Preparation method of diacerein

A technology of diacerein and sodium acetate, which is applied in the field of preparation of diacerein, can solve the problems of insufficient sources, inapplicability to industrialized large-scale production, and many pollutants, so as to reduce the discharge of three wastes, improve production efficiency, Effect of Simplified Preparation Method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

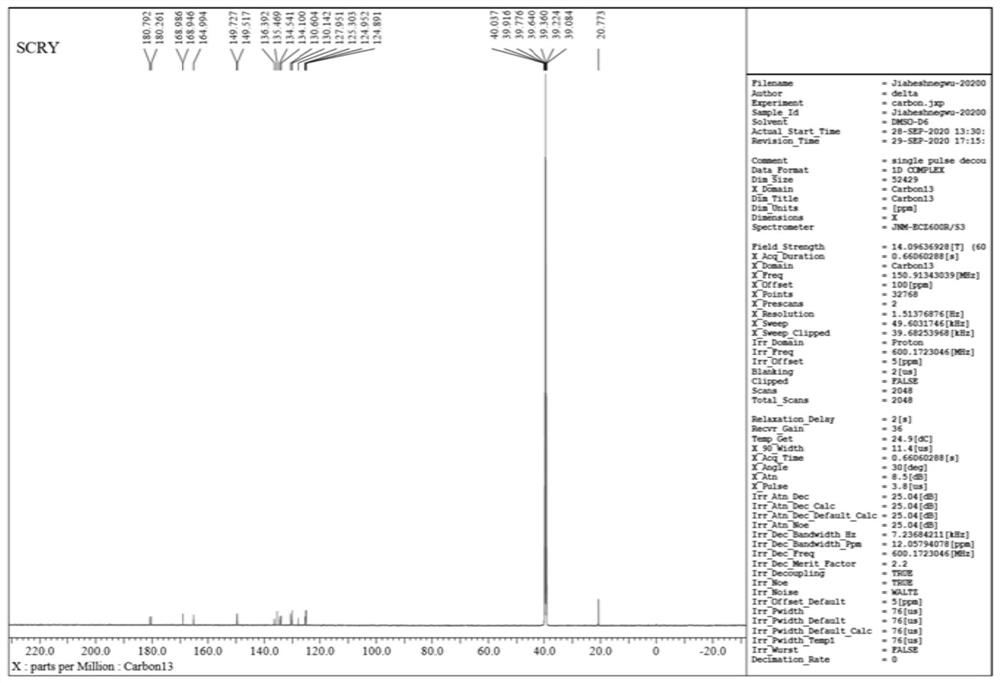

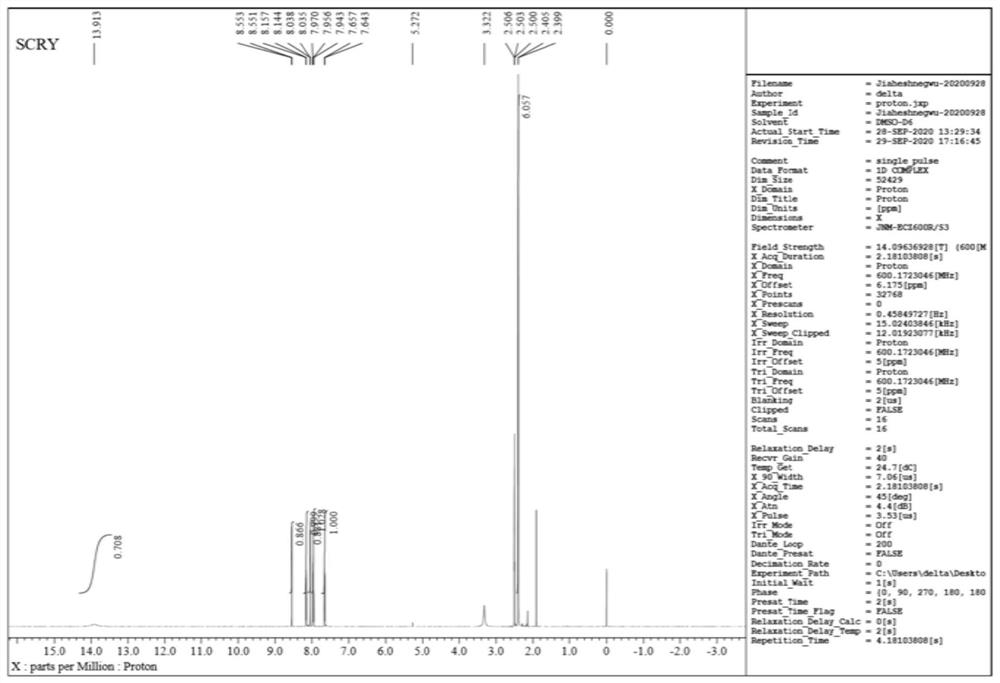

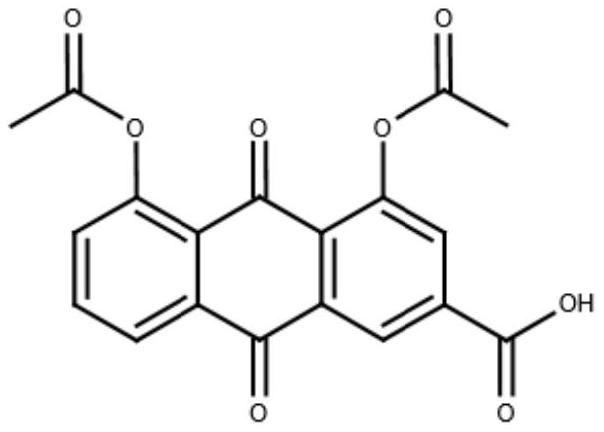

Image

Examples

Embodiment 1

[0051] Add 250kg of glacial acetic acid and 100kg of triacetyl aloe-emodin in the reaction tank, start stirring, and open cold brine to cool down. In the batching tank, add 22kg of manganese chloride tetrahydrate, 22kg of water, stir and dissolve; continue to put in 35kg of chromic anhydride, 23kg of sodium acetate, and 210kg of 85% glacial acetic acid, stir for 40 minutes at normal temperature, and the solid is dissolved and clear, and pumped into the high-level tank for standby. At this time, the temperature in the reaction tank dropped to 0°C, and the cold brine inlet and outlet valves were closed. Close the high-level tank emptying valve, open the compressed air valve, when the pressure in the tank is 0.1mpa, open the high-level tank bottom valve, and quickly press the oxidant into the oxidation tank. When the pressure is 0, close the high-level tank bottom valve, and when the pressure returns to 0.1mpa Then open it quickly, close the compressed air valve when the pressure...

Embodiment 2

[0054] Add 300kg of glacial acetic acid and 100kg of triacetyl aloe-emodin in the reaction tank, start stirring, and open cold brine to cool down. In the batching tank, add 25kg of manganese chloride tetrahydrate and 25kg of water, stir and dissolve. Continue to put in 40kg of chromic anhydride, 25kg of sodium acetate, 250kg of 85% glacial acetic acid, stir at normal temperature for 30 minutes, the solid is dissolved and clear, and pumped into the overhead tank for subsequent use. At this time, the temperature in the reaction tank dropped to 0°C, and the cold brine inlet and outlet valves were closed. Close the high-level tank emptying valve, open the compressed air valve, when the pressure in the tank is 0.1mpa, open the high-level tank bottom valve, and quickly press the oxidant into the oxidation tank. When the pressure is 0, close the high-level tank bottom valve, and when the pressure returns to 0.1mpa Then open it quickly, close the compressed air valve when the pressur...

Embodiment 3

[0057] Add 350kg of glacial acetic acid and 100kg of triacetyl aloe-emodin in the reaction tank, start stirring, and open cold brine to cool down. In the batching tank, add 30kg manganese chloride tetrahydrate and 30kg water, stir and dissolve. Continue to drop into chromic anhydride 35kg, sodium acetate 25kg, concentration is 65% recovery glacial acetic acid 250kg, stir at normal temperature for 30 minutes, the solid is dissolved and clear, is pumped into the overhead tank for subsequent use. At this time, the temperature in the reaction tank dropped to 0°C, and the cold brine inlet and outlet valves were closed. Close the high-level tank emptying valve, open the compressed air valve, when the pressure in the tank is 0.1mpa, open the high-level tank bottom valve, and quickly press the oxidant into the oxidation tank. When the pressure is 0, close the high-level tank bottom valve, and when the pressure returns to 0.1mpa Then open it quickly, close the compressed air valve whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com