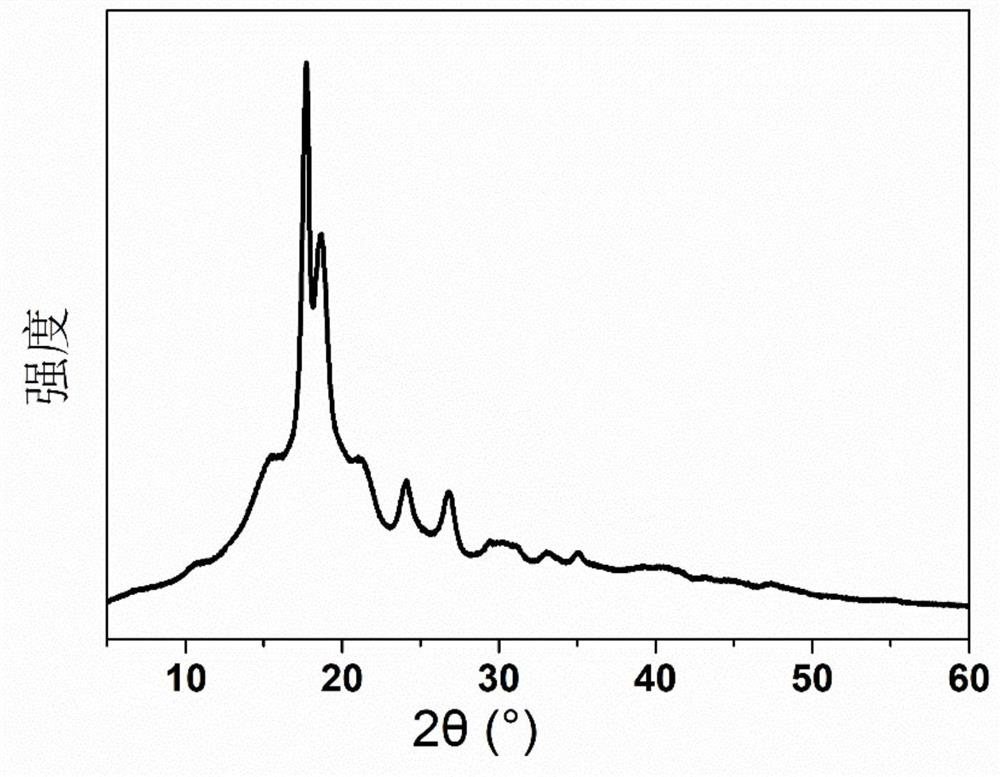

[0051] Embodiment 1 MA / IBO synthesizes oxidized isobutylene-based crystalline polyester

[0052] Before the polymerization reaction, put the 10mL reactor at 110°C for about 2 hours, remove the water and cool it to room temperature in a desiccator; add indium-cobalt double metal cyanide complex and maleic anhydride (MA) to the reactor in sequence , 1 mL of toluene and isobutylene oxide (IBO); the molar ratio of IBO to MA is 1:1, and the molar ratio of catalyst to IBO is 1 / 500. Then the reactor was closed and placed in an oil bath at 55°C for 12 hours under autogenous pressure. Cool to room temperature after the reaction, first dissolve the crude product with dichloromethane, then precipitate the polymer in ethanol, repeat washing three times, then soak the polymer in ethanol for 12 hours to induce crystallization, and vacuum-dry to constant weight. The molecular weight and molecular weight distribution of the polymer were determined by gel chromatography, and the test results ...

Embodiment 2

[0059] Embodiment 2 MA / IBO synthesizes oxidized isobutylene-based crystalline polyester

[0060] Before the polymerization reaction, the 10mL reaction kettle was dehydrated at 110°C for about 2 hours and cooled to room temperature in a desiccator; zinc-cobalt double metal cyanide complex, maleic anhydride (MA), 1 mL of toluene and isobutylene oxide (IBO); the molar ratio of IBO to MA is 1:1, and the molar ratio of catalyst to IBO is 1 / 500. Then the reactor was closed and placed in an oil bath at 55°C for 12 hours under autogenous pressure. Cool to room temperature after the reaction, first dissolve the crude product with dichloromethane, then precipitate the polymer in ethanol, repeat washing three times, then soak the polymer in methanol for 12 hours to induce crystallization, and vacuum-dry to constant weight. The molecular weight and molecular weight distribution of the polymer were determined by gel chromatography, and the test results are shown in Table 1.

[0061] Afte...

Embodiment 3

[0062] Embodiment 3 MA / IBO synthesizes oxidized isobutylene-based crystalline polyester

[0063] Before the polymerization reaction, the 10mL reaction kettle was dehydrated at 110°C for about 2 hours and cooled to room temperature in a desiccator; zinc-iron double metal cyanide complex, maleic anhydride (MA), 1 mL of toluene and isobutylene oxide (IBO); the molar ratio of IBO to MA is 1:1, and the molar ratio of catalyst to IBO is 1 / 500. Then the reactor was closed and placed in an oil bath at 55°C for 12 hours under autogenous pressure. Cool to room temperature after the reaction, first dissolve the crude product with dichloromethane, then precipitate the polymer in ethanol, repeat washing three times, then soak the polymer in methanol for 12 hours to induce crystallization, and vacuum-dry to constant weight. The molecular weight and molecular weight distribution of the polymer were determined by gel chromatography, and the test results are shown in Table 1.

[0064] After ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com