Preparation method and application of copper-cobalt oxide loaded carbon nanofiber composite material

A technology of carbon nanofibers and composite materials, which is applied in the field of catalysis, can solve problems such as the reduction of catalytic efficiency, achieve the effects of accelerating reaction rate, increasing specific surface area, and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing a carbon nanofiber composite material loaded with copper-cobalt oxide in this embodiment comprises the following steps:

[0041] Step 1. Synthesize the electrospinning solution by heating and stirring

[0042]The specific operation is: first, 0.25 moL of Cu(NO 3 ) 2 ·3H 2 O and 0.5 moL of Co(NO 3 ) 2 ·6H 2 O was dissolved in 13.5 mL of deionized water and stirred evenly; then 0.5 g of cetyltrimethylammonium bromide (CTAB) was added and heated to 40 °C and the solution was stirred until transparent pink, indicating that the metal salt and surfactant CTAB was completely dissolved; finally, 1.5 g of polyvinyl alcohol (PVA) was slowly poured into the above mixed solution, and stirred at a constant temperature of 85 °C for 5 h; after natural cooling, the beaker was taken out and stirred slowly at room temperature overnight, marked as CuCo- PVA aqueous solution, standby;

[0043] Step 2. High-voltage electrospinning

[0044] First, wrap clean ti...

Embodiment 2

[0048] The preparation method of a carbon nanofiber composite material loaded with copper cobalt oxide in this embodiment is the same as that in embodiment 1, the difference is that

[0049] In step 1, only Cu(NO 3 ) 2 ·3H 2 The amount of O was 0.75 mol to obtain a CuO catalyst.

Embodiment 3

[0051] The preparation method of a carbon nanofiber composite material loaded with copper cobalt oxide in this embodiment is the same as that in embodiment 1, the difference is that

[0052] In step 1, only Co(NO 3 ) 2 ·6H 2 The amount of O was 0.75 moL to obtain Co 3 o 4 catalyst.

[0053] The following describes the performance test of the carbon nanofiber composite material in the embodiment of the present invention with reference to the accompanying drawings.

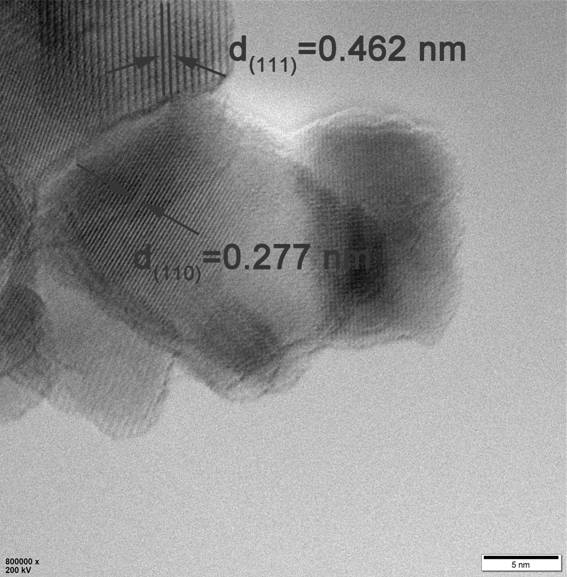

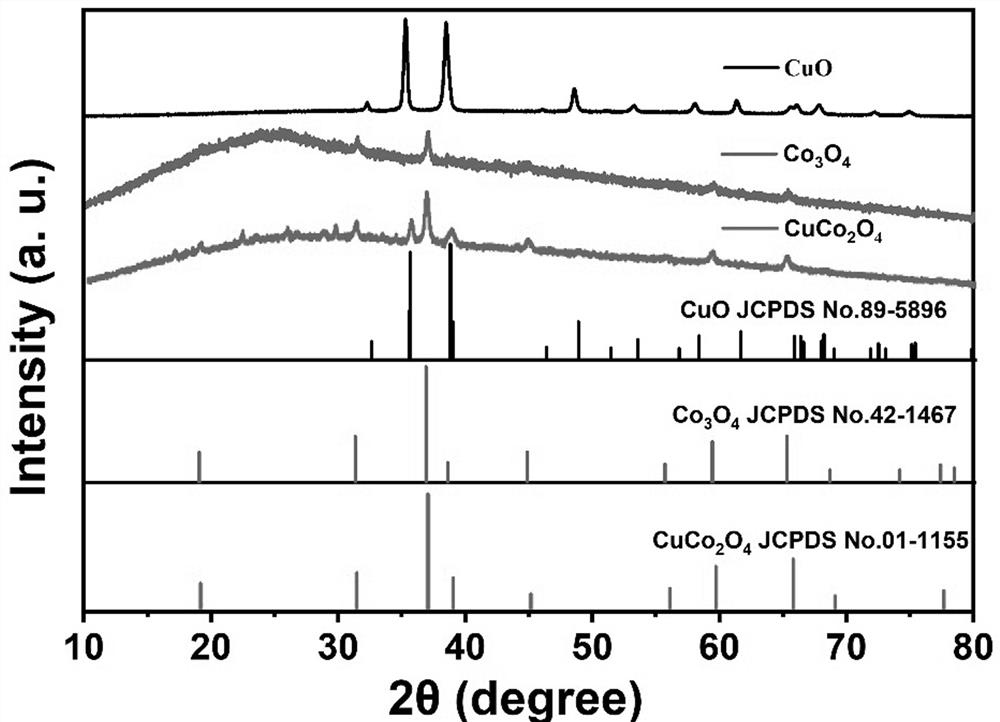

[0054] 1. For the prepared CuCo 2 o 4 The material is subjected to XRD test and morphology test of transmission electron microscope:

[0055] Such as figure 1 as shown, figure 1 Is the prepared CuO, Co 3 o 4 with CuCo 2 o 4 X-ray diffraction pattern of the catalyst.

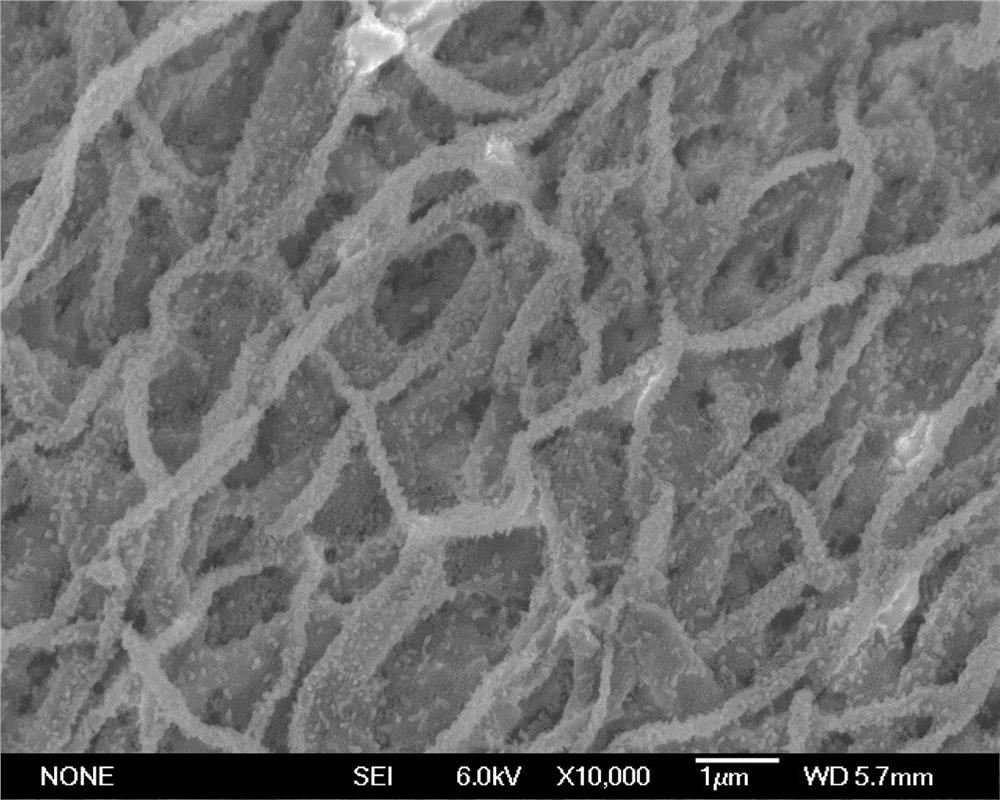

[0056] Such as figure 2 as shown, figure 2 For composite CuCo 2 o 4 SEM image of the catalyst at 10000X.

[0057] image 3 and Figure 4 bimetallic salt CuCo 2 o 4 TEM images of the catalyst at 25000X and 100000X. It can be se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com