Photocuring 3D printing preparation method of degradable meniscus scaffold

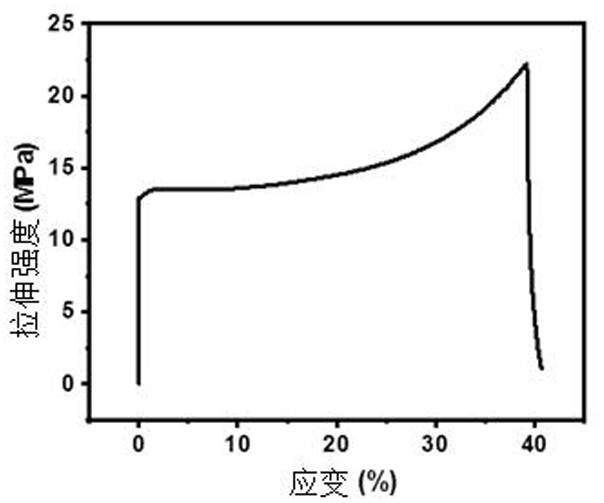

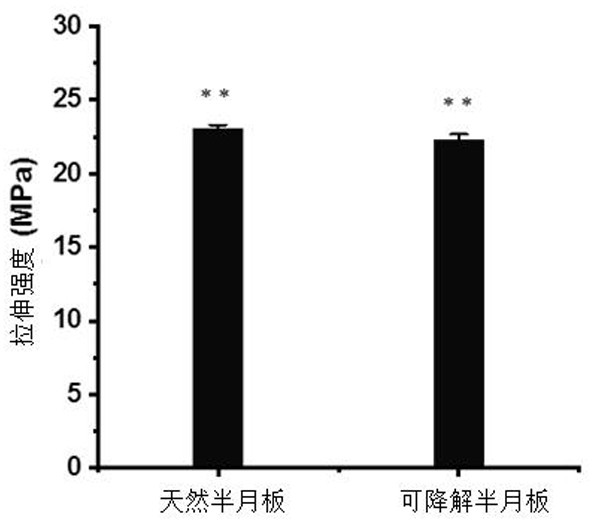

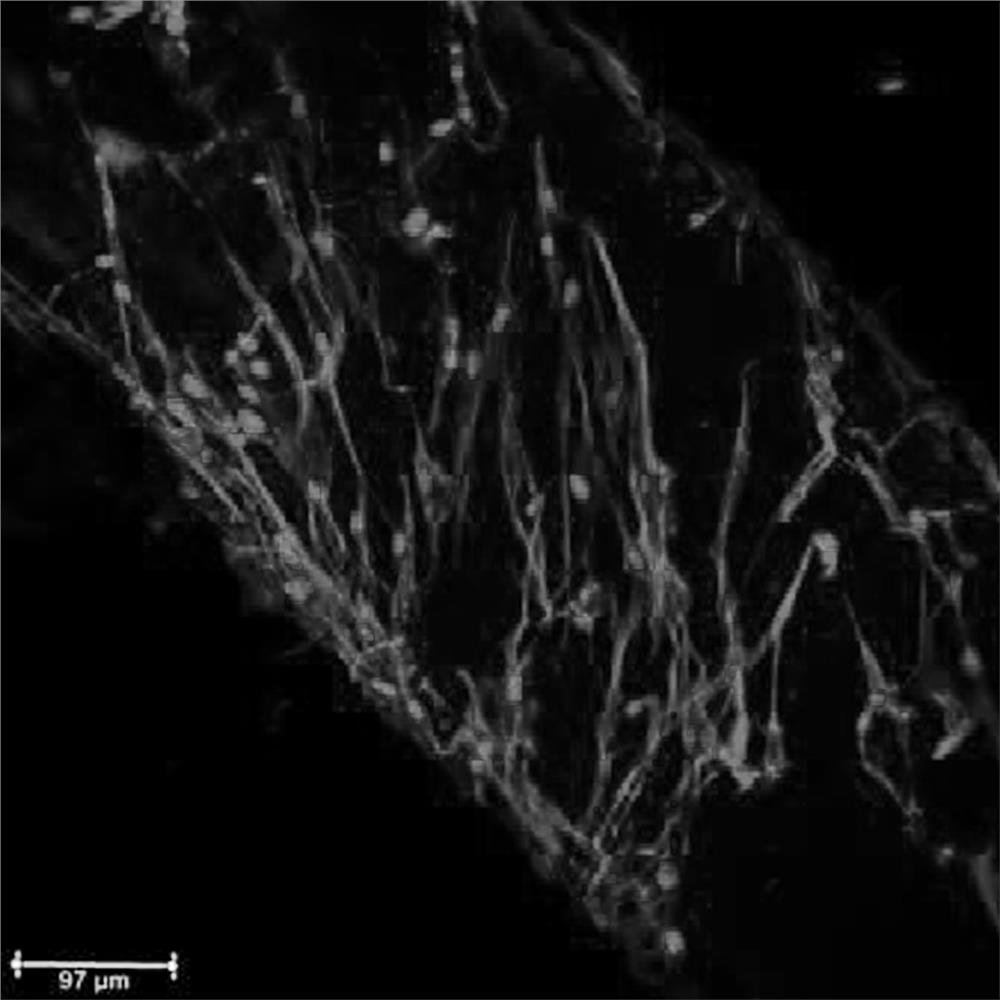

A 3D printing and meniscus technology, applied in medical science, prosthesis, additive processing, etc., can solve the problems of low printing accuracy, large difference in mechanical strength, and inability to achieve precise control of the meniscus structure, and achieve high printing accuracy. , good biocompatibility, no cytotoxic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] In a 250 mL round bottom flask equipped with mechanical stirring, nitrogen inlet tube, thermometer and dropping funnel, add 16.8 g of hexamethylene diisocyanate (HDI), and then add 20.0 g of polyethylene glycol diol (molecular weight 1000) and 90.0 g of polycaprolactone diol (molecular weight: 3000) were added dropwise into a three-necked flask, while maintaining the temperature of the reaction system in the flask at 50 °C. After the dropwise addition, the mixture continued to react for 2 h. The catalyst stannous octoate (600ppm of reactant mass) was added to the system to promote the reaction to fully occur. The degree of reaction was monitored by Fourier transform infrared, and when the characteristic infrared absorption peak of the isocyanate group no longer decreased, a mixture of 0.1 g of hydroquinone and 11.6 g of hydroxyethyl acrylate was added dropwise to the system, maintaining the temperature of the system at 80°C c. After the dropwise addition is completed,...

Embodiment 2

[0047] In a 250 mL round bottom flask equipped with mechanical stirring, nitrogen inlet tube, thermometer and dropping funnel, add 16.8 g of hexamethylene diisocyanate (HDI), and then add 40.0 g of polyethylene glycol diol (molecular weight 1000) and 90.0 g of polycaprolactone diol (molecular weight: 3000) were added dropwise into a three-necked flask, while maintaining the temperature of the reaction system in the flask at 80 °C. After the dropwise addition, the mixture continued to react for 14h. The catalyst stannous octoate (600ppm of reactant mass) was added to the system to promote the reaction to fully occur. The degree of reaction was monitored by Fourier transform infrared, and when the characteristic infrared absorption peak of the isocyanate group no longer decreased, a mixture of 0.1 g of hydroquinone and 7.0 g of hydroxyethyl acrylate was added dropwise to the system, maintaining the temperature of the system at 80°C c. After the dropwise addition is completed, ...

Embodiment 3

[0049] In a 250 mL round bottom flask equipped with mechanical stirring, nitrogen inlet tube, thermometer and dropping funnel, add 22.2 g of isophorone diisocyanate (IPDI), and then add 20.0 g of polyethylene glycol diol (molecular weight 1000) and 80.0 g of polycaprolactone diol (molecular weight: 4000) were added dropwise into a three-necked flask, while maintaining the temperature of the reaction system in the flask at 100 °C. After the dropwise addition, the mixture continued to react for 4 h. The catalyst stannous octoate (600 ppm of reactant mass) was added to the system to promote the reaction to take place fully. The degree of reaction was monitored by Fourier transform infrared, and when the characteristic infrared absorption peak of the isocyanate group no longer decreased, a mixture of 0.1 g of hydroquinone and 13.9 g of hydroxyethyl acrylate was added dropwise to the system, maintaining the temperature of the system at 50°C c. After the dropwise addition is compl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com