Enhanced air floatation-multistage downward flow biofilter treatment system and method for sulfur-containing produced water

A biological filter and treatment system technology, applied in water/sewage multi-stage treatment, biological treatment device, mining wastewater treatment, etc. The effect of strong capacity, low corrosion rate and low suspended solids content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

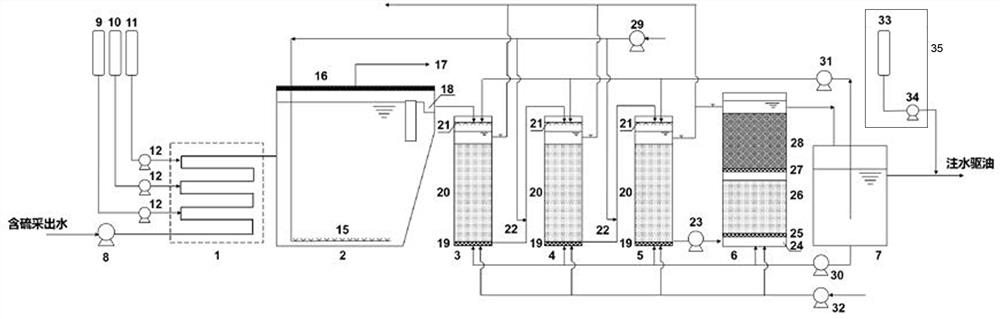

[0027] An enhanced air flotation-multi-stage downflow biological filter treatment system for sulfur-containing produced water, including a mixer 1, an air flotation tank 2, a multi-stage downflow biofilter, a fine filter 6 and a purification jug 7;

[0028] The water inlet of the mixer 1 is connected with a water inlet pump 8, and the mixer 1 is connected with a dosing tank;

[0029] The multi-stage downflow biofilter includes at least two downflow biofilters connected sequentially through aeration pipes 22, and the interior of the downflow biofilter is provided with water distributors 21 from top to bottom , ceramsite filter material layer 20, filter tank supporting layer 19;

[0030] The aeration pipes 22 are all connected with a pressurized dissolved air pump 29, and the pressurized dissolved air pump 29 can increase the dissolved oxygen and head of the filter water inlet for aeration, and the multi-stage downward flow biofilter The water outlet is connected to the bottom...

Embodiment 2

[0039] On the basis of Example 1, the multi-stage downflow biofilter is a three-stage downflow biofilter, including three downflow biofilters connected in sequence through aeration pipes 22, respectively the first The first downflow biofilter 3, the second downflow biofilter 4, and the third downflow biofilter 5.

[0040] The ceramsite filter material layer 20 is composed of heavy ceramsite, the thickness of the ceramsite filter material layer 20 is 1.5~1.8m, and the first-stage downflow biofilter, the second-stage downflow biofilter The ceramsite filter layer 20 of the pool and the third-stage downflow biofilter have a particle size of 3.0mm, 2.0mm, and 2.0mm respectively, and a bulk density of 1.2~1.5g / cm 3 ; The filter support layer 19 is a pebble layer with a particle size of 2-4cm.

Embodiment 3

[0042] On the basis of embodiment 2, utilize described treatment system to process the method for sulfur-containing produced water, comprise the following steps:

[0043] Pump the sulfur-containing produced water into the mixer 1 through the water inlet pump 8, adjust the pH of the sulfur-containing produced water to 6-7, add inorganic flocculants and organic flocculants, mix in the mixer 1, and then enter the air flotation tank 2 , the air-water ratio is adjusted to be 7-10. After the air flotation treatment, the air flotation water flows into the multi-stage downward flow biofilter, and the second-stage downward flow biofilter 4 and the third stage downward flow biofilter are passed through the pressurized dissolved air pump 29. The influent dissolved oxygen of the downflow biofilter 5 is increased for aeration treatment, and the effluent of the multistage downflow biofilter is pumped into the fine filter 6 through the sewage lifting pump 23, and after filtration, the fine fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com