Amorphous carbon-silicon-carbon nanofiber-graphite composite material as well as preparation method and application thereof

A carbon nanofiber, composite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., to achieve the effect of avoiding residue, avoiding repeated formation and destruction, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

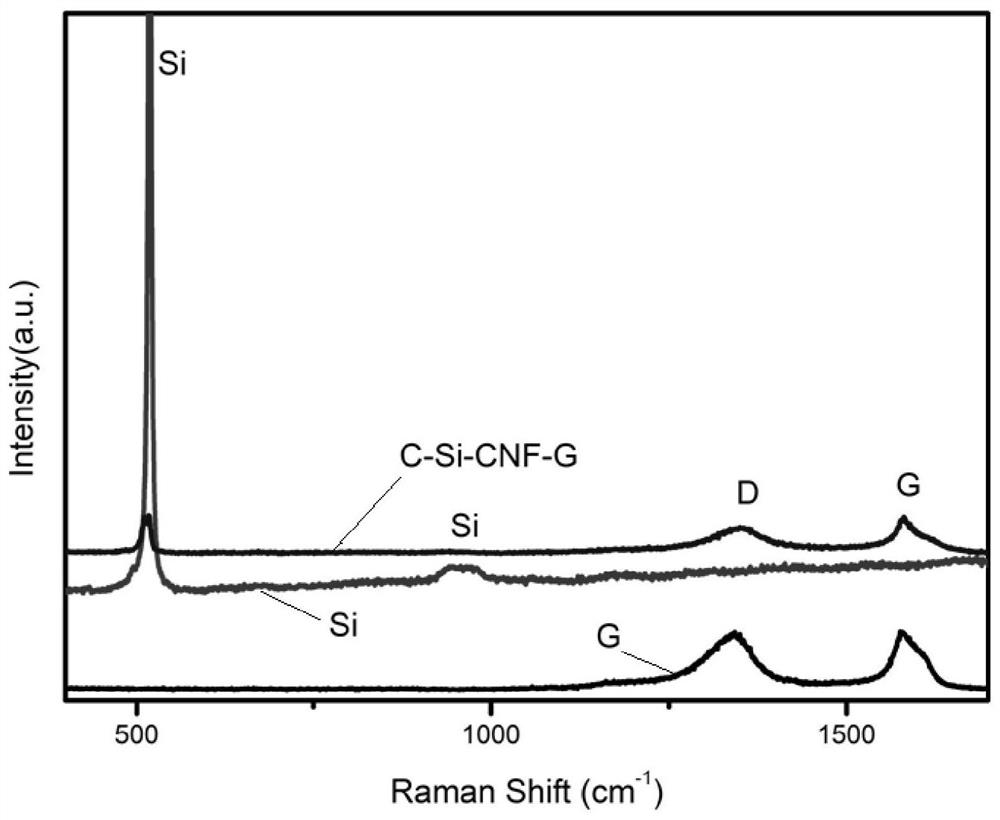

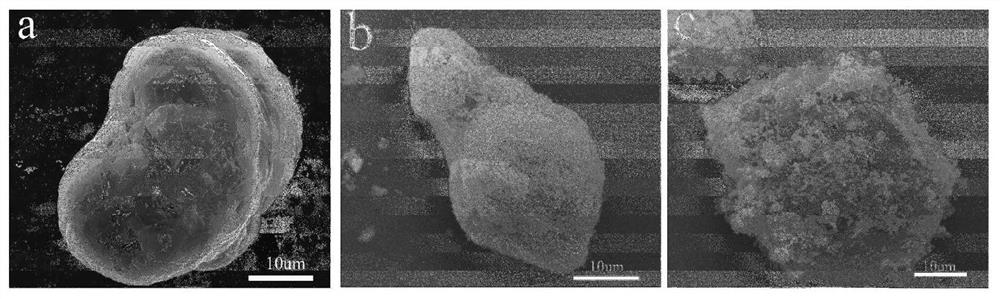

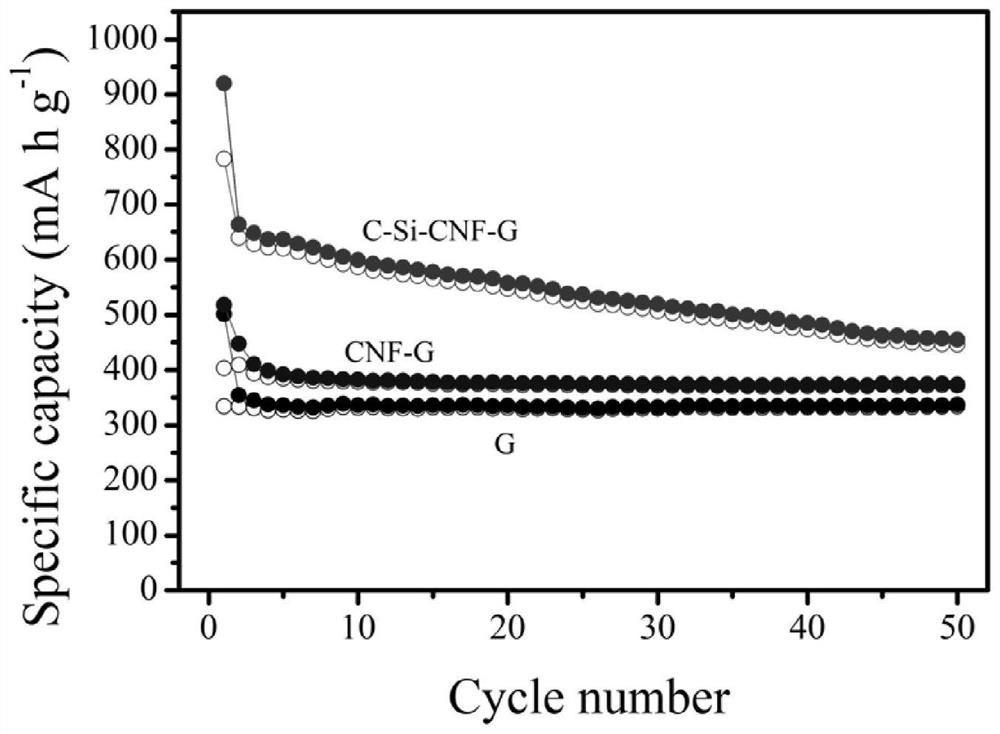

[0032]1. Weigh 50g of graphite powder and 2g of ferric chloride and mix them in an aqueous solution, dry them in a blast drying oven at 80°C for 12 hours, grind them, and sieve them through a 200-mesh sieve. Take the above sample and place it in a chemical vapor deposition furnace, use methane as the carbon source, deposit it under the condition of 800 degrees Celsius and normal pressure for 0.5h, and then place it in a high-temperature furnace for 0.5h at 1500 degrees Celsius to remove trace elements to prepare carbon nanofiber-natural stone Ink Composite.

[0033] 2. Take 5g of sample 1 and put it into a specific tooling and place it in a chemical vapor deposition furnace. Use dichlorodimethylsilane as the silicon source and argon as the carrier gas. Deposit at 900 degrees Celsius for 2 hours. The deposited sample is ground and then removed. Washing with deionized water three times, suction filtration and drying, the silicon-carbon nanofiber-natural graphite composite materi...

Embodiment 2

[0040] 1. Weigh 50g of graphite powder and 2g of nickel nitrate, mix them in an aqueous solution, dry them in a blast drying oven at 80°C for 12h, grind them, and sieve them through a 200-mesh sieve. Take the above sample and place it in a chemical vapor deposition furnace, use propylene as the carbon source, deposit it at 900 degrees Celsius under normal pressure for 0.5 hours, and then place it in a high-temperature furnace for 0.5 hours at 1500 degrees Celsius to remove trace elements to prepare carbon nanofiber-natural stone Ink Composite.

[0041] 2. Take 5g of sample 1 and place it in a specific tooling and place it in a chemical vapor deposition furnace. Use dichlorodimethylsilane as the silicon source and argon as the carrier gas. Deposit at 900 degrees Celsius for 1 hour. The deposited sample is ground and then removed. Washing with deionized water three times, suction filtration and drying, the silicon-carbon nanofiber-natural graphite composite material was prepared...

Embodiment 3

[0045] 1. Weigh 50g of graphite powder and 2g of cobalt nitrate, mix them in an aqueous solution, dry them in a blast drying oven at 80 degrees Celsius for 12 hours, grind them, and sieve them through a 200-mesh sieve. Take the above sample and place it in a chemical vapor deposition furnace, use propylene as the carbon source, deposit it at 800 degrees Celsius and normal pressure for 0.5 hours, and then place it in a high-temperature furnace for 0.5 hours at 1500 degrees Celsius to remove trace elements to prepare carbon nanofiber-natural stone Ink composite negative electrode wiping material.

[0046] 2. Take 5g of sample 1 and put it into a specific tooling and place it in a chemical vapor deposition furnace. Use dichlorodimethylsilane as the silicon source and argon as the carrier gas. Deposit at 900 degrees Celsius for 2 hours. The deposited sample is ground and then removed. Washing with deionized water three times, suction filtering and drying, the silicon-carbon nanofi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com