A kind of phenolic resin composition test and quantitative analysis method and application

A technology of phenolic resin and analytical method, which is applied in the field of quantitative measurement, can solve the problems of little difference in molecular volume, the test efficiency needs to be improved, and the separation efficiency of chromatographic columns is difficult, so as to achieve the effect of easy analysis, fast detection speed and intuitive spectrum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

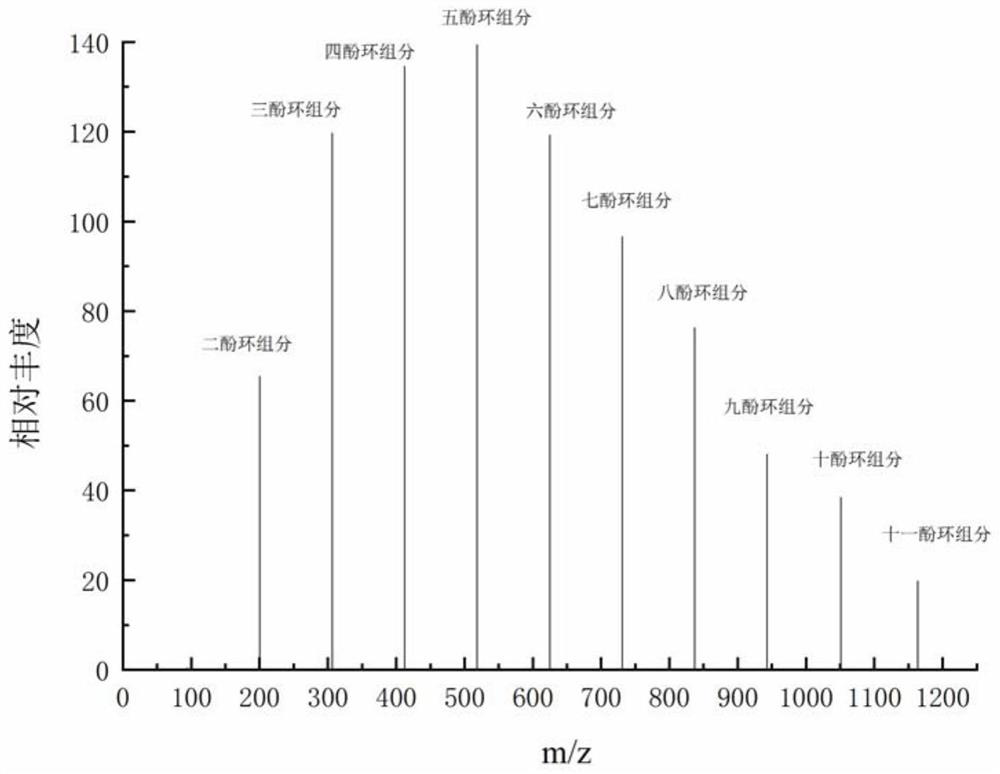

[0062] Thermoplastic phenolic resin (purchased from Jinan Shengquan Group Co., Ltd., brand PF-8020, softening point is 105-109 ° C) sample FD-MS spectrum determination and component characteristics, relative content of each component and average molecular weight calculate.

[0063] (1) Preparation of test samples

[0064] Take a PF-8020 resin sample and place it in a sample bottle, dry it in an oven at 105°C for 30 minutes to remove the absorbed moisture, and grind it into a fine powder after cooling in the dryer. Take chromatographically pure tetrahydrofuran (THF), measure 10mL, add to the sample dissolving bottle; weigh 200mg of PF-8020 powder sample, dissolve it in the above 10mL THF, sonicate the sample to completely dissolve, and prepare a solution with a concentration of 20mg / mL ,stand-by.

[0065] (2) FD-MS spectrum test

[0066] The German Thermo Fisher DFS high-resolution double-focusing magnetic mass spectrometer was used to test the PF-8020 resin FD-MS spectrum. ...

Embodiment 2

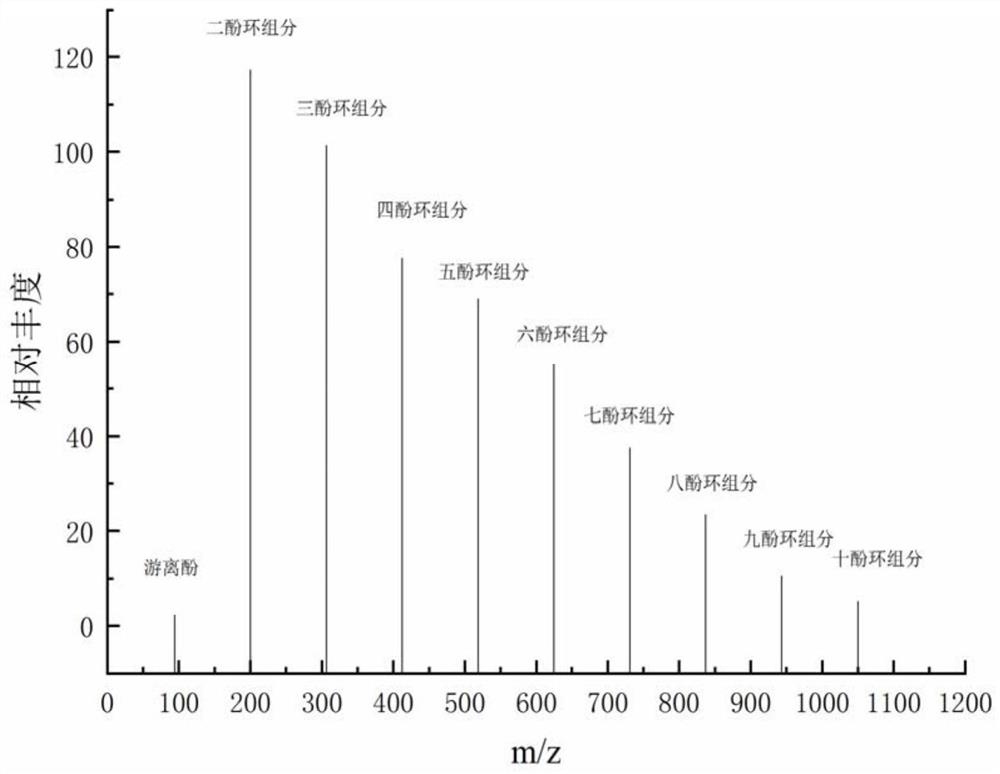

[0076] Determination of FD-MS spectrum of a sample of thermoplastic phenolic resin (purchased from Jinan Shengquan Group Co., Ltd., brand PF-8013, softening point 89-94°C) and its component characteristics, relative content of each component and calculation of average molecular weight .

[0077] (1) Preparation of test samples

[0078] Take the PF-8013 resin sample and place it in a sample bottle, dry it in an oven at 105°C for 30 minutes to remove the absorbed moisture, and grind it into a fine powder after cooling in the dryer. Take chromatographically pure N,N-dimethylformamide (DMF), measure 10mL, and add it to the sample dissolution bottle; weigh 250mg of PF-8013 powder sample, dissolve it in the above 10mL THF, sonicate the sample to completely dissolve, and prepare into a solution with a concentration of 25 mg / mL for use.

[0079] (2) FD-MS spectrum test

[0080] The PF-8013 resin FD-MS spectrum was tested by a German Thermo Fisher DFS high-resolution double-focusing...

Embodiment 3

[0090] Determination of the FD-MS spectrum of the high-purity phenolic resin sample (softening point 80-85°C) made by the Institute of Chemistry, Chinese Academy of Sciences, and the calculation of its component characteristics, relative content of each component and average molecular weight.

[0091] (1) Preparation of homemade thermoplastic high-purity phenolic resin

[0092] Take 94.11 grams of phenol, 64.04 grams of formaldehyde and 1.58 grams of oxalic acid, put them into a 250mL three-necked flask equipped with a mechanical stirrer, a thermometer and a condenser, and stir for 10 minutes to mix the materials evenly; use an oil bath to heat the above reaction materials, and after 30 minutes The temperature was raised to 70°C, and the temperature was kept for 1.5 hours, and the temperature was further raised to 85°C, and the temperature was continued for 2 hours. After the reaction was completed, deionized water was added, washed with water until neutral, and the water laye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com