Gel-like descaling and derusting cleaning agent and preparation method thereof

A cleaning agent and gel technology, which is applied in the field of cleaning agents, can solve the problems of mildew, corrosion damage, and difficulty in cleaning on the surface of objects, and achieves the effects of simple preparation method, improved cleaning effect, and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

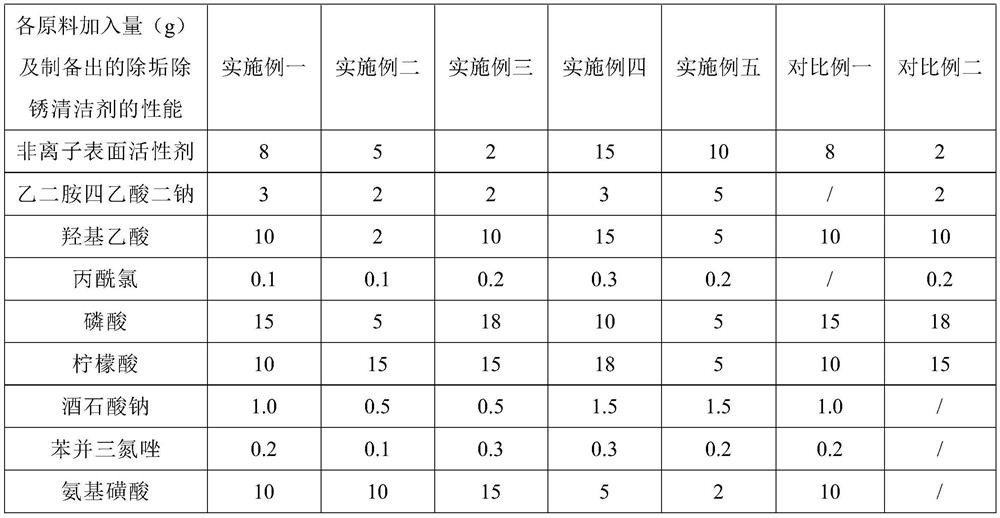

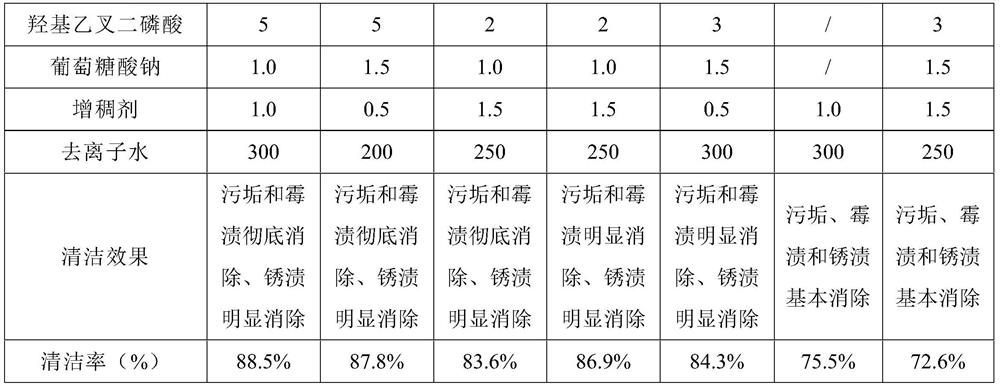

Examples

Embodiment 1

[0051] A preparation method of a jelly-like descaling and rust-removing cleaner, comprising the following steps:

[0052] (1) Heat deionized water to 55°C and add it to the reactor, then add nonionic surfactant to the reactor, lower the temperature in the reactor to normal temperature, then add disodium edetate, hydroxyl Acetic acid and propionyl chloride were stirred evenly, and left to stand for 15-20 minutes to obtain a mixed solution 1;

[0053] (2) Then add phosphoric acid, citric acid and sodium tartrate successively to mixed solution 1 to obtain mixed solution 2, and keep stirring during the addition process;

[0054] (3) Finally, mix benzotriazole, sulfamic acid, hydroxyethylidene diphosphate, sodium gluconate and a thickener, add it to the mixed solution 2, mix evenly, cool to room temperature, and pack.

[0055] Further, the thickener is acrylic acid.

[0056] Further, the plant fragrance is lavender extract.

[0057] Specifically, the nonionic surfactant is polyoxy...

Embodiment 2

[0059] A preparation method of a jelly-like descaling and rust-removing cleaner, comprising the following steps:

[0060] (1) Heat deionized water to 60°C and add it into the reaction kettle, then add nonionic surfactant into the reaction kettle, lower the temperature in the reaction kettle to normal temperature, then add disodium edetate, hydroxyl Acetic acid and propionyl chloride were stirred evenly, and left to stand for 15-20 minutes to obtain a mixed solution 1;

[0061] (2) Then add phosphoric acid, citric acid and sodium tartrate successively to mixed solution 1 to obtain mixed solution 2, and keep stirring during the addition process;

[0062] (3) Finally, mix benzotriazole, sulfamic acid, hydroxyethylidene diphosphate, sodium gluconate and a thickener, add it to the mixed solution 2, mix evenly, cool to room temperature, and pack.

[0063] Further, the thickener is acrylic acid.

[0064] Further, the plant fragrance is rose extract.

[0065] Specifically, the noni...

Embodiment 3

[0067] A preparation method of a jelly-like descaling and rust-removing cleaner, comprising the following steps:

[0068] (1) Heat deionized water to 58°C and add it to the reaction kettle, then add nonionic surfactant to the reaction kettle, lower the temperature in the reaction kettle to normal temperature, then add disodium edetate, hydroxyl Acetic acid and propionyl chloride were stirred evenly, and left to stand for 15-20 minutes to obtain a mixed solution 1;

[0069] (2) Then add phosphoric acid, citric acid and sodium tartrate successively to mixed solution 1 to obtain mixed solution 2, and keep stirring during the addition process;

[0070] (3) Finally, mix benzotriazole, sulfamic acid, hydroxyethylidene diphosphate, sodium gluconate and a thickener, add it to the mixed solution 2, mix evenly, cool to room temperature, and pack.

[0071] Further, the thickener is acrylate.

[0072] Further, the plant fragrance is peppermint extract.

[0073] Specifically, the nonion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com