Green plum blossom fermented product for relieving gout

A fermented product, plum blossom technology, applied in the field of preparation of green plum blossom fermented products, can solve problems such as incomplete extraction and loss of active ingredients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

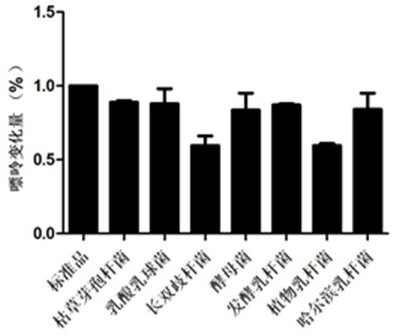

[0026] Screening of compound fermentation strains, liquid culture of Bacillus subtilis, Lactococcus lactis, Bifidobacterium longum, yeast, Lactobacillus fermentum, Lactobacillus plantarum, Lactobacillus harbin, until the bacterial activity of the strain reaches 1x10 11 when. Take 2ml of the bacterial solution and centrifuge at 5000r / min for 10min at 4°C to collect the bacterial cell pellet, and wash the bacterial cell with 1ml of PBS repeatedly for 3 times. Add 10mmol / L purine buffer solution to the cell pellet, incubate at 37°C for 30 minutes under anaerobic conditions, centrifuge to obtain the supernatant, and use high-performance liquid chromatography to detect the level of purine degradation by the strain.

[0027] Weigh 100g of the green plum blossom dry powder and crush it for 15 minutes with an ultrafine pulverizer, add 900ml of distilled water to the obtained green plum blossom dry powder, stir well, and adjust the pH to between 4.5-5.5.

[0028] 1 g of acid cellulase...

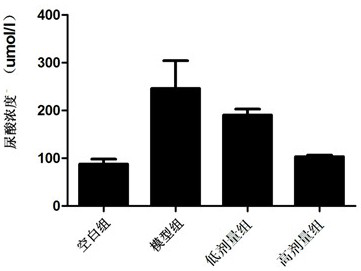

Embodiment 2

[0036] Weigh 150g of green plum blossom dry powder and crush it with an ultrafine pulverizer for 15 minutes, add 1350ml of distilled water to the obtained green plum blossom dry powder, stir well, and adjust the pH to between 4.5-5.5.

[0037] Add 1.5 g of acid cellulase and 1.5 g of acid protease while stirring, and stir for 2 hours for enzymolysis at 50° C.

[0038] Pasteurize the hydrolyzed solution at 85°C for 15 minutes, then inject 3L of sterile high-purity carbon dioxide gas into it, and then insert 3% Bifidobacterium longum and 3% Lactobacillus plantarum into it. After the inoculation was completed, they were cultured in an incubator at 37°C, and the pH and reducing sugar content were monitored every day. On the seventh day, it was detected that the pH and reducing sugar content did not change. The fermentation is over.

[0039] The fermented liquid was filtered to finally obtain 1200ml of clear liquid, and 0.06g of folic acid, 60g of isomalt, 24g of xylitol, 60g of m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com