A kind of silicon etchant for removing grain

A technology of etching solution and deionized water, which is applied in the direction of surface etching composition, chemical instrument and method, etc., can solve the problems of unsatisfactory mechanical grinding sheet etching, difficult control of etching rate, uneven etching surface, etc., so as to omit polishing Effects of degraining process, increasing solubility, and increasing etching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 provides a kind of degrinding etchant and etching result, specifically:

[0030] The weight content of nitric acid is 5%; the weight content of hydroxylamine nitrate is 0.3%; the weight content of fluorosulfonic acid is 0.6%; the weight content of ammonium bifluoride is 6%; The weight content is 82%; the weight content of polyacrylamide is 0.05%; the weight content of deionized water is the balance.

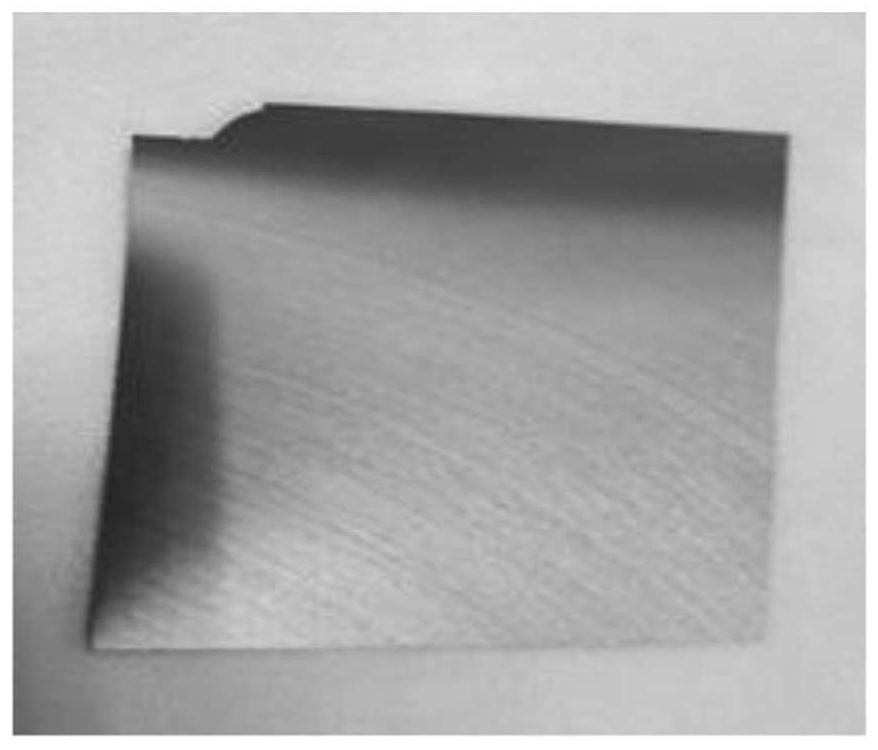

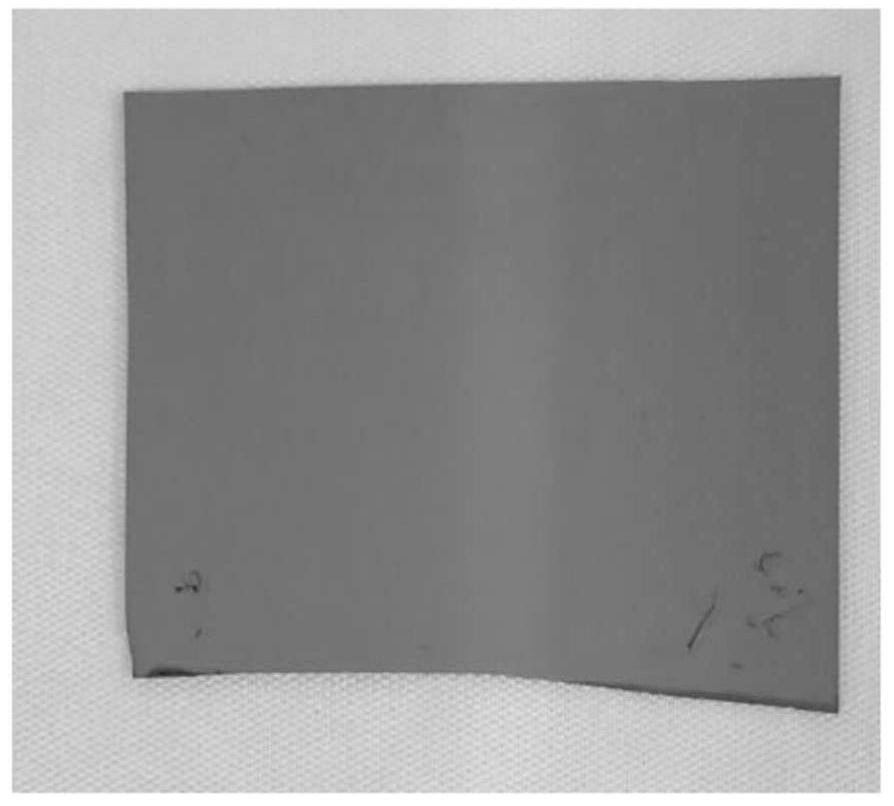

[0031] The above-mentioned silicon etching solution for removing abrasive grains was subjected to an etching experiment on a mechanically polished wafer (3cm×3cm) at 25°C. The etching method was rotary spray etching, and the etching time was 1min. The silicon wafer before and after etching was detected by a spiral micrometer. The thickness, and calculate etching rate, etching rate=(H 1 -H 2 ) / t, and use a surface roughness meter to detect the Roughness, Ra1, Ra2 of the surface before and after etching, and observe the removal of the surface wear lines with t...

Embodiment 2

[0035]A kind of anti-grain etching solution and etching result, specifically: the weight content of nitric acid is 6%; the weight content of hydroxylamine nitrate is 0.5%; the weight content of fluorosulfonic acid is 1%; the weight content of ammonium bifluoride is 5% The weight content of xenon difluoride is 2%; the weight content of sulfuric acid is 80%; the weight content of polyethylene glycol is 0.1%; the weight content of deionized water is the balance.

[0036] The detection means of etching effect is the same as that of Example 1, and the etching effect is recorded in Table 1.

Embodiment 3

[0038] A kind of anti-grind etching solution and etching result, specifically: the weight content of nitric acid is 5%; the weight content of hydroxylamine nitrate is 0.5%; the weight content of fluorosulfonic acid is 0.4%; The weight content of xenon difluoride is 0.5%; the weight content of sulfuric acid is 82%; the weight content of polyacrylamide is 0.03%; the weight content of deionized water is the balance.

[0039] The detection means of etching effect is the same as that of Example 1, and the etching effect is recorded in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com