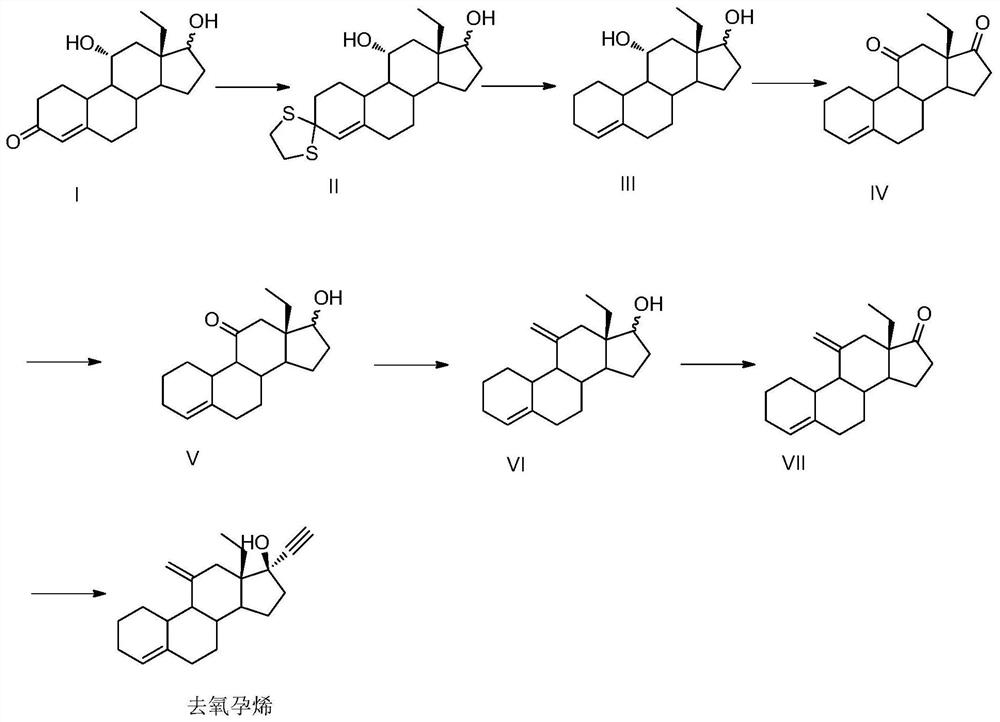

Preparation method of desogestrel key intermediate and preparation method of desogestrel

A desogestrel and intermediate technology, which is applied in the preparation of desogestrel key intermediates and in the field of desogestrel preparation, can solve problems such as product instability and easy decomposition, achieves good yield and purity, Not easy to decompose, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

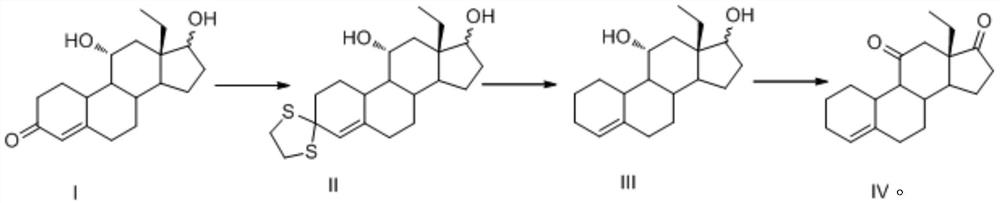

[0040] Embodiment 1 prepares intermediate II

[0041] Add 120 g of methanol to the three-neck flask, add 30 g of 11-hydroxyethyl nandrolone, adjust the temperature at 10-15° C., add 12 g of ethanedithiol, and stir for 10 minutes. Control the temperature at 10-15°C, add 9 mL of boron trifluoride diethyl ether solution dropwise into the reaction tank (the heat release is obvious during the dropwise addition), keep the reaction at 10-15°C for 1 hour and 15 minutes, and take samples for TLC detection until the raw material point disappears. After the reaction is complete, pour the reaction solution into 420mL ice water for water analysis, cool down to 0-5°C, stir for 30 minutes, filter, wash the filter cake with water until neutral, spin dry, and discharge the material, put the material in 40-50°C for drying After 12-16 hours, intermediate II was obtained. Yield: 100-110%.

Embodiment 2

[0042] Embodiment 2 prepares key intermediate III

[0043] In the three-necked flask II, cool down to -70°C, pass liquid ammonia, and stop flowing ammonia gas when the liquid ammonia reaches 500 mL. Weigh 6.5g of lithium metal, add it into the reaction flask three times at intervals of 10 minutes each time, control the inner temperature not to be higher than -50°C, and keep stirring for 2 hours after adding lithium. Add 250 mL of 50 g of intermediate II in tetrahydrofuran dropwise to the reaction flask, keep the internal temperature below -38.0° C., and drop for about 0.5 hours. After the dropwise addition, continue to insulate and stir the reaction for 1.5 hours to start spotting the plate, and TLC detects that the raw material spot disappears. After the reaction, slowly add 80 g of absolute ethanol dropwise to the reaction flask, control the internal temperature below -38.0°C during the dropwise addition, continue stirring for 20 minutes after the dropwise addition, and sto...

Embodiment 3

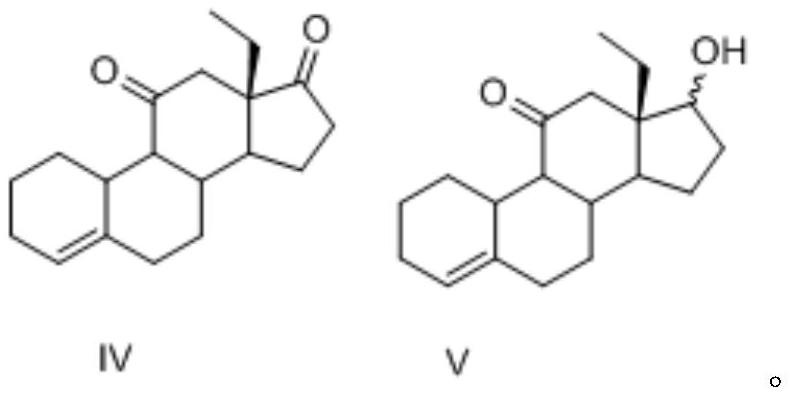

[0044] Embodiment 3 prepares intermediate IV

[0045] Add 350g of acetone and 20g of deketone into the three-necked flask. When the temperature drops to -15.0°C, start to add 19.6mL of Jones reagent dropwise. During the dropping process, the temperature is kept at -10.0~-15.0°C, and the dropping time is about 2 hours. After the dropwise addition, take a sampling plate until the raw material point disappears, add 20g of isopropanol at -10.0~-15.0°C for about 10 minutes, and stir for 10 minutes. Add 98mL of saturated sodium carbonate solution until the solution is slightly alkaline, pour the reaction solution into 600mL of ice water for water analysis, wash the filter cake until it is neutral, and dry it, and dry the material at a temperature of 30.0-35.0°C for 20 hours to obtain the intermediate IV, yield 80-90%. Purity ≥ 95.0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com