A kind of in-situ ultrafine grain TIC reinforced titanium matrix composite material based on cyclohexene ball milling medium and its preparation method

A technology of titanium-based composite material and ball milling medium, which is applied in the field of non-ferrous metal processing, can solve the problems of high energy consumption, low utilization rate of cast titanium products, and reduced alloy plasticity, and achieves reduction of raw material costs, rapid and efficient preparation, and cost savings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

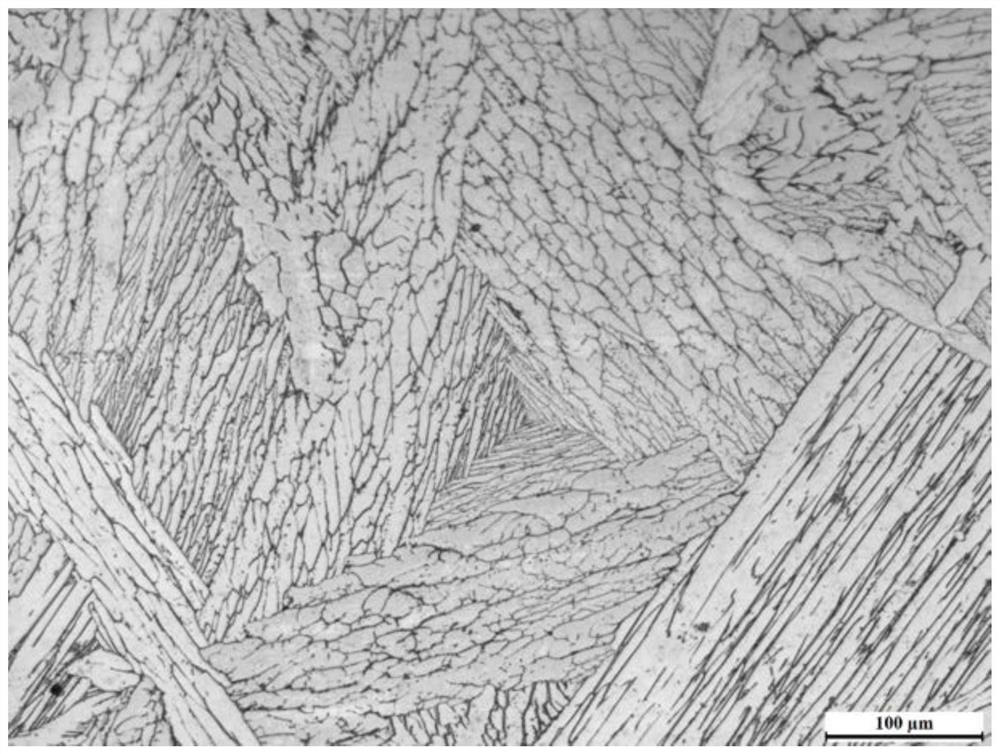

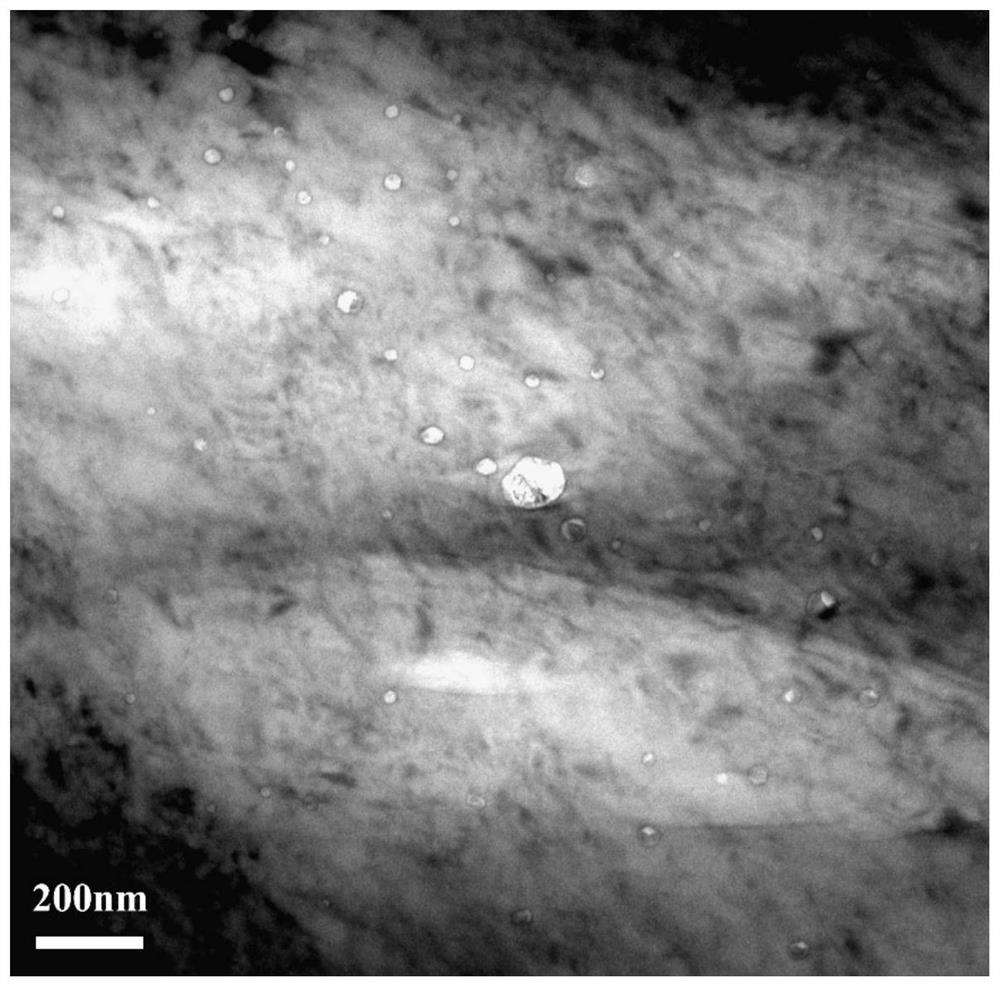

[0042] A method for preparing in-situ ultrafine-grained TiC reinforced titanium-based composite materials based on cyclohexene ball milling media, comprising the following steps:

[0043] The raw materials used in this example are as follows: 60Al40V powder (particle size 25 μm), titanium hydride powder (particle size 75 μm), pure Ti powder (particle size 45 μm), cyclohexene.

[0044] (1) Preparation of composite powder by high-energy ball milling: 100 parts by mass of 60Al40V and 20 parts by mass of Ti powder were weighed and mixed in a powder mixer at a speed of 300 rpm for 12 hours. Then pour the uniformly mixed powder and 40 parts by volume of cyclohexene into a planetary ball mill (QM-2SP20) stainless steel ball milling tank. The diameters of the selected stainless steel balls are 15mm, 10mm and 6mm respectively, and the mass ratio is 1:3:1. The ball milling parameters are as follows: the atmosphere is 1 atmosphere of high-purity argon (99.999%), the ball-to-material rati...

Embodiment 2

[0049] A method for preparing in-situ ultrafine-grained TiC reinforced titanium-based composite materials based on cyclohexene ball milling media, comprising the following steps:

[0050] The raw materials used in this example are as follows: 60Al40V powder (particle size 25 μm), titanium hydride powder (particle size 75 μm), pure Ti powder (particle size 45 μm), cyclohexene.

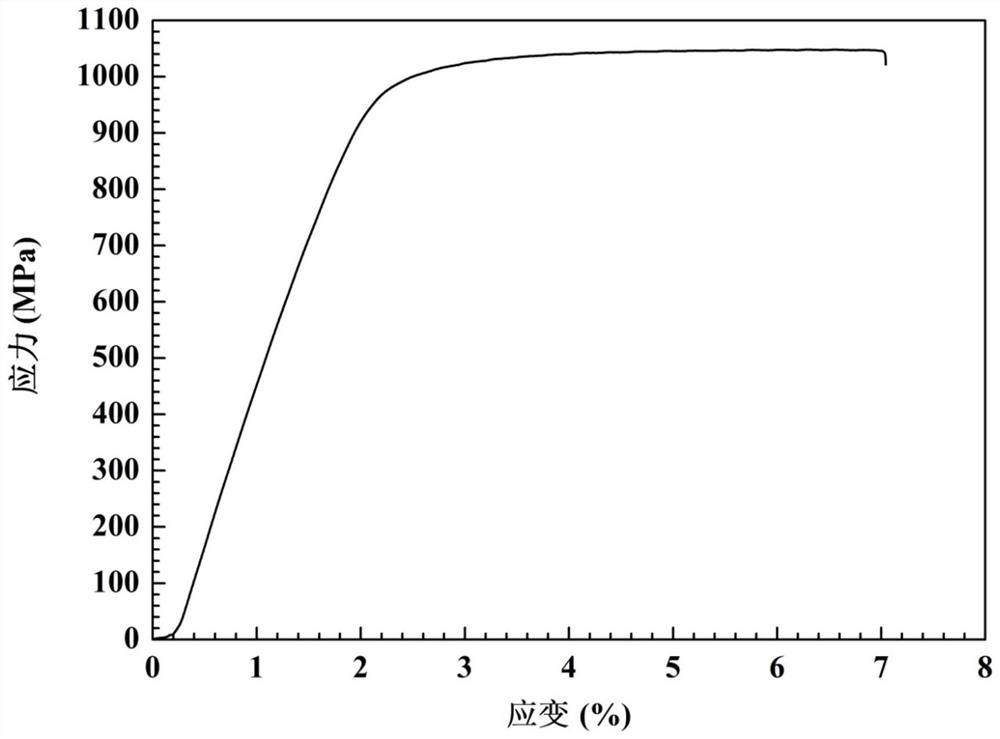

[0051] (1) Design of TiC content: Ti-6Al-4V is selected as the alloy in this embodiment. First, the TiC content in the design target product is 3vol.%, and the mass fraction of TiC in the composite material can be calculated as 3.3wt.% according to the formula (1):

[0052]

[0053] Among them, i v To design the TiC volume fraction in the target product, ρ TiC TiC density (4.93g / cm 3 ), ρ M is the density of the selected matrix alloy. Then 10 parts by mass of 60Al40V required by 100 parts by mass of Ti6Al4V composite material requires 3.3 parts by mass of TiC. According to the amount of TiC gen...

Embodiment 3

[0058] A method for preparing in-situ ultrafine-grained TiC reinforced titanium-based composite materials based on cyclohexene ball milling media, comprising the following steps:

[0059] The raw materials used in this example are as follows: vanadium powder (45 μm), iron powder (45 μm), aluminum powder (25 μm), titanium hydride powder (75 μm), pure titanium powder (45 μm), and cyclohexene.

[0060] (1) TiC content design: the alloy selected in this embodiment is Ti-10V-2Fe-3Al. First, design the mass of TiC to be 1vol.%, and calculate the mass fraction of TiC in the composite material to be 1.05% according to the formula (1). Then 100 parts by mass of the Ti-10V-2Fe-3Al composite material requires 15 parts by mass of 10V-2Fe-3Al and 1.05 parts by mass of TiC. According to the amount of TiC generated: the amount of Ti added is 0.8825 and the mass of Ti required for calculation is 1.19 parts by mass. Then the mass ratio of 10V-2Fe-3Al to Ti is 15:1.19. According to the mass ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com