Method for slowing down deposition of gallium nitride on pipe wall in halide vapor phase epitaxial growth system and halide vapor phase epitaxial growth system

A vapor phase epitaxy, halide technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve problems affecting GaN epitaxial growth rate, uniformity and quality, blocking, reducing GaCl concentration and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

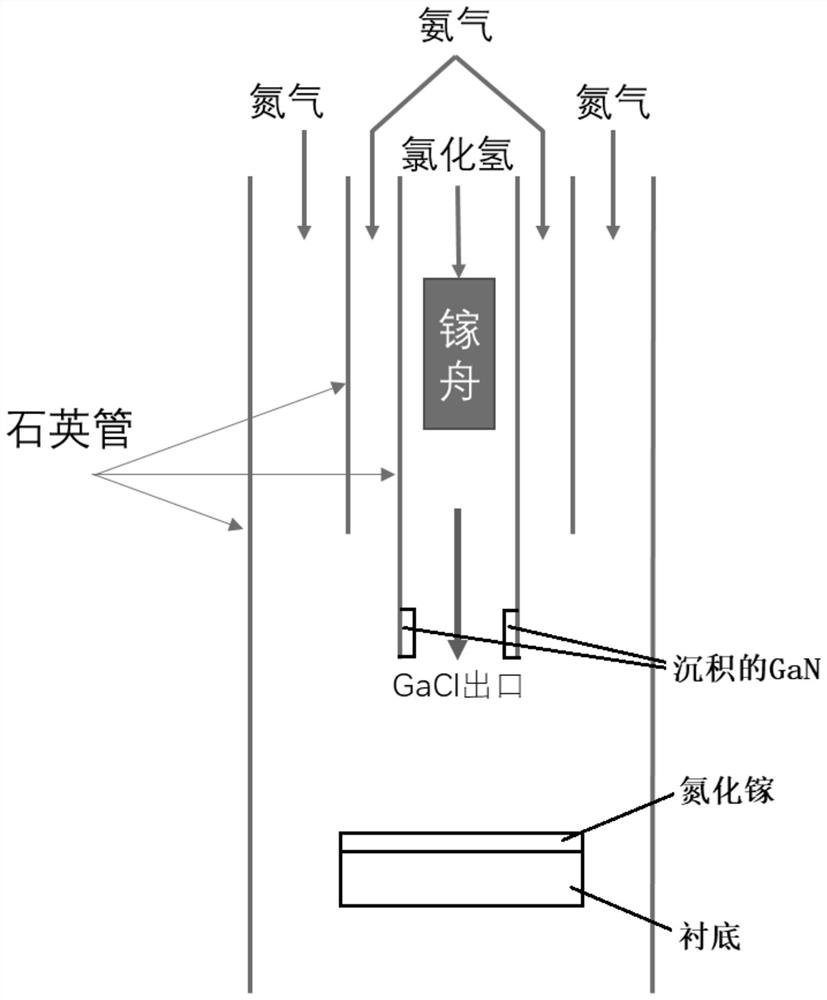

Problems solved by technology

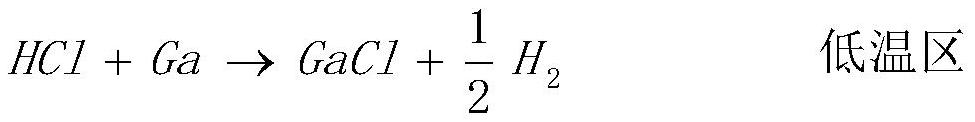

Method used

Image

Examples

Embodiment 1

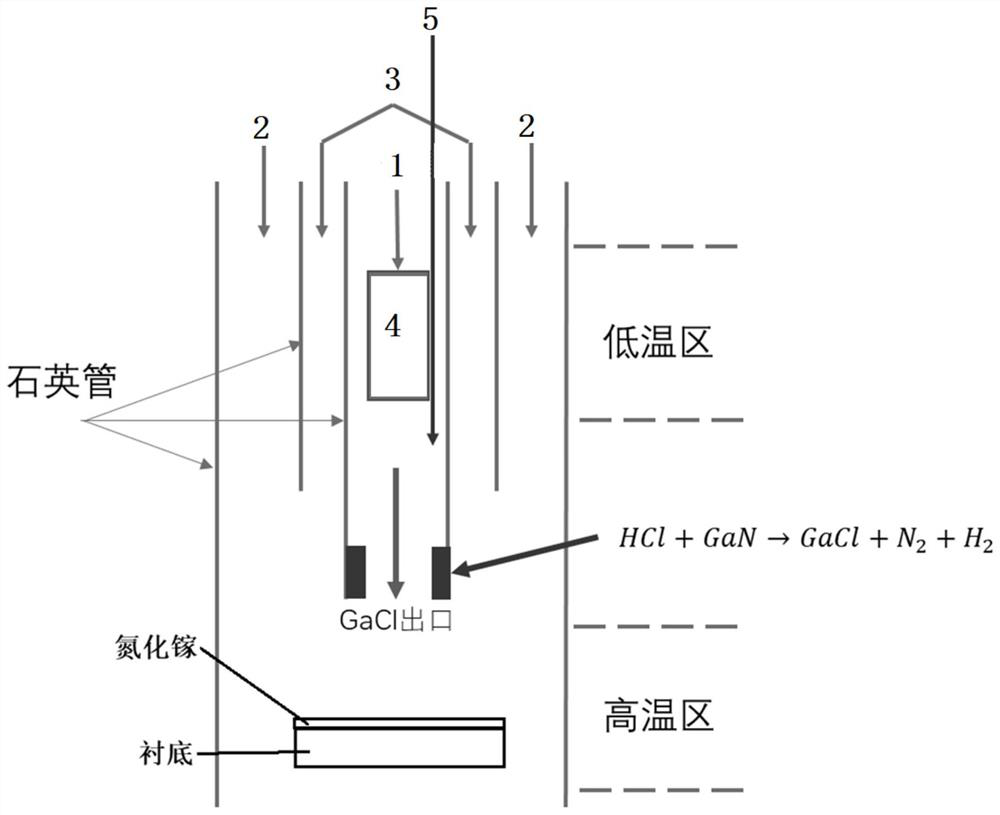

[0023] A halide vapor phase epitaxial growth system, including a growth area and a gas path system, wherein the gas path system includes a first HCl conduit 1, N 2 Conduit 2 and NH 3 The conduit 3, the first HCl conduit 1 leading to the gallium boat 4, is characterized in that it also includes a second HCl conduit 5 leading to a position close to the GaCl outlet.

Embodiment 2

[0025] A method for slowing down deposition of gallium nitride on tube walls in a halide vapor phase epitaxial growth system, the steps comprising:

[0026] 1. Cleaning and processing of sapphire substrate.

[0027] 2. After the sapphire substrate is placed in the reactor, the temperature is slowly raised to the growth temperature, and the GaN growth can begin. The growth temperature is 1100°C. Gas flow respectively: NH 3 The flow rate is 1500sccm, NH 3 The carrier gas flow is 1000 sccm, the HCl flow of the first HCl conduit 1 is 20 sccm, the HCl carrier gas flow is 500 sccm, the corrosion HCl flow of the second HCl conduit 5 is 5 sccm, and its carrier gas is 500 sccm. The total nitrogen is 15000 sccm. The sample is a 2-inch sapphire substrate. The reaction chamber pressure is 1 atmosphere.

[0028] 3. After growing to a suitable time, slowly cool down to room temperature at a certain rate, and take out the sample. In this embodiment, the growth time is about 60 minutes...

Embodiment 3

[0031] A method for slowing down deposition of gallium nitride on tube walls in a halide vapor phase epitaxial growth system, the steps comprising:

[0032] 1. Cleaning and processing of sapphire substrate.

[0033] 2. After the sapphire substrate is placed in the reactor, the temperature is slowly raised to the growth temperature, and the GaN growth can begin. The growth temperature is 1050°C. Gas flow respectively: NH 3 The flow rate is 1500sccm, NH 3 The carrier gas flow is 1000 sccm, the HCl flow of the first HCl conduit 1 is 20 sccm, the HCl carrier gas flow is 500 sccm, the corrosion HCl flow of the second HCl conduit 5 is 10 sccm, and its carrier gas is 500 sccm. The total nitrogen is 15000 sccm. The sample is a 2-inch sapphire substrate. The reaction chamber pressure is 1 atmosphere.

[0034] 3. After growing to a suitable time, slowly cool down to room temperature at a certain rate, and take out the sample. In this embodiment, the growth time is about 60 minute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com