Flotation inhibitor for separating fine stibnite from pyrite and application of flotation inhibitor

A technology of stibnite and pyrite, which is applied in the field of flotation inhibitors, can solve the problem of unsatisfactory separation of fine-grained stibnite and pyrite, difficulty in effectively separating stibnite and pyrite, and stibnite Limited grade improvement and other issues, to achieve the effects of high cost, enhanced selective suppression, and large environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

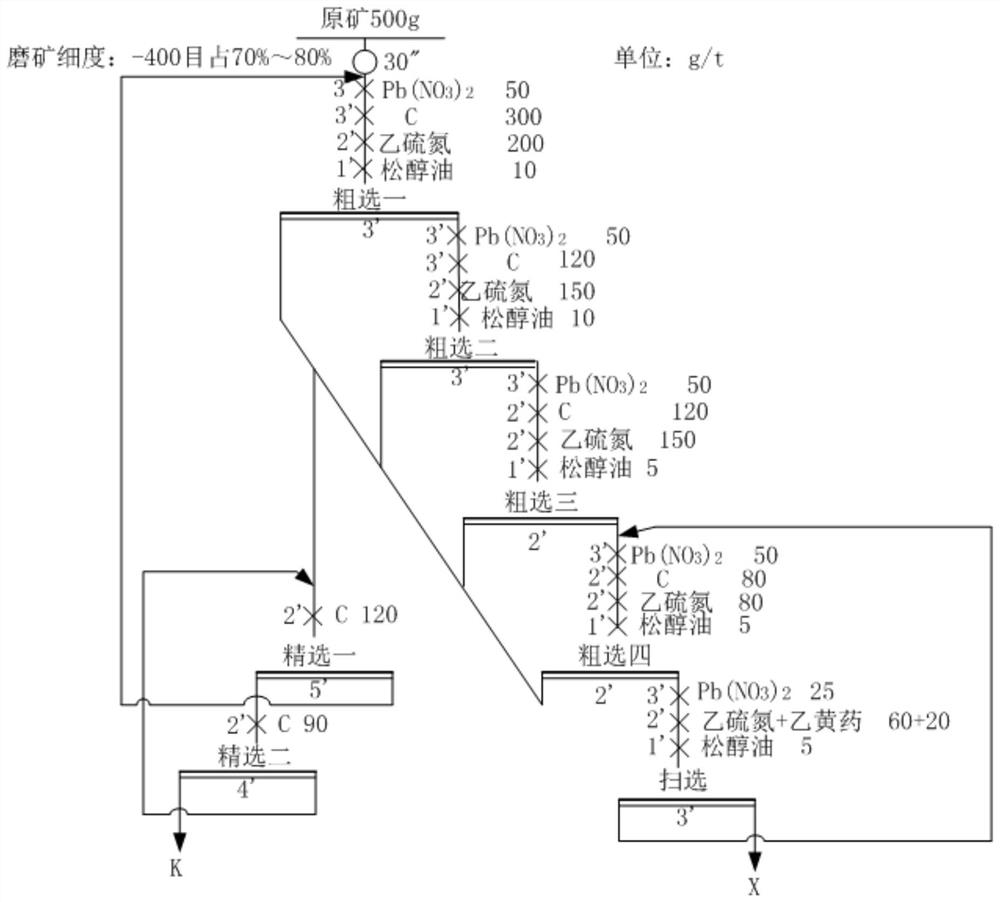

[0032] A certain fine-grained stibnite in Hunan was recovered by adopting the present invention. The raw ore is a sulfide ore product enriched by preliminary flotation, with fine-grained stibnite and pyrite as the main components, and -400 mesh accounts for about 70%, of which the raw ore antimony grade is 31.72%, Fe grade is 4.52%, and yellow The particle size of iron ore and stibnite is fine, and part of stibnite and pyrite have not been dissociated, and there are chemical residues on the surface of the mineral, so the separation is difficult.

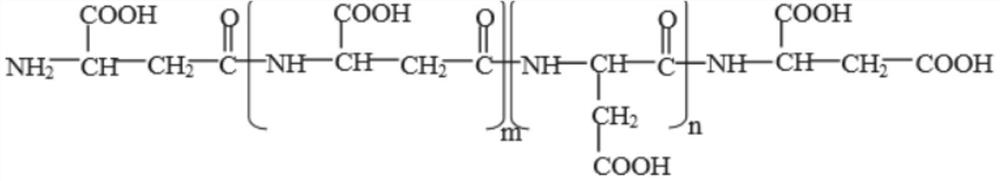

[0033] Raw ore adopts four times of roughing, one sweeping and two beneficiation processes to recover stibnite. Grind the raw ore to -400 mesh, accounting for 70-80%, and obtain the rough concentrate of stibnite through four times of "starvation flotation", that is, roughing one: add 50 g / t of lead nitrate, stir for 3 minutes; add 300 g / t flotation inhibitor C, stirring for 3 minutes; adding 200 g / t of ethionyl nitrogen, stirring fo...

Embodiment 2

[0073] A certain fine-grained stibnite in Hunan was recovered by adopting the present invention. The raw ore is a sulfide ore product enriched by preliminary flotation, with fine-grained stibnite and pyrite as the main components, and -400 mesh accounts for about 75%, of which the raw ore antimony grade is 32.42%, Fe grade is 4.68%, yellow The particle size of iron ore and stibnite is fine, and part of stibnite and pyrite have not been dissociated, and there are chemical residues on the surface of the mineral, so the separation is difficult.

[0074] Raw ore adopts four times of roughing, one sweeping and two beneficiation processes to recover stibnite. Grind the raw ore to -400 mesh, accounting for 70-80%, and obtain the rough concentrate of stibnite through four times of "starvation flotation", that is, roughing one: add 65 g / t lead nitrate, stir for 3 minutes; add 400 g / t flotation inhibitor C, stirring for 3 minutes; adding 100 g / t of ethionyl nitrogen, stirring for 2 min...

Embodiment 3

[0082] A certain fine-grained stibnite in Hunan was recovered by adopting the present invention. The raw ore is a sulfide ore product enriched by preliminary flotation, with fine-grained stibnite and pyrite as the main components, and -400 mesh accounts for about 75%, of which the raw ore antimony grade is 32.57%, Fe grade is 4.95%, yellow The particle size of iron ore and stibnite is fine, and part of stibnite and pyrite have not been dissociated, and there are chemical residues on the surface of the mineral, so the separation is difficult.

[0083] Raw ore adopts four times of roughing, one sweeping and two beneficiation processes to recover stibnite. Grind the raw ore to -400 mesh, accounting for 70-80%, and obtain the rough concentrate of stibnite through four times of "starvation flotation", that is, roughing one: add 65 g / t lead nitrate, stir for 3 minutes; add 200 g / t flotation inhibitor C, stirring for 3 minutes; adding 100 g / t of ethionyl nitrogen, stirring for 2 min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com